Flyback power converter

A power converter, a flyback technology, applied in the output power conversion device, the conversion of DC power input to DC power output, the conversion of AC power input to DC power output, etc., can solve the problem of high power consumption, flyback power The converter lacks regulation, easily destroys the transistor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

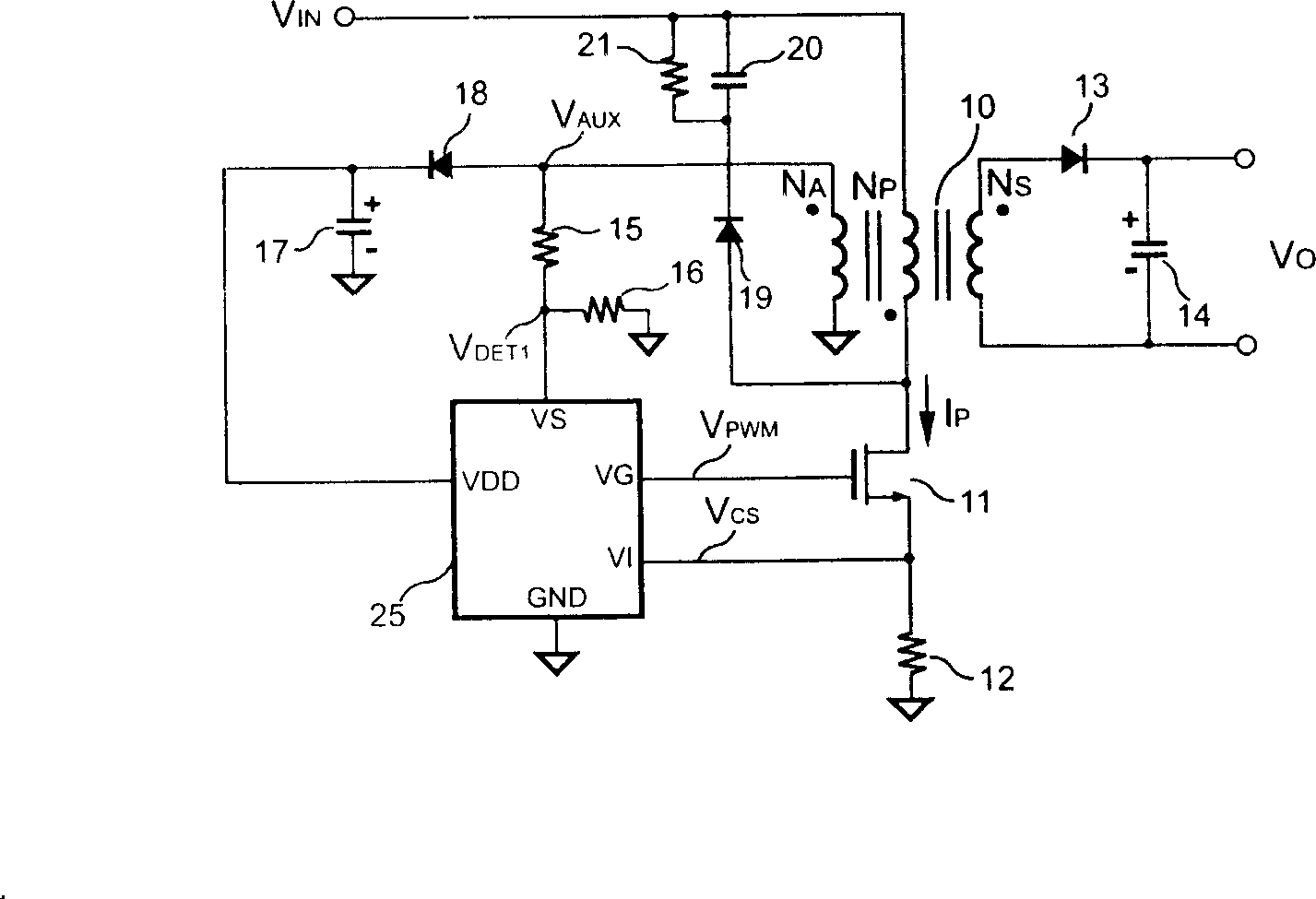

[0053] In order to enable the examiner to have a better understanding and understanding of the structural features and achieved effects of the present invention, I would like to provide a diagram of a better embodiment and a detailed description, as follows:

