Pressurized air-multiple-phase catalyzing method with extraction waste water modification and reinjection at high-temperature in oil field

A technology for oilfield wastewater and catalysts, which is applied in chemical instruments and methods, water aeration, catalyst activation/preparation, etc., can solve problems such as high viscosity of sewage and difficulty in oil-water separation, and achieve cost-saving treatment, simple equipment, and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

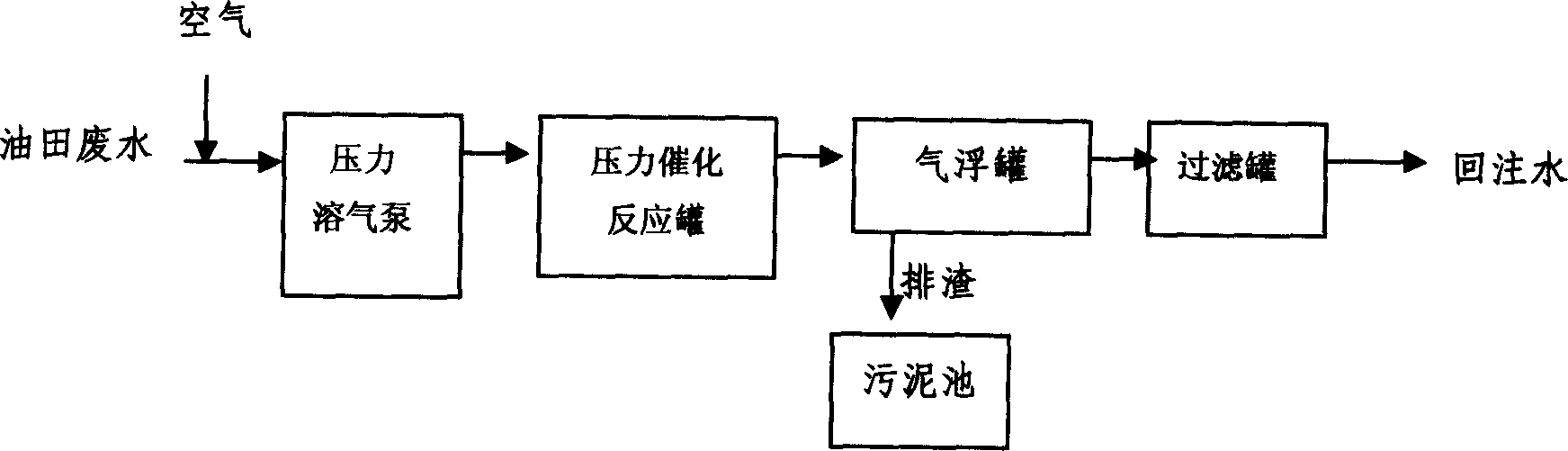

Method used

Image

Examples

Embodiment 1

[0025] M / MnO 2 Catalyst preparation:

[0026] Take 0.6mol / L of Mn(NO 3 ) 3 Solution 100ml, 100 grams of 40 ~ 60 mesh MnO 2 The particles were poured into the impregnating solution and stirred, placed at 85°C for 12 hours, dried at 110°C for 6 hours, then calcined at 350°C for 3 hours, and naturally cooled to room temperature to make a catalyst. The weight of the metal component in the catalyst is: Mn: 5%, the rest is the carrier MnO 2 .

Embodiment 2

[0028] Experiments on pressurized air heterogeneous catalytic modification treatment of oilfield wastewater

[0029] In the heterogeneous catalytic reactor made of stainless steel, two partitions with holes are placed in parallel, two layers of 150ml catalyst prepared according to Example 1 are filled, and water is fed by a dissolved air pump. When the gas-water ratio is 1 / 1, the catalytic reaction time of dissolved gas under pressure is 2min, the reaction temperature is 85°C, and the reaction pressure is 2kg. 4.7mg / l, SS 11.2mg / l and Fe 2+ Under the condition of 4.8mg / l, the comparison experiment of pressurized dissolved air catalysis and pressure dissolved air flotation treatment was carried out, and the results are listed in Table 1.

