Method for polymerizing nano silicon dioxide/polymethyl methacrylate gel polymer electrolyte initiated by one-step method

A technology of polymethyl methacrylate gel and methyl methacrylate, which is applied in the interdisciplinary field of electricity and materials science, can solve the problems of high viscosity of the system, complex process, and low degree of dispersion of nanoparticles, and achieve improved stability The effect of sex and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

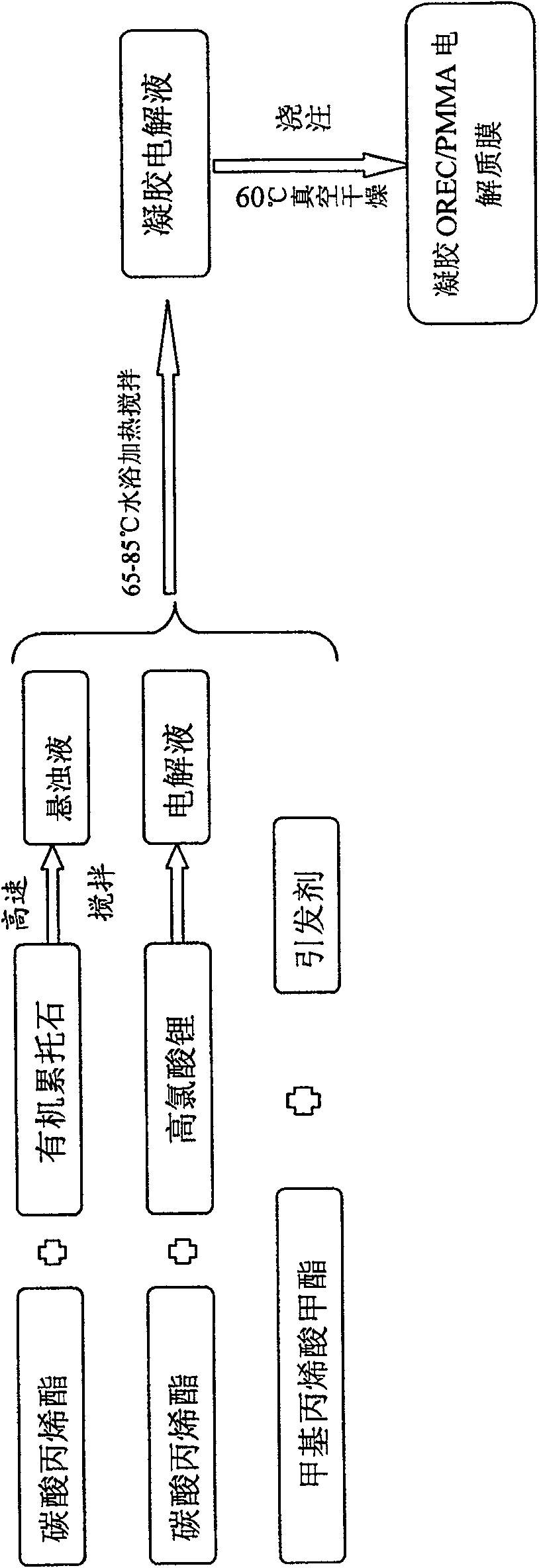

Method used

Image

Examples

Embodiment 1

[0025] 2.5g lithium perchlorate LiCiO 4 Dissolve in 27.5g propylene carbonate PC to make 1M·L -1 30g of organic solution; 20g methyl methacrylate, 0.05g azobisisobutyronitrile, 1.5g nano-SiO2, 30g organic electrolyte, fully mixed and stirred in an 80°C water bath for 2.5 hours, and poured the obtained colloidal electrolyte Form a thin film and dry it in a vacuum atmosphere at 60°C for 8 hours to obtain a silica / polymethyl methacrylate gel polymer electrolyte (1phr-SiO 2 / PMMA). And found that under this ratio, the silicon dioxide / polymethyl methacrylate (SiO 2 / PMMA) gel polymer electrolyte has good steric stability and mechanical properties, and well satisfies the requirement of ionic conductivity as an electrolyte for lithium-ion batteries.

Embodiment 2

[0027] 2.5g lithium perchlorate LiCiO 4 Dissolve in 27.5g propylene carbonate PC to make 1M·L -1 30g of organic solution; 20g methyl methacrylate, 0.05g dibenzoyl peroxide (BPO), 3g nano-SiO2, 30g organic electrolyte, fully mixed and stirred in an 80°C water bath for 2.5 hours to obtain colloidal electrolyte The solution was poured into a thin film, and dried in a vacuum atmosphere at 60°C for 8 hours to obtain a silica / polymethyl methacrylate gel polymer electrolyte (2phr-SiO 2 / PMMA). And found that under this ratio, the silicon dioxide / polymethyl methacrylate (SiO 2 / PMMA) gel polymer electrolyte has good steric stability and mechanical properties, and well satisfies the requirement of ionic conductivity as an electrolyte for lithium-ion batteries.

