Gel type perspex/organic leituo stone electrolyte and prepn. process

A technology of polymethyl methacrylate and rectorite, which is applied in the field of gel-type polymethyl methacrylate/organic rectorite electrolyte and its preparation, can solve problems such as not obvious effect, and achieve good size space The effect of stability, wide applicability and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The preparation of organic rectorite: 50g of sodium-based rectorite is dissolved in water and stirred for slurrying, and 30g of organic surfactant C 12 (or C 16 、C 18 ) quaternary ammonium salt dissolved in water at 40-50°C, then slowly pour the aqueous surfactant solution into the slurry, homogeneously disperse for 10 minutes, then transfer to a three-necked flask, and keep warm at 80-85°C for 12 hours. transferred to a beaker, and then washed with deionized water until AgNO 3 The solution does not detect Cl - So far, organic rectorite 12-OREC, 16-OREC and 18-OREC can be obtained after drying and grinding.

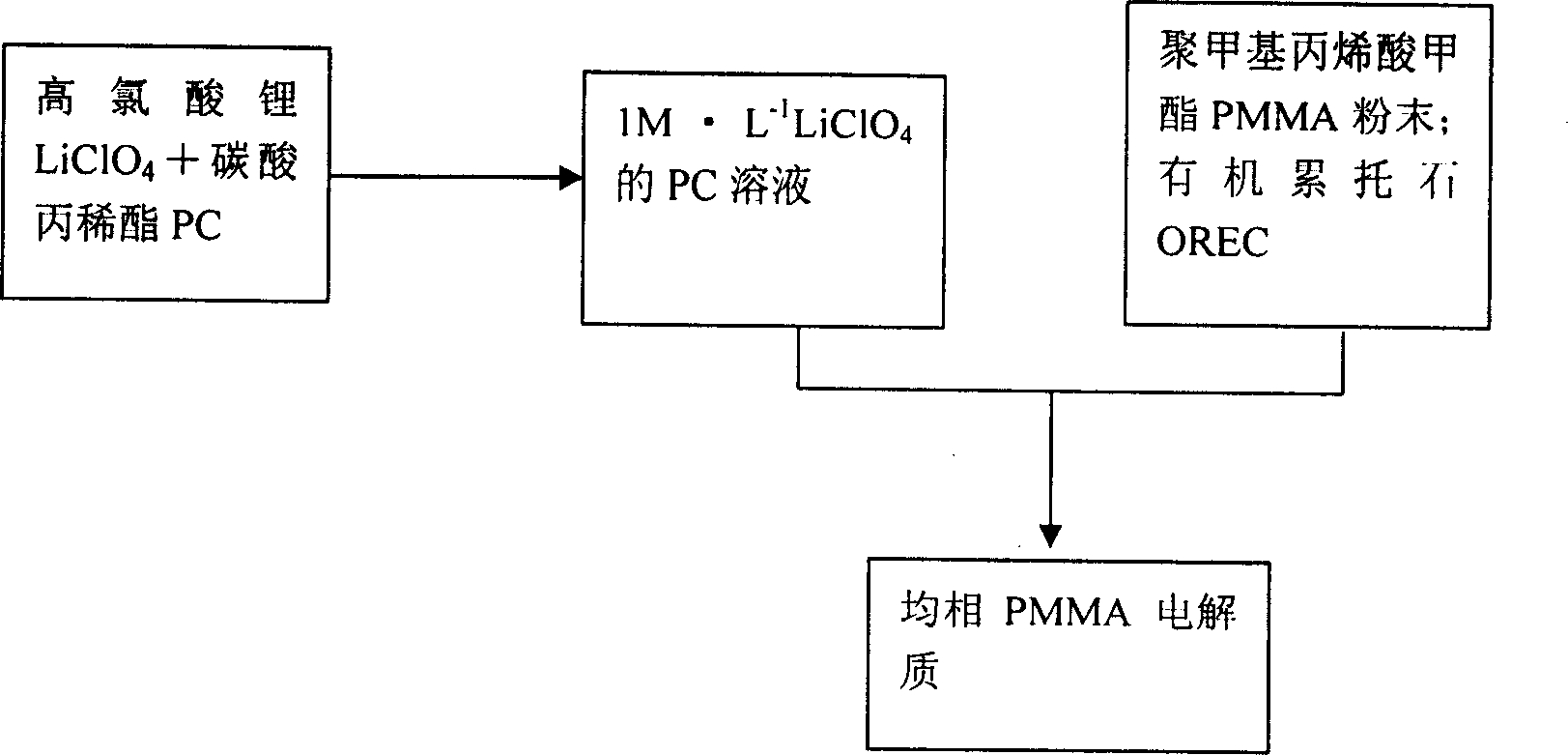

[0019] Preparation of gel-type polymethyl methacrylate / organic rectorite electrolyte: lithium perchlorate LiCiO 4 Dissolve in propylene carbonate PC to form an organic solution. Dissolving the prepared polymethyl methacrylate and modified organic rectorite in Li + In the salt solution, stir at 50-60°C until homogeneous. Then pour the gel solution onto a glas...

