Comprehensive recovery for bullion ore with various metals

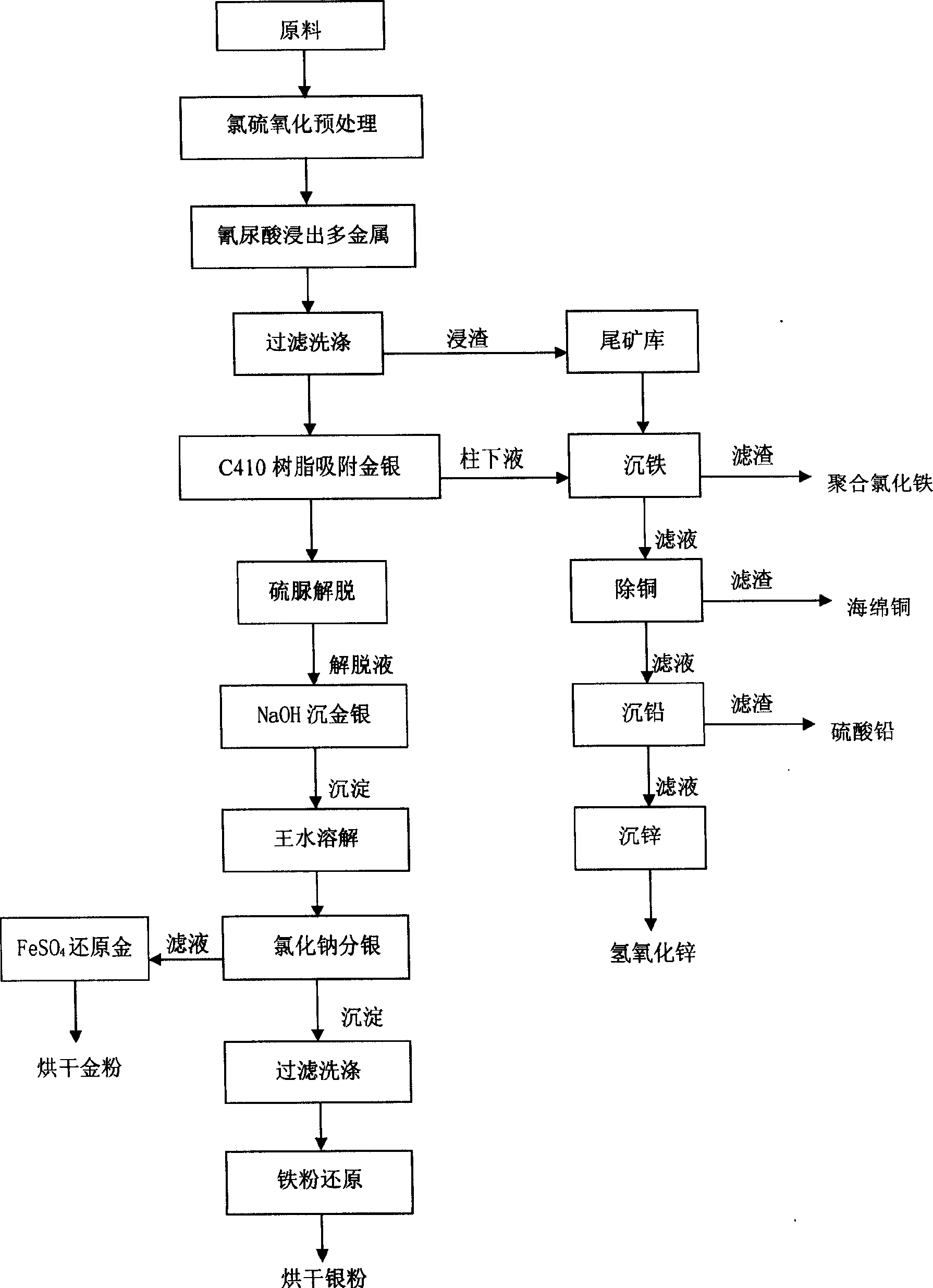

A recovery method and polymetallic technology, applied to silver and polymetallic, low-temperature chlorine-sulfur oxidation pretreatment, can solve the problems of comprehensive recovery of polymetallic gold and silver ore, long leaching time, equipment corrosion, etc., and achieve obvious economic benefits and environmental benefits, strong mineral adaptability, and fast leaching speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Take 30Kg of high-carbon and high-sulfur gold concentrate powder, add 4.5Kg of solid NaCl (about 15%), stir and mix, put it into a continuous rotary kiln, heat to 350°C, and keep it warm for 3.5 hours for pretreatment. Immerse the sand in a solution of 20% NaCl and 11% sodium hypochlorite at a solid-liquid ratio of 1:4, add 10Kg / ton of cyanuric acid (about 0.36Kg) according to the weight of the calcined sand, stir and leach for 6 hours, and then filter and wash to form Precious liquid and leaching slag, the leaching slag is discharged into the tailings pond, the precious liquid passes through the C410 resin exchange column at a flow rate of less than 100ml / min to adsorb gold and silver to form gold-loaded, silver-laden resin and sub-column liquid, thereby separating gold, silver and polymetallic separate. Use 3% thiourea to elute the gold-silver resin to form a gold-silver liquid. The volume ratio of the eluent to the gold-silver resin is 30:1. NaOH is added to the gold...

Embodiment 2

[0030] The material is a high-carbon and high-sulfur silver concentrate. Take 30Kg of the material and add 6Kg of solid NaCl (about 20%) to stir and mix it, then put it into a continuous rotary kiln and heat it to 350°C for 4 hours. The calcine is mixed according to the ratio of solid to liquid 1:6, the NaCl concentration of the leaching solution is 20%, the concentration of sodium hypochlorite is 13%, and 15 kg / ton (about 0.54 kg) of cyanuric acid is added according to the weight of the calcine, stirred and leached for 8 hours, filtered Washing, leaching slag enters the tailings pond. The immersion liquid enters the multi-metal recovery process, and the flow rate is controlled below 100mL / min to absorb gold and silver through the C410 resin adsorption column. Cu, Pb, Zn, and Fe are in the effluent, thereby separating them from Au and Ag. The gold-loaded resin was eluted with 3% thiourea, and the volume ratio of the eluent to the gold-silver resin was 30:1. NaOH was added to t...

Embodiment 3

[0035] Material is the calcined sand after oxidation roasting, gets 30Kg material and puts into stirring tank, immerses in the solution that contains 5%NaCl and 12% sodium hypochlorite, makes solid-liquid ratio be 1: 5, adds cyanuric acid 8kg / ton by calcined sand weight ( about 0.28Kg), stirred and leached for 6 hours, filtered and washed, the leached slag was put into the tailings pond, the leached liquid was adsorbed by the C410 resin adsorption column to absorb gold and silver, the flow rate was controlled below 100mL / min, Cu, Pb, Zn, Fe were in the effluent, Separated from Au and Ag. The gold-silver loaded resin was eluted with 3% thiourea, the volume ratio of the eluent to the gold-silver loaded resin was 30:1, NaOH was added to the eluent to make the pH = 11, and a hydroxide precipitate was formed, which was filtered and washed , add 1:1 aqua regia to the gold and silver precipitate to dissolve until transparent, add sodium chloride until the black silver chloride precip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com