Cerium oxide nano materials and its preparation and use

A technology of nanomaterials and cerium oxide, applied in chemical instruments and methods, polycrystalline material growth, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of low initial solution concentration, low yield, and reduced product purity, etc. problem, to achieve the effect of cheap precipitant and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

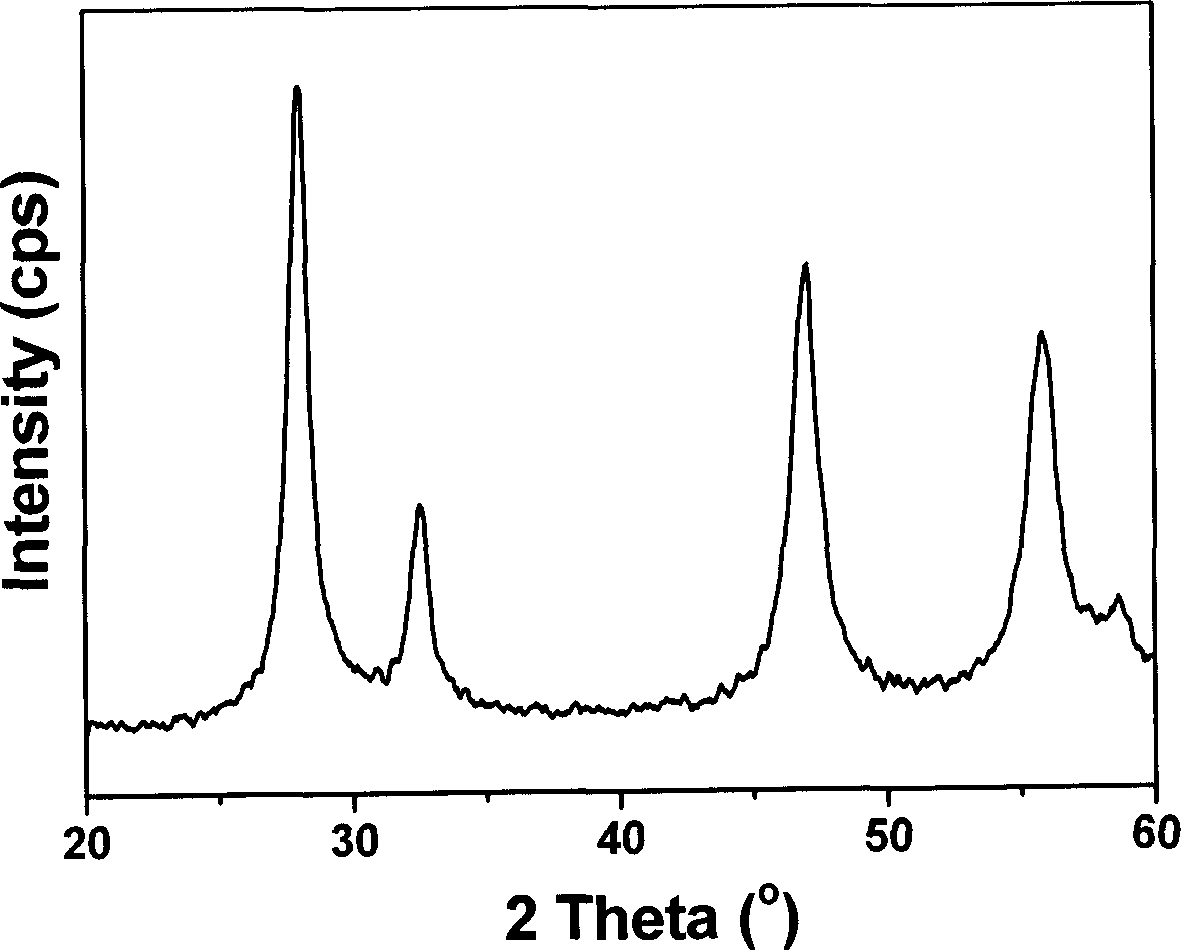

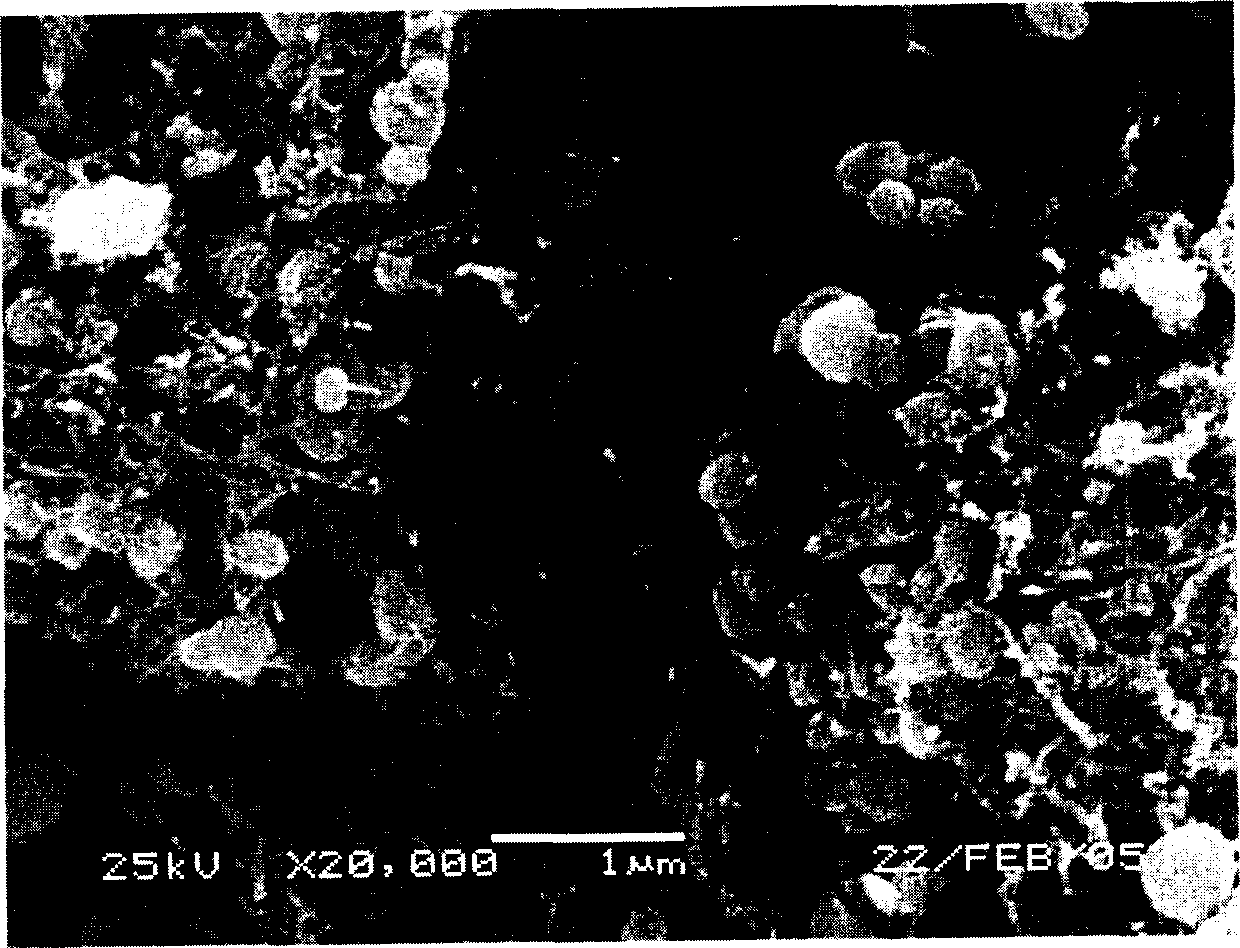

[0036] Preparation of precursor solution: 1 g Ce(NO 3 ) 3 ·6H 2 O was added to 4.5g of urea, then deionized water was added, dissolved under stirring, and finally diluted to 40ml with water to obtain a precursor solution; the above solution was poured into a hydrothermal reaction kettle, and treated with 140°C hydrothermal treatment, and the temperature was 2 hours, take it out and cool to room temperature, filter with suction, wash, dry at 120°C for 2 hours, and bake at 450°C for 1 hour. figure 1 X-ray powder diffraction pattern for the product. figure 2 It is the scanning electron microscope result of the product, which shows that the calcined sample is nanofiber. BET test shows that the specific surface area is 100m 2 / g.