Embodiment 1

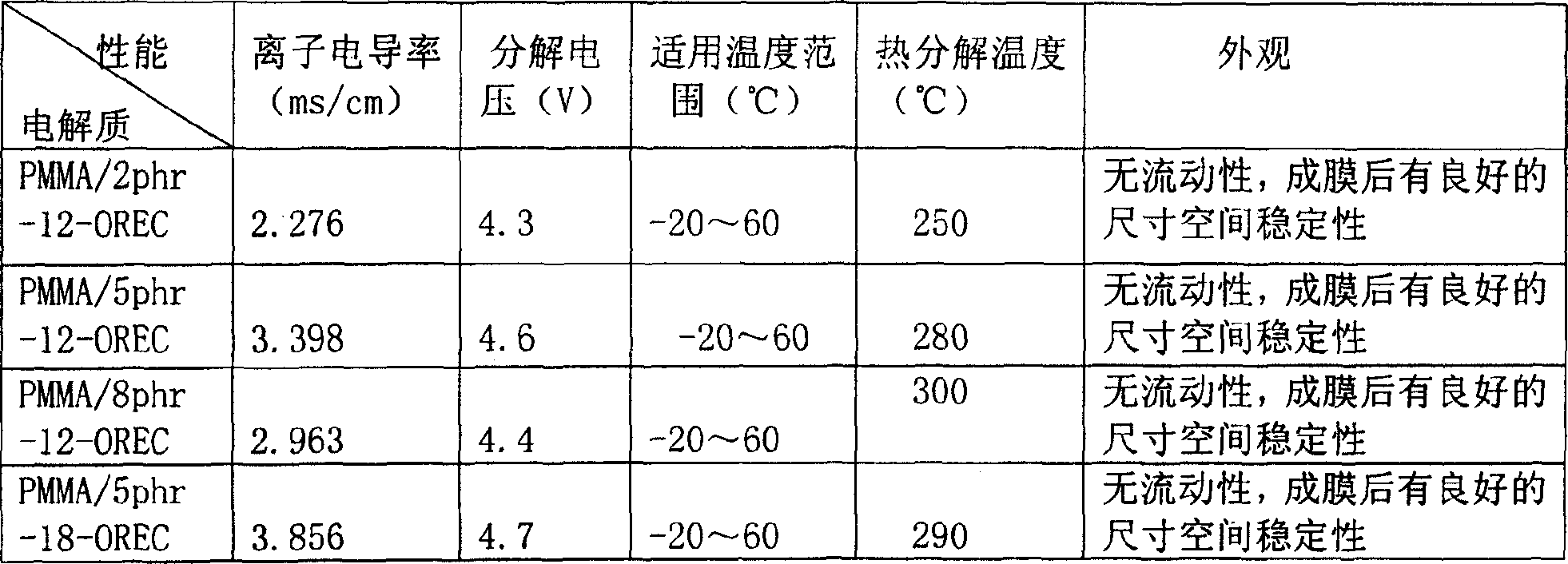

[0020] Implementation example 1: lithium perchlorate LiCiO 4 Dissolve in propylene carbonate PC to make 1M·L -1 20g self-made polymethyl methacrylate and 2g self-made organically modified rectorite (12-OREC) were dissolved in 80g of prepared PC organic solution at about 55°C with stirring until it became uniform phase colloid, and then pour the gel solution on a glass plate to form a film, and place it in a desiccator at room temperature for 12 hours to obtain a gel-type PMMA / 2phr-12-OREC electrolyte. It is found that under this ratio, the prepared polymethyl methacrylate / organic rectorite electrolyte has good steric stability and mechanical properties, and well meets the requirements for ion conductivity as an electrolyte for lithium-ion batteries .

Embodiment 2

[0021] Implementation example 2: lithium perchlorate LiCiO 4 Dissolve in propylene carbonate PC to make 1M·L -1 20g self-made polymethyl methacrylate and 5g self-made organically modified rectorite (12-OREC) were dissolved in 80g prepared PC organic solution at about 55°C with stirring until it became uniform phase colloid, and then pour the gel solution on a glass plate to form a film, and place it in a desiccator at room temperature for 12 hours to obtain a gel-type PMMA / 5phr-12-OREC electrolyte. It is found that under this ratio, the prepared polymethyl methacrylate / organic rectorite electrolyte has good steric stability and mechanical properties, and well meets the requirements for ion conductivity as an electrolyte for lithium-ion batteries .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com