High-speed treating apparatus for organic waste

An organic waste, high-speed treatment technology, applied in biological sludge treatment, aerobic process treatment, chemical/physical process, etc., can solve problems such as increased agitator load, unsmooth air circulation, unbalanced load, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings.

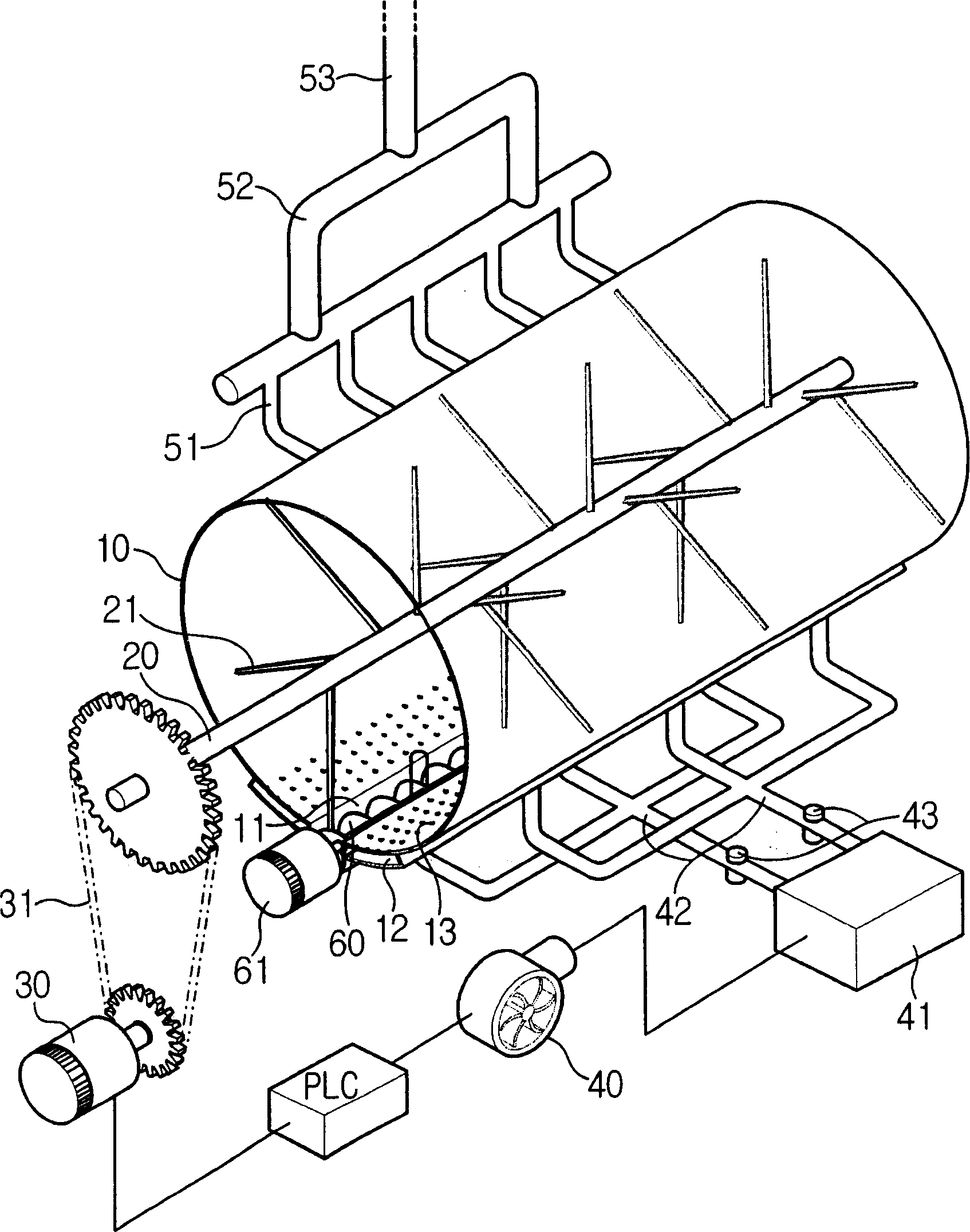

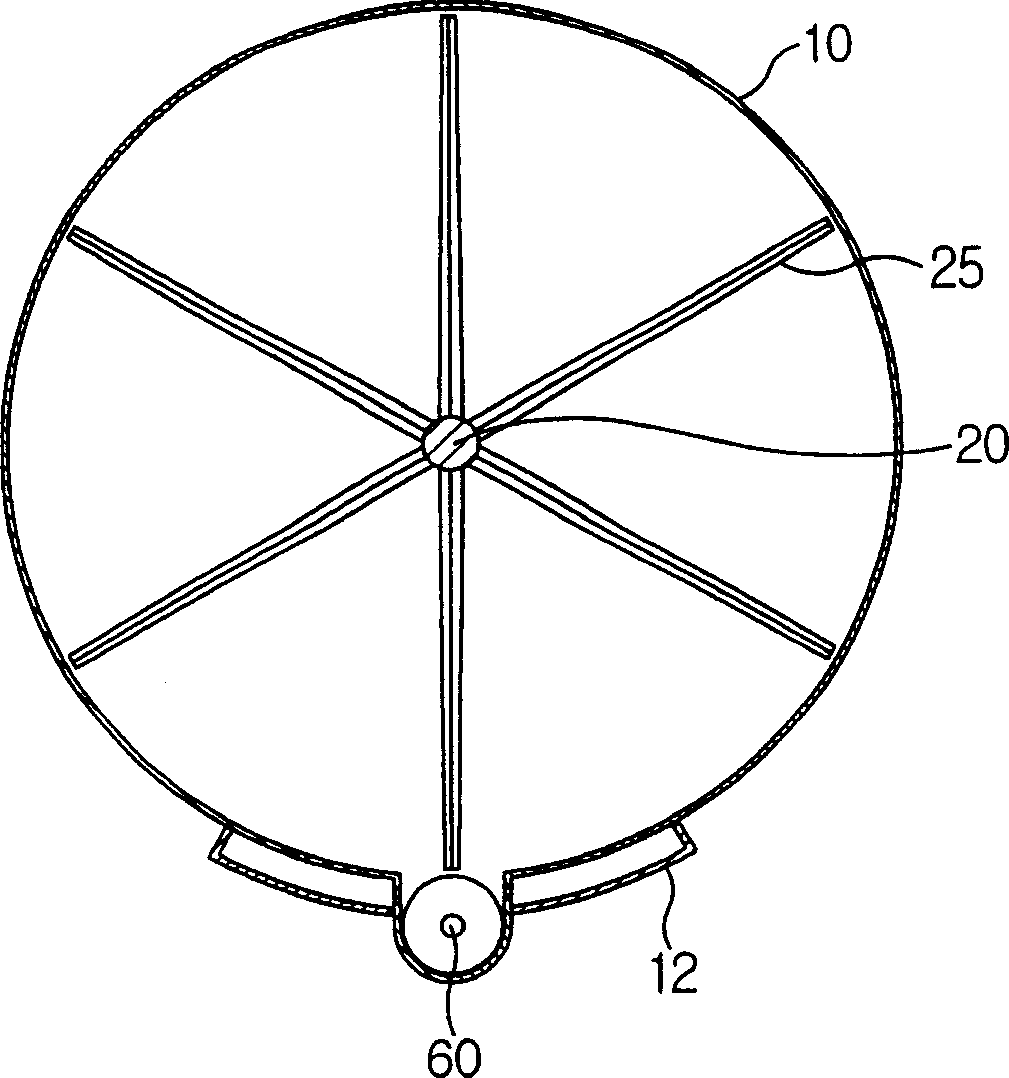

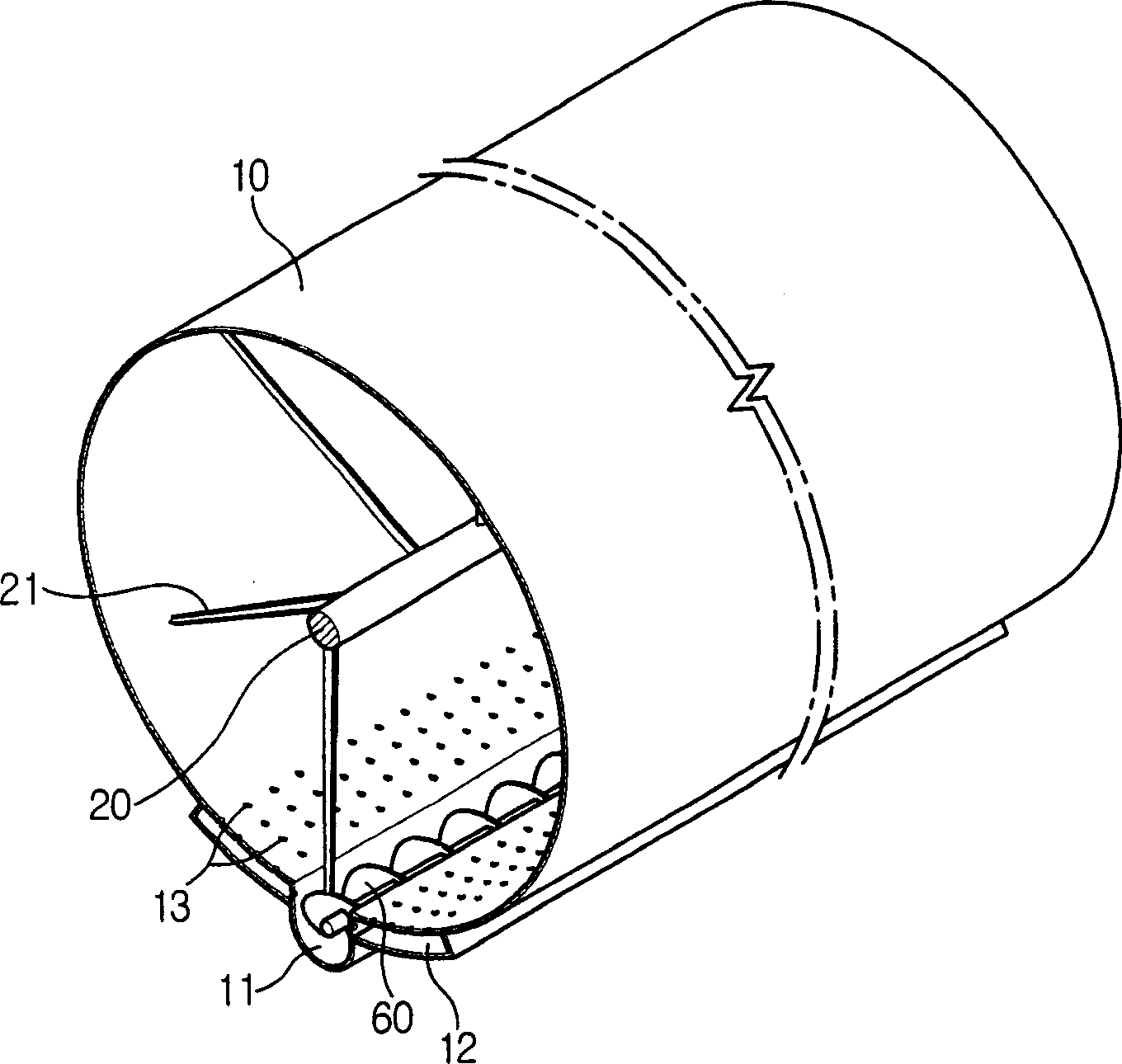

[0042] Figure 1 to Figure 7 It is an explanatory diagram of the high-speed organic waste processing equipment of the present invention.

[0043] As shown in the figure, the present invention comprises: a sealed cylindrical reactor (10); a stirring rotating shaft ( 20); in order to drive the first drive motor (30) connected by the transmission chain (31) in order to drive the stirring rotating shaft (20); there is an internal organic (food) waste that can be disposed on the lower side of the above-mentioned reactor (10). An air supplier (40) for supplying air; the upper side of the above-mentioned reactor (10) has a humid gas processor (50) capable of sucking, treating and discharging the humid gas generated by the internal organic waste. In order not to be affected by the first driving motor (30) when it is forward / reversing and to prevent the leakage of moist gas o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com