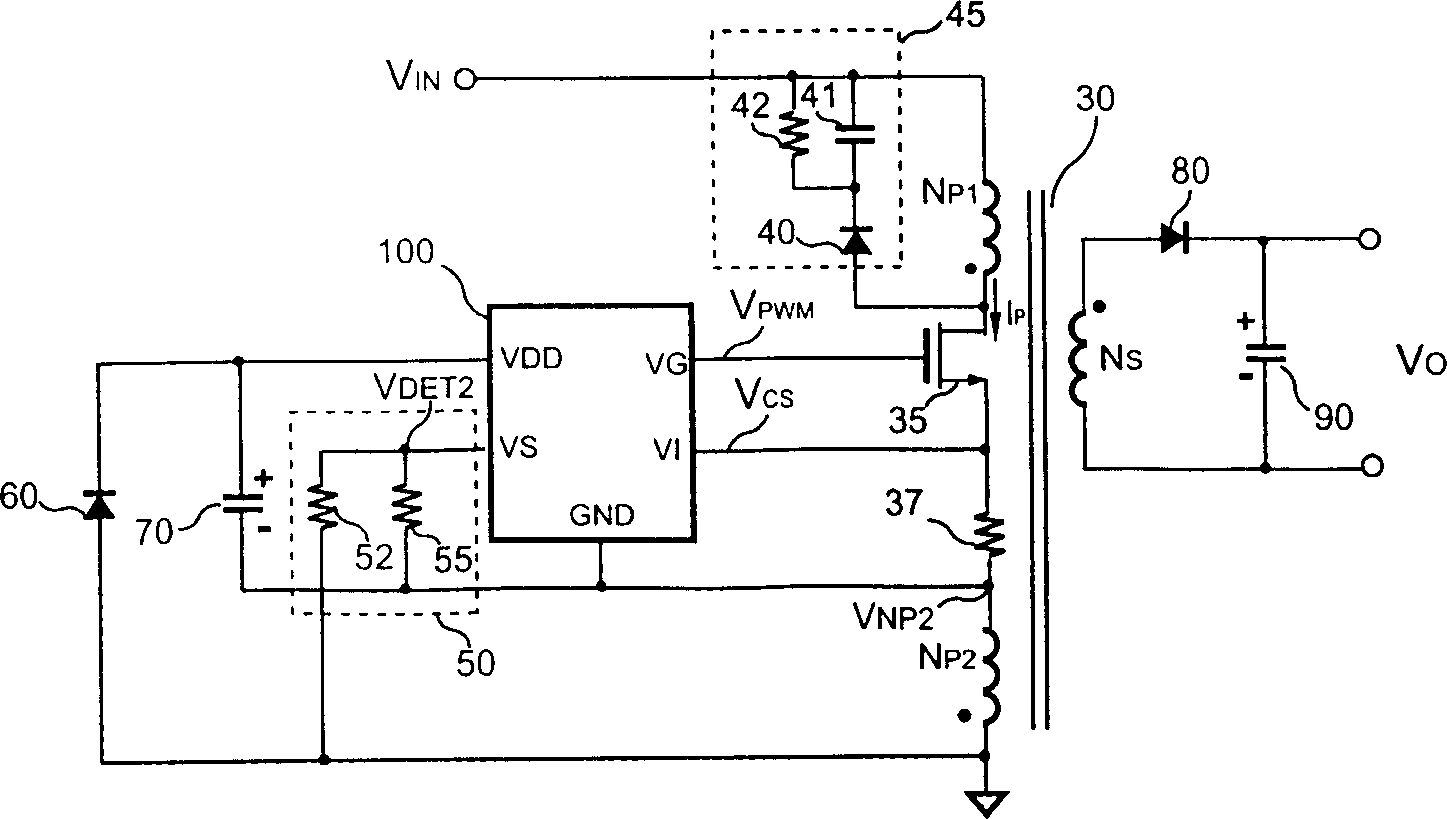

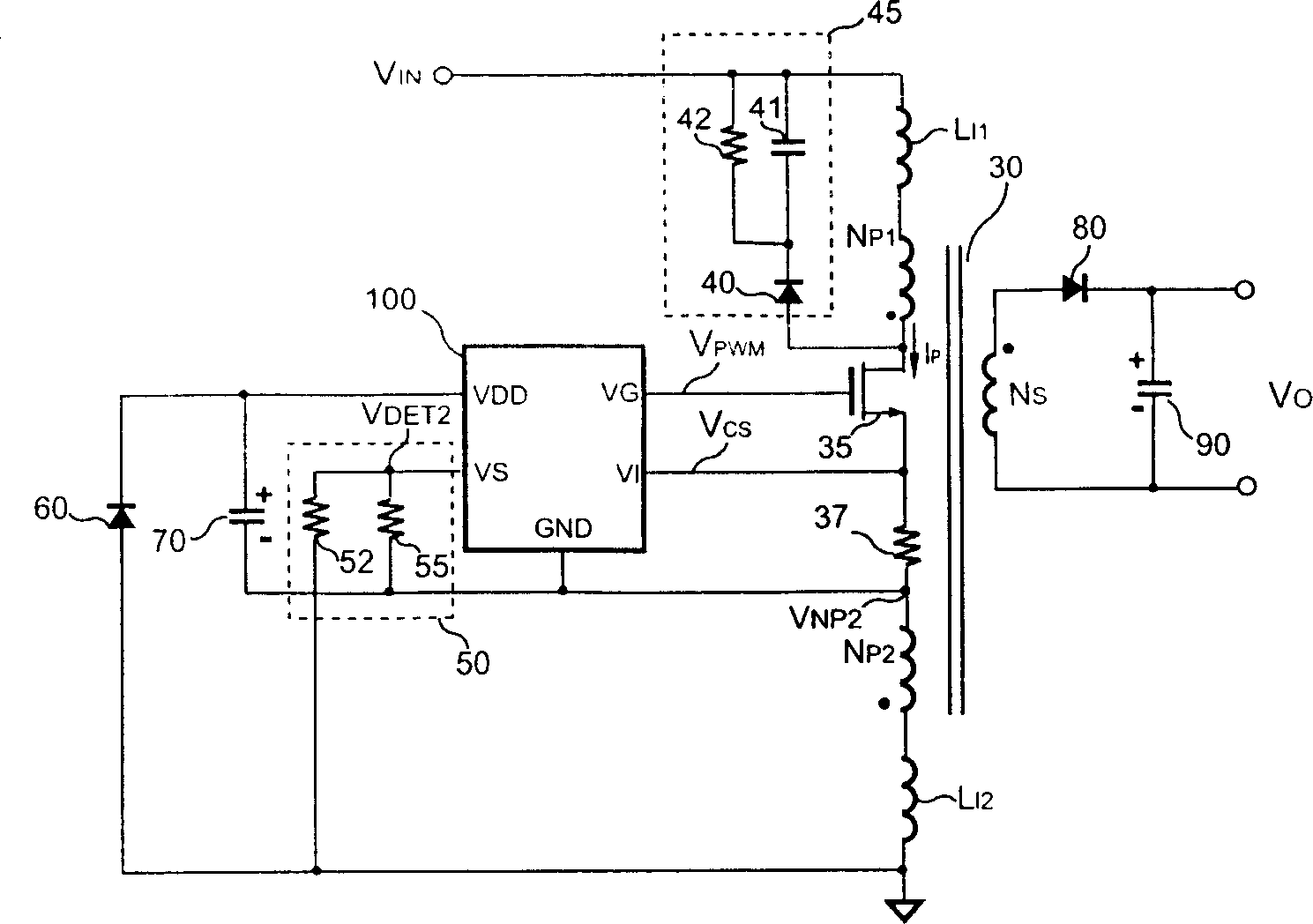

[0054] see figure 2 , is a circuit diagram of a flyback power converter according to a preferred embodiment of the present invention. As shown in the figure, the flyback power converter of the present invention includes a transformer 30 for storing energy and transferring the stored energy from a primary side of the transformer 30 to a secondary side of the transformer 30 . Wherein, the primary side of the transformer 30 is provided with a cut-first primary side winding N P1 with a second primary winding N P2 , and the secondary side of the transformer 30 is provided with a secondary side winding N S . The first primary side winding N P1 with the second primary winding N P2 Coupled to the power supply rail of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com