Method for preparing immobilized lipase attapulgite clay

A technology for immobilizing lipase and attapulgite, applied in directions such as hydrolase immobilized on or in an inorganic carrier, can solve problems such as no reports on large-scale industrialization, and improve the utilization rate and application scope of the enzyme , good guiding role, the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

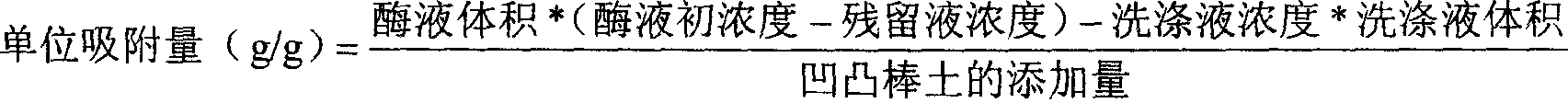

Method used

Image

Examples

Embodiment 1

[0038] The attapulgite used is the raw ore of attapulgite collected from Xuyi, and its composition and content composition are shown in Table 1:

[0039] Element

MgO

al 2 o 3

SiO 2

SO 2

K 2 o

CaO

TiO 2

MnO

Fe 2 o 3

Content (%)

8.2

11.9

63.8

1.0

1.9

1.6

1.4

0.5

9.7

[0040] The lipase activity used is 5000u / g.

[0041] (1) Acid treatment of attapulgite: add 300 ml of 2mol / l hydrochloric acid to 30 grams of attapulgite, stir at 50°C for 3 hours, centrifuge, then wash with deionized water until detected with 0.1mol / l silver nitrate solution After being free of chloride ions, it is dehydrated by centrifugation, dried and pulverized.

[0042] (2) Calcium chloride treatment: Weigh 20g of the above-mentioned acid-treated attapulgite, add 1mol / l of CaCl 2 Solution 50ml, stirred at 55°C for 1 hour, centrifuged at a slow speed (to prevent attapulgite from accumulat...

Embodiment 2

[0048] Acid treatment of attapulgite: add 300 ml of 1 mol / l hydrochloric acid to 30 grams of attapulgite, stir at 50°C for 4 hours, centrifuge, then wash with deionized water until no chloride ion is detected with 0.1 mol / l silver nitrate solution Finally, centrifugal dehydration, drying, crushing.

[0049] The used attapulgite raw material and other techniques are the same as in Example 1. The average unit adsorption capacity and the average enzyme activity of lipase on the attapulgite in the resulting product are close to the results of Example 1.

Embodiment 3

[0051] Acid treatment of attapulgite: add 300 ml of 6mol / l hydrochloric acid to 30 grams of attapulgite, stir at 50°C for 0.5 hours, centrifuge, then wash with deionized water until no chloride ion is detected with 0.1mol / l silver nitrate solution Finally, centrifugal dehydration, drying, crushing.

[0052] The used attapulgite raw material and other techniques are the same as in Example 1. The average unit adsorption capacity and the average enzyme activity of lipase on the attapulgite in the resulting product are close to the results of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com