Process for preparing low phytic acid rapeseed protein concentrate by using water and ethanol

A technology of rapeseed protein concentrate and phytic acid, which is applied to the protein composition, protein food composition, and application of vegetable seeds, can solve the problems of waste water discharge, high protein loss rate, and difficulty in industrialized production, so as to avoid pollution and recover. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

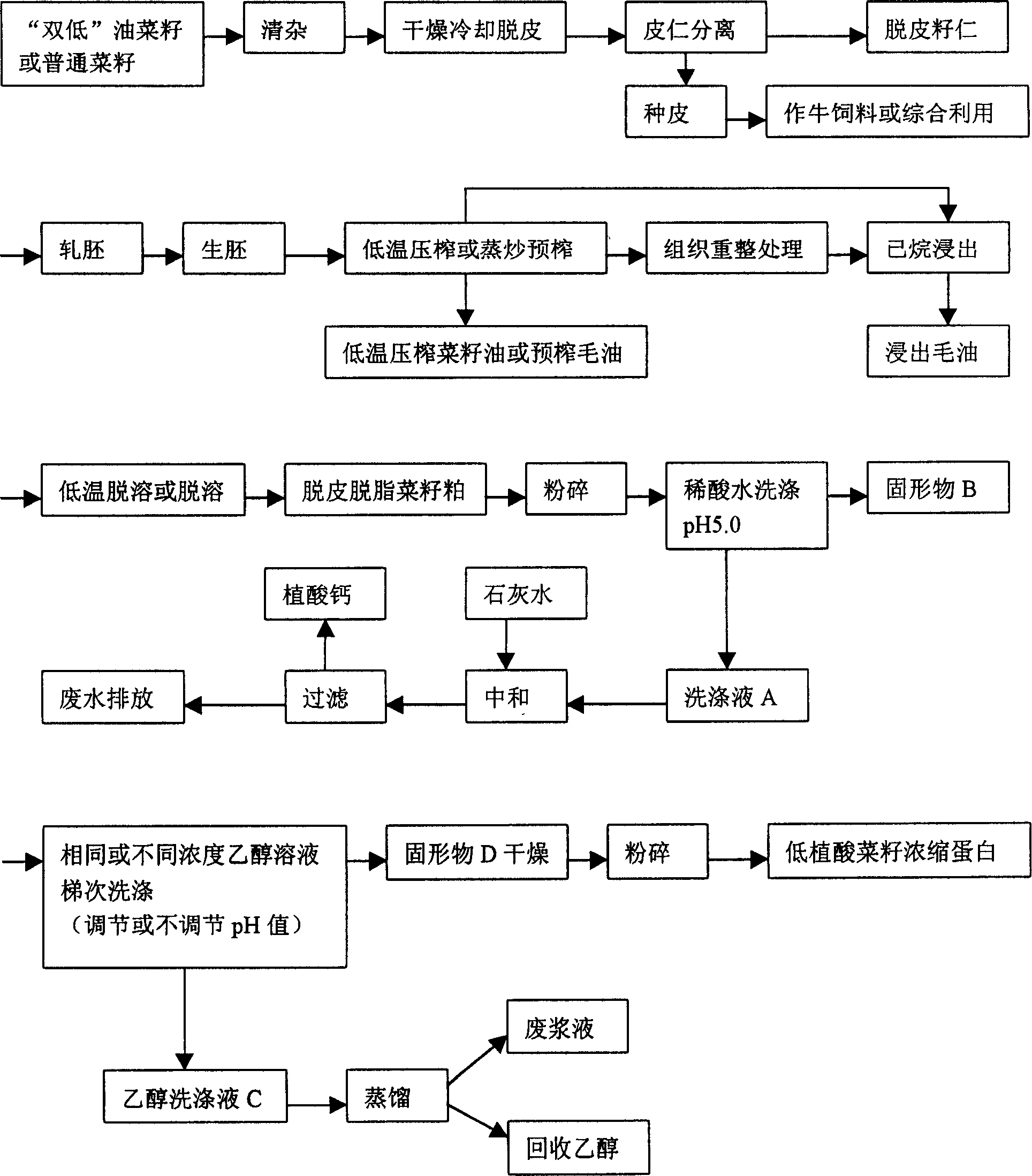

[0013] see figure 1 , a method for preparing low-phytic acid rapeseed protein concentrate by using water and ethanol, the specific process is: after cleaning the "double-low" rapeseed or common rapeseed, drying to 10% moisture, controlling the drying temperature of the material temperature at 40°C to prevent protein denaturation, and then use a rapeseed peeling and kernel skin separator for peeling, the peeling rate is 90%, and the seed coat can be used as cattle feed or comprehensive utilization; the peeled rapeseed kernels are steamed and fried after rolling embryos Mature embryos (pressed at low temperature or pre-pressed by steaming and frying), pre-pressed oil with a screw press, (tissue reforming treatment, hexane leaching, leaching crude oil) pre-pressed cakes are leached and desolvated to make rapeseed dehulled and defatted meal , crushed to 50 mesh, first washed with dilute acid water with a pH value of 5.0 to remove phytic acid, stirred and washed at 25°C, controlled...

Embodiment 2

[0017] A method for preparing concentrated low-phytic acid rapeseed protein by using water and ethanol. After cleaning the "double-low" rapeseed or ordinary rapeseed raw materials, dry them until the moisture content is 6%, and control the drying temperature of the materials at 60°C to prevent The protein is denatured, and then peeled with a rapeseed peeling and kernel skin separator. The peeling rate is 96%. After the peeled rapeseed kernels are rolled, the raw embryos are pressed with a low-temperature screw oil press to extract oil, and the cake is reorganized Treatment (including particle size adjustment, texturization, or granulation), followed by leaching to oil production, and after low-temperature precipitation at 60°C, rapeseed dehulled and degreased meal was obtained, crushed to 100 mesh, and firstly measured with a pH value of Wash with 5.0 dilute acid water to remove phytic acid, stir and wash at 55°C, control the liquid-solid ratio to 5:1, wash for 0.5 hours each t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com