Method for aotomatic controlling rise fall of electrodes in mine hot stove

An electrode lifting, submerged arc furnace technology, applied in the direction of electrical program control, computer control, general control system, etc., can solve the problems of inability to save electricity and low control accuracy, and achieve the effect of correcting deviations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

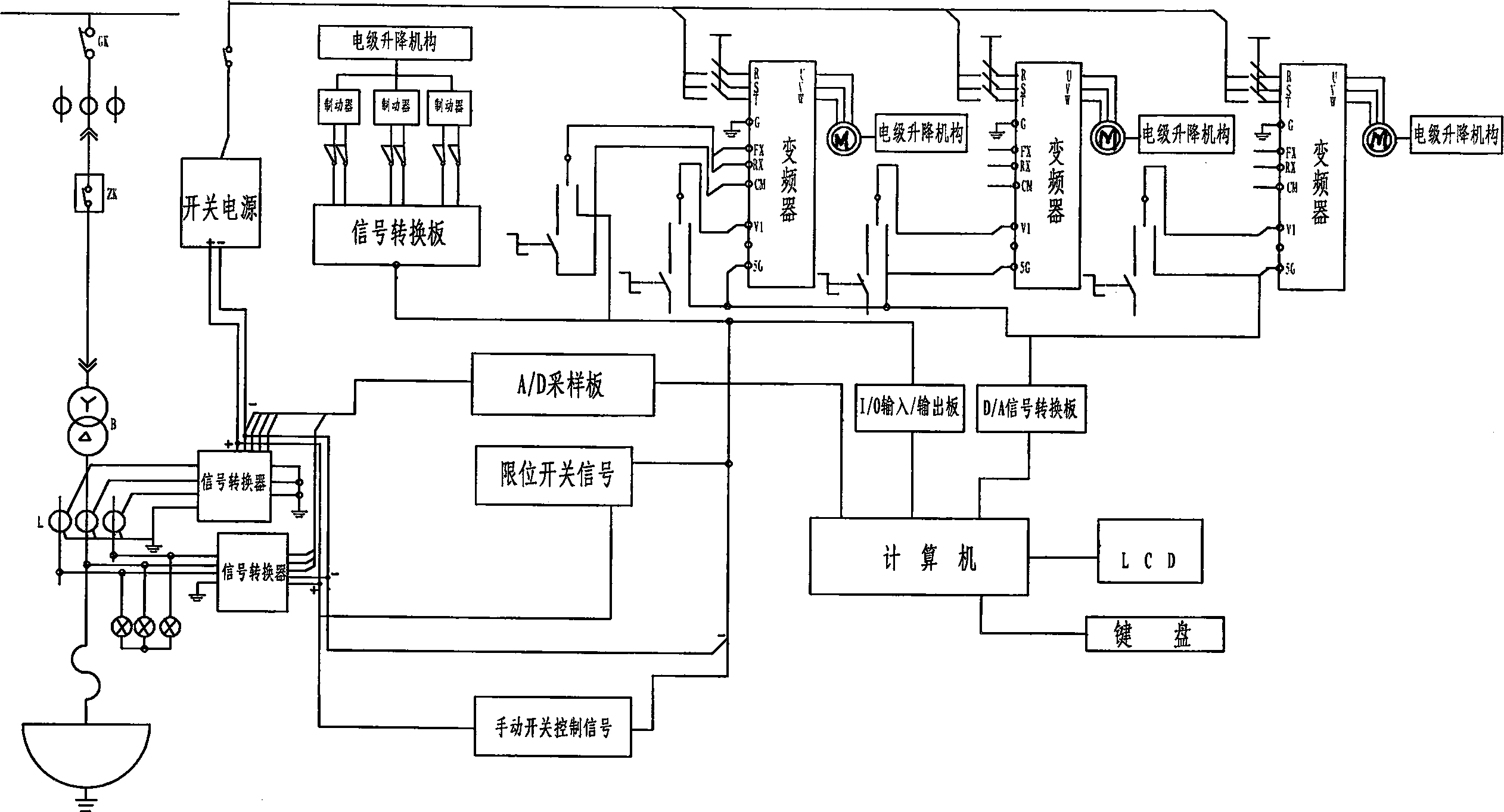

[0021] see figure 1 , a method for automatic control of submerged arc furnace electrode lifting. The 10KV three-phase alternating current of the power grid is connected to the primary of the submerged arc furnace transformer B through the isolation switch GK and the vacuum switch ZK. Phase alternating current enters the furnace to provide electric power through a large cross-section short network composed of large cross-section copper tubes or copper plates, soft copper cables, conductive devices and graphite electrodes.

[0022] The input signal of the present invention has: the primary or secondary of transformer B is equipped with current transformer L, the alternating current signal of output 0-5 ampere, is transformed into the direct current voltage of 0-5V (or 0-10V) through signal converter The analog signal is provided to the A / D sampling board; the other three-phase AC voltage signal is directly taken from the secondary outlet of the transformer B, which is a 0-500V A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com