Embodiment 3

[0029] 2.5g lithium perchlorate LiCiO 4 Dissolve in 27.5g propylene carbonate PC to make 1M·L -1 30g of organic solution; 20g of methyl methacrylate, 0.05g of azobisisobutyronitrile, 5g of nano-SiO2, 30g of organic electrolyte, fully mixed and stirred in an 80°C water bath for 2.5 hours, and poured the obtained colloidal electrolyte into The film was dried under vacuum at 60°C for 8 hours to obtain a silica / polymethyl methacrylate gel polymer electrolyte (5phr-SiO 2 / PMMA). And found that under this ratio, the silicon dioxide / polymethyl methacrylate (SiO 2 / PMMA) gel polymer electrolyte has good steric stability and mechanical properties, and well satisfies the requirement of ionic conductivity as an electrolyte for lithium-ion batteries.

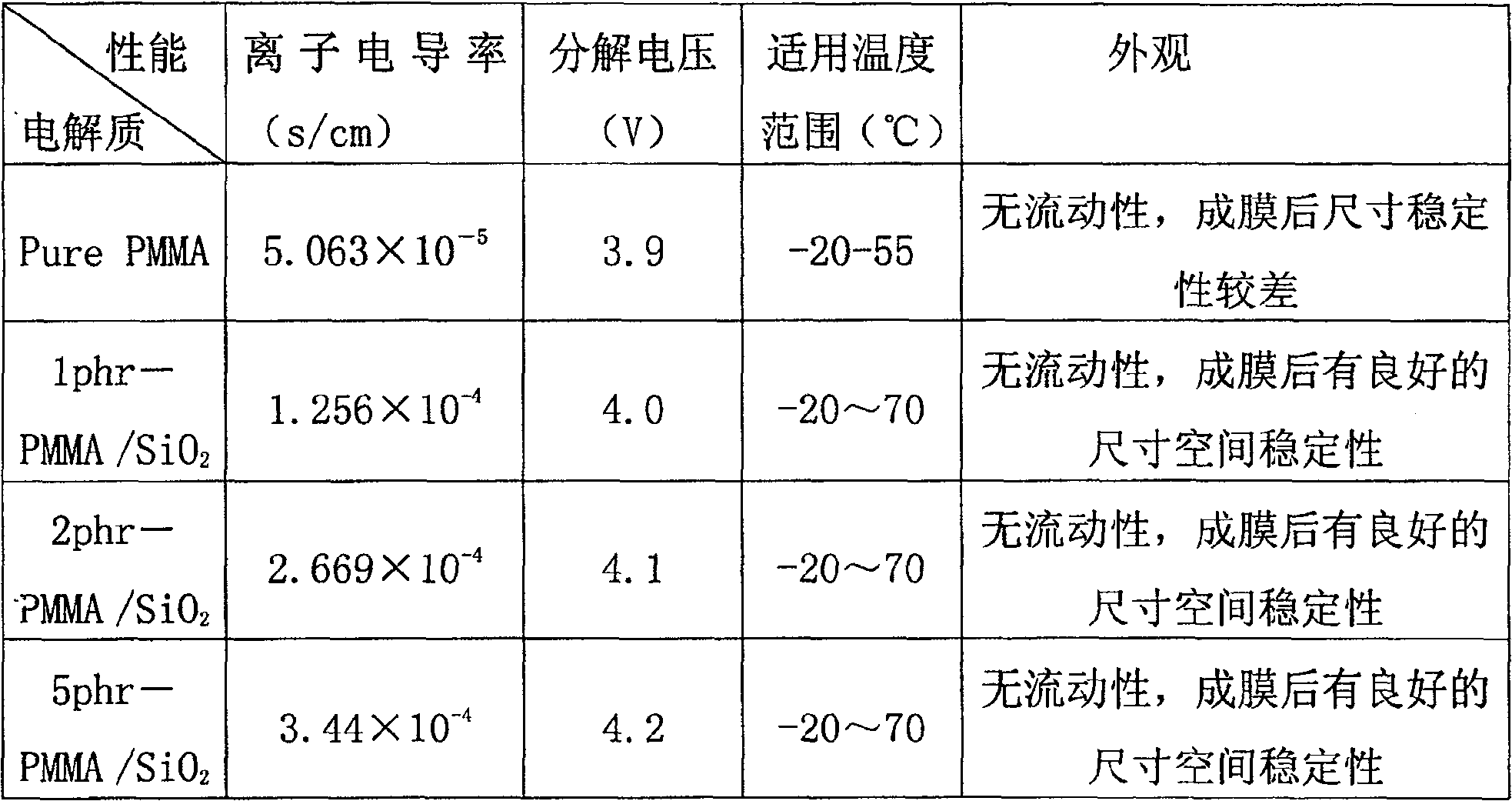

[0030] The concrete properties of the gel electrolyte system that three kinds of embodiments obtain are as follows:

[0031]

[0032] ※All measured at 25℃

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com