Hydrogen fluoride adsorbent and its preparation method and uses

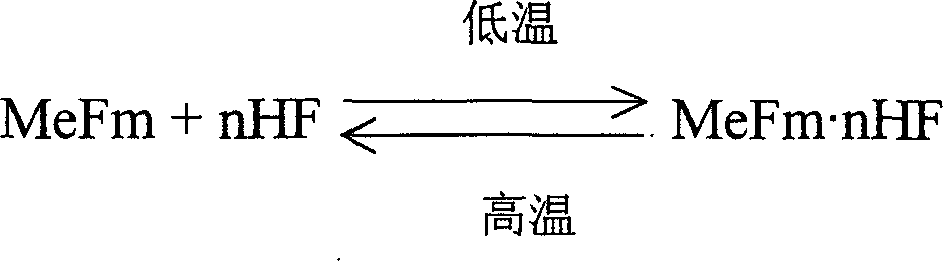

A hydrogen fluoride and adsorbent technology, applied in the field of hydrogen fluoride adsorbent, can solve the problems of high equipment requirements, difficult separation and recovery of hydrogen fluoride, fluorine pollution, etc., and achieves the effect of high adsorption rate and selectivity, full and effective utilization, and avoiding fluorine pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0020] Weigh 20kgKF, 50kgNaF, and 20kgKF·HF into a mixer and mix evenly, take it out and add it to a ball mill to crush it into powders of about 100 meshes, take it out and add it to the mixer and add 5 kg of water glass with a modulus of 3, mix it evenly, and then add an appropriate amount of water. Make it reconcile into a dough shape, extrude it with an extruder, cut it into particles of φ4-6×6-8mm, put it in an oven at 105-110°C, and dry it for 24 hours.

[0021] Adsorbent preparation example 2

[0022] Weigh 30kgKF, 30kgNaF, 40kgBaF 2 (do not add hydrogen fluoride), except that, other are all implemented by Preparation Example 1

[0023] Adsorbent preparation example 3

[0024] Weigh 40kgLiF, 30kgBaF 2 , 30kgKF.HF are put into mixer and mix homogeneously, take out and add ball mill and be pulverized into powders of about 100 orders, take out and add mixer, and add 5kg silica-containing alumina powder, other are implemented by preparation example 1.

[0025] Adsorbent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com