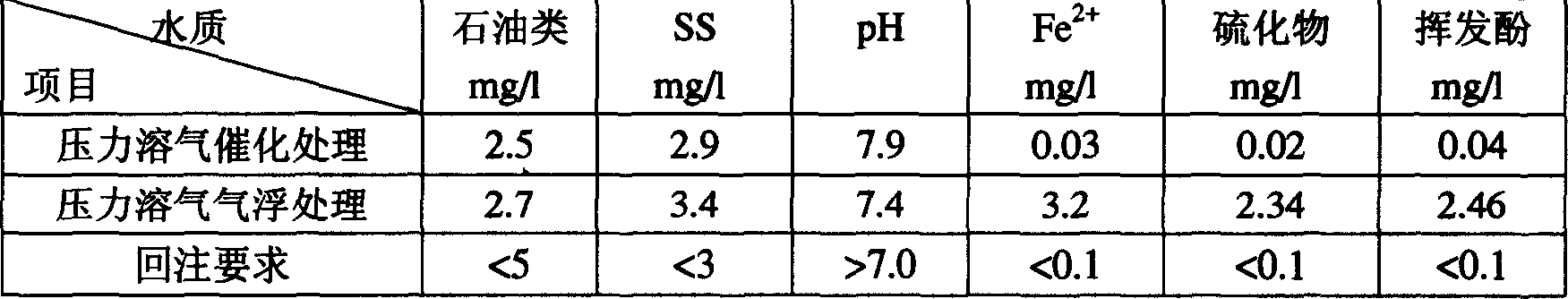

[0030] Table 1. Comparative experimental results of pressurized dissolved air catalysis and pressure dissolved air flotation

[0031]

[0032] It can be known from Table 1 that the high-temperature production wastewater (85°C...

Embodiment 3

[0034] Pressurized Air Heterogeneous Catalytic Pressure Condition Experiments for Oilfield Wastewater

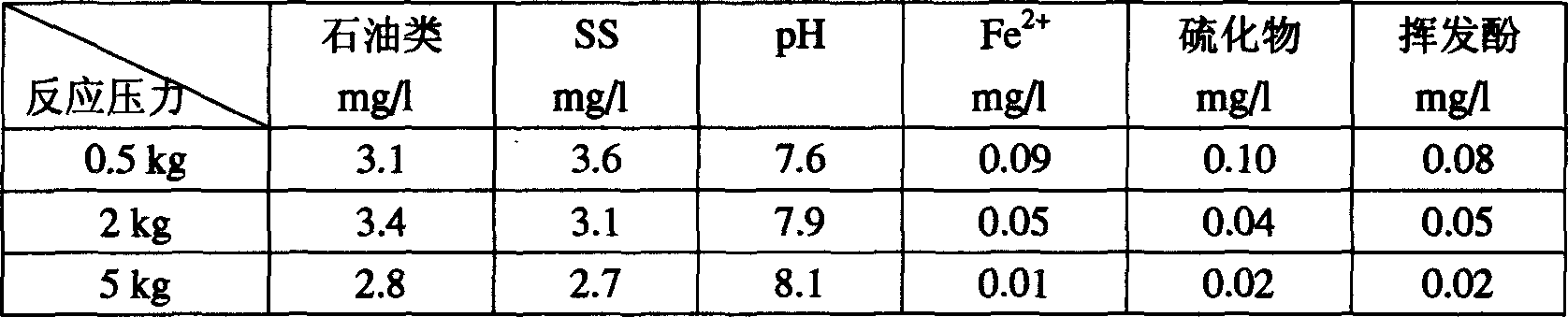

[0035] In the heterogeneous catalytic reactor made of stainless steel, two partitions with holes are placed in parallel, and two layers of 150ml catalyst prepared according to Example 1 are filled, and water is fed by a dissolved air pump. When the ratio of aeration gas to water is 1 / 1, the catalytic reaction time of pressure dissolved air is 2min, and the reaction temperature is 85°C. l. Under the conditions of SS 11.2mg / l and Fe2+4.8mg / l, and different dissolved air pressures, the wastewater was further catalytically treated, and the results are listed in Table 2.

[0036] Table 2. Results of heterogeneous catalytic treatment of oilfield wastewater under different pressures

[0037]

[0038] From the experimental results in Table 2, it can be known that using the pressurized air heterogeneous catalytic oxidation technology to treat the polymer-containing high-temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com