Biological extrusion screw and method for making same

A technology for extruding screws and manufacturing methods, applied in medical science, internal bone synthesis, fastening devices, etc., can solve the problems of strong stress shielding effect, local effusion reaction, cortical bone atrophy and loosening, etc., and achieve good mechanical properties. The effect of strength, easy installation and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

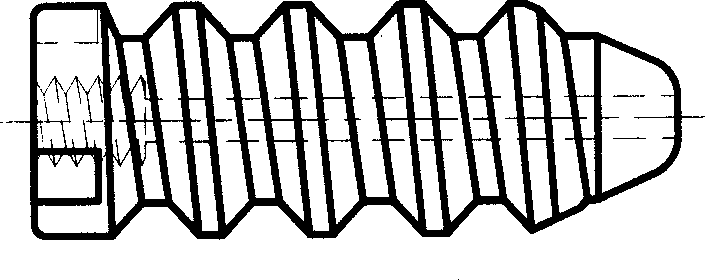

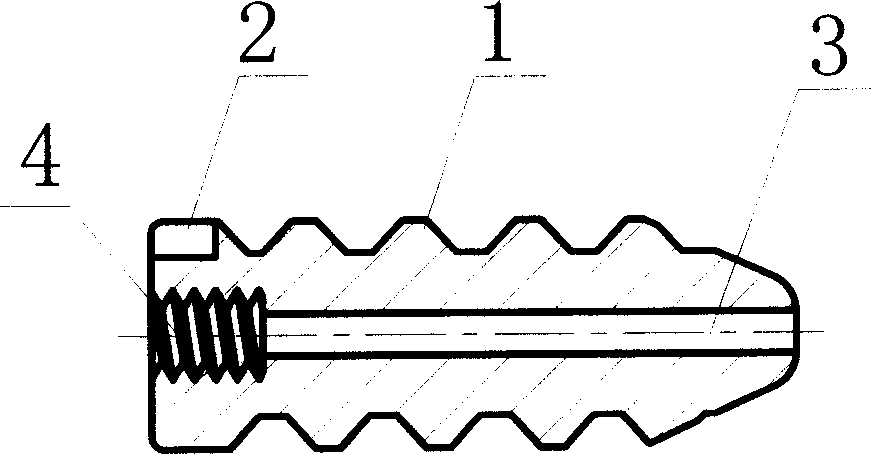

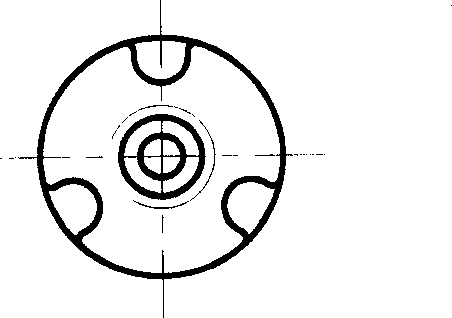

[0027] Embodiment 1: as figure 1 , figure 2 , image 3 As shown, the biological extrusion screw is a cylindrical threaded body 1 with a conical front end. There are three radial grooves 2 evenly distributed in the radial direction on the rear peripheral edge of the cylindrical threaded body 1. The radial grooves 2 are The axial depth is 5 mm, and the root of the groove is a radial notch in the shape of a circular arc. There is a cylindrical through hole 3 in the center of the cylindrical threaded body 1 , and an internal thread 4 is provided at the rear end entrance section of the cylindrical through hole 3 .

[0028]The screw processing method is carried out according to the method disclosed in Chinese patent 200510031414.1, using pigs as raw materials, and the processing steps are carried out in the order of seed selection, slaughter, bone extraction, processing and molding, degreasing, cleaning, packaging, and sterilization. The specific steps are: select pigs that have...

Embodiment 2

[0031] Embodiment 2: as figure 1 , figure 2 , Figure 4 As shown, the biological extrusion screw is a cylindrical threaded body 1 with a conical front end. There are two radial grooves 2 evenly distributed in the radial direction on the rear peripheral edge of the cylindrical threaded body 1. The radial grooves 2 are A radial notch with an axial depth of 6 mm and a square root. There is a cylindrical through hole 3 in the center of the cylindrical threaded body 1 , and an internal thread 4 is provided at the rear end entrance section of the cylindrical through hole 3 .

[0032] The processing method of the screw is carried out according to the method disclosed in Chinese patent 200510031414.1, using sheep as raw material, and the processing steps are carried out in the order of seed selection, slaughter, hanging detoxification, bone extraction, processing and molding, degreasing, cleaning, packaging, and sterilization. The specific steps are as follows: select slaughtered ...

Embodiment 3

[0033] Embodiment 3: as figure 1 , figure 2 , Figure 5 As shown, the biological extrusion screw is a cylindrical threaded body 1 with a conical front end. There are four radial grooves 2 evenly distributed in the radial direction on the peripheral edge of the rear end of the cylindrical threaded body 1. The radial grooves 2 are The axial depth is 4 mm, and the root of the groove is a radial notch in the shape of a circular arc. There is a cylindrical through hole 3 in the center of the cylindrical threaded body 1 , and an internal thread 4 is provided at the rear end entrance section of the cylindrical through hole 3 .

[0034] The processing method of the screw is carried out according to the method disclosed in Chinese patent 200510031414.1, using horses as raw materials, and the processing steps are as follows: selection, slaughter, suspension detoxification, bone extraction, mad cow disease pathogen detection, processing and molding, degreasing, cleaning, packaging, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com