Embodiment 2

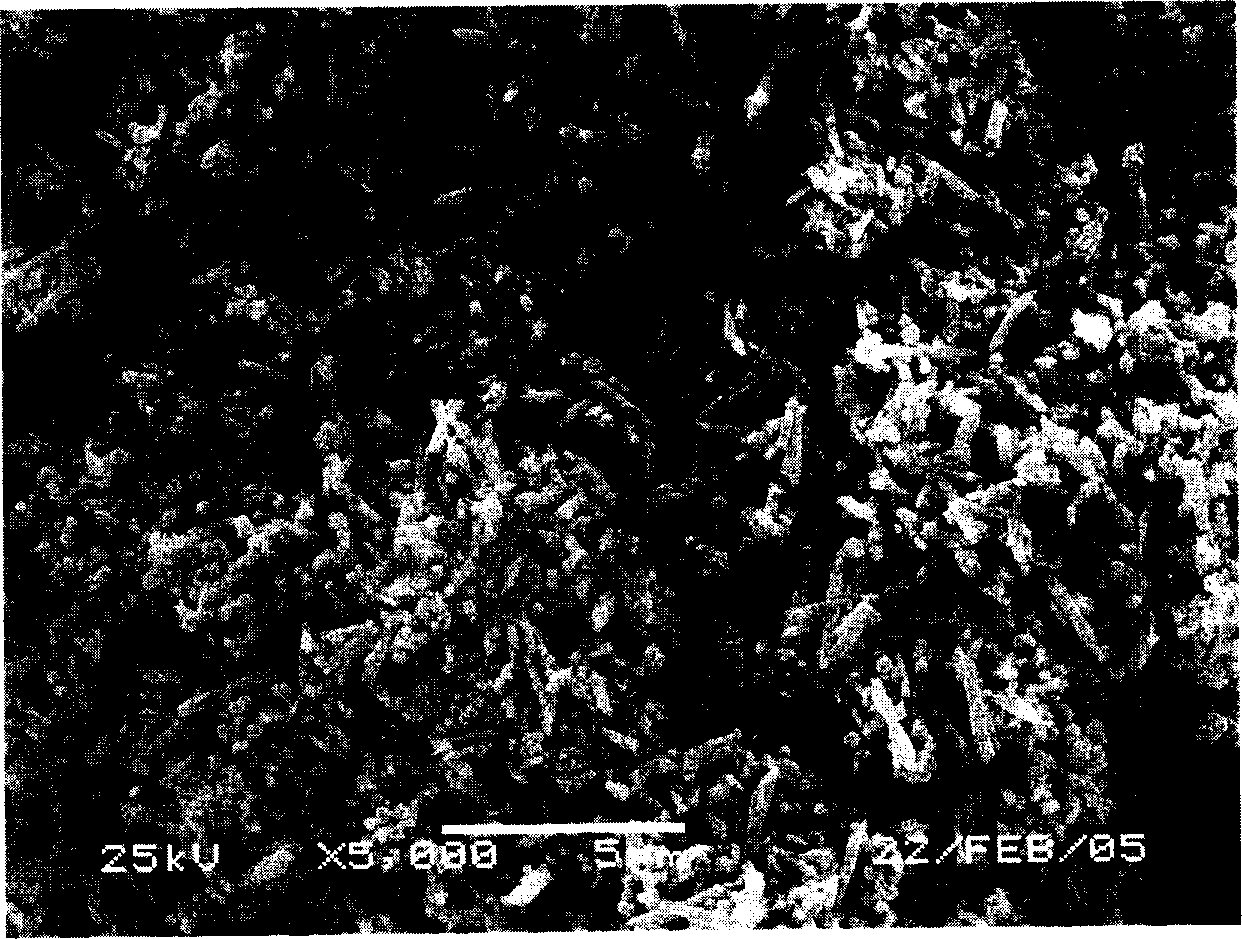

[0038] Ce(NO 3 ) 3 ·6H 2 The add-on of O is 2g, all the other conditions are with embodiment 1. SEM ( image 3 ) measured that the roasted sample is a nanorod with a diameter of 20-100 nanometers and a length of 100 nanometers-3 microns.

Embodiment 3

[0040] Ce(NO 3 ) 3 ·6H 2 The add-on of O is 10g, all the other conditions are with embodiment 1. SEM ( Figure 4 ) measured that the roasted sample is a nanorod with a diameter of 40-100 nanometers and a length of 100 nanometers-2 microns. BET test shows that the specific surface area is 120m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com