Method for preparing superhard waterproof substances used for spectacle lens

A technology of spectacle lenses and power, applied in the direction of optical components, optics, instruments, etc., can solve problems such as unsatisfactory, unreached, scarred, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

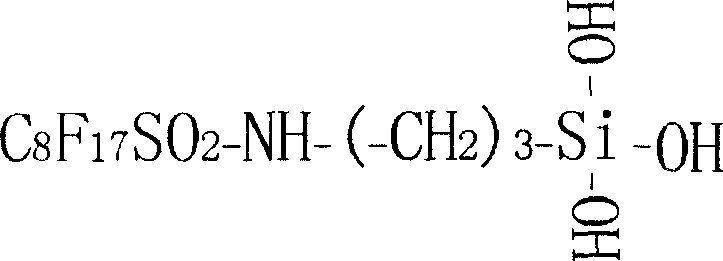

[0023] 1) Select N-perfluorooctylsulfonamidopropyltriethoxysilane as the main raw material, add 160ml of isopropanol, 18 grams of water, stir well;

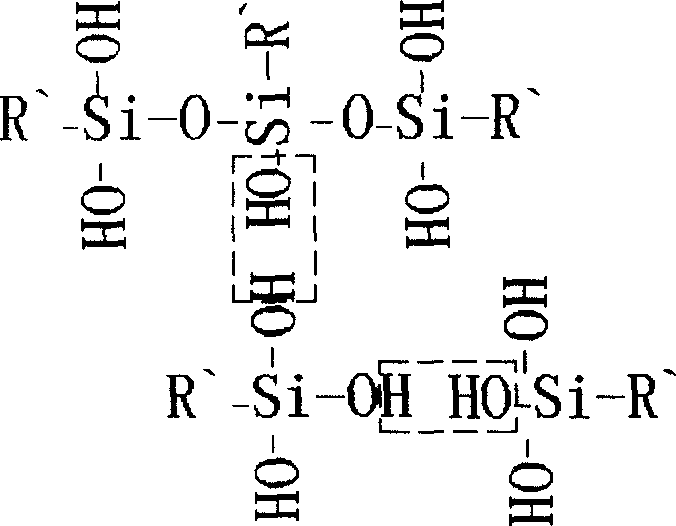

[0024] 2) Stir the solution, add 8 grams of concentrated nitric acid solution, heat to 55°C, and seal the reaction for 6 hours;

[0025] 3) Filtering and air-drying the reacted solution to obtain a light yellow amorphous crystal with a molecular weight of 20,000-40,000 and a boiling point of 300-400°C;

[0026] 4) Crush the crystals into 20 meshes or less, and mix in perfluorooctyl quaternary ammonium iodide in a ratio of 7:2 to prepare a powdery superhard waterproof coating material.

[0027] 5) Cut 0000# steel wool of 2-3cm and weigh about 0.3g, spread it into a piece with a width of 2cm, stack the two pieces of steel wool crosswise, weigh 0.3-0.5g of powder superhard waterproof coating material, wrap it Roll it into small balls, wrap a layer of 200-400 mesh stainless steel mesh or copper mesh, then put it into a mold, stamp ...

Embodiment 2

[0029] 1) Select N-perfluorooctylsulfonamidopropyltriethoxysilane as the main raw material, add 200ml of isopropanol, 20 grams of water, stir well;

[0030] 2) Stir the solution, add 10 grams of concentrated nitric acid solution, heat to 60°C, and seal the reaction for 7 hours;

[0031] 3) Filtering and air-drying the reacted solution to obtain a light yellow amorphous crystal with a molecular weight of 20,000-40,000 and a boiling point of 300-400°C;

[0032] 4) Crush the crystals into a size below 20 meshes, and mix in perfluorooctyl quaternary ammonium iodide in a ratio of 7:3 to prepare a powdery superhard waterproof coating material.

[0033] 5) Cut 0000# steel wool of 2-3cm and weigh about 0.3g, spread it into a piece with a width of 2cm, stack the two pieces of steel wool crosswise, weigh 0.3-0.5g of powder superhard waterproof coating material, wrap it Roll it into a small ball, wrap a layer of 200-400 mesh stainless steel mesh or copper mesh, then put it into a mold,...

Embodiment 3

[0035] 1) Select N-perfluorooctylsulfonamidopropyltriethoxysilane as the main raw material, add 240ml of isopropanol, 22 grams of water, stir well;

[0036] 2) Stir the solution, add 12 grams of acid solution, heat to 65°C, seal and react for 8 hours;

[0037] 3) Filtering and air-drying the reacted solution to obtain a light yellow amorphous crystal with a molecular weight of 20,000-40,000 and a boiling point of 300-400°C;

[0038] 4) Crush the crystals to a size below 20 meshes, and mix in perfluorooctyl quaternary ammonium iodide in a ratio of 7:4 to prepare a powdery superhard waterproof coating material.

[0039] 5) Cut 0000# steel wool of 2-3cm and weigh about 0.3g, spread it into a piece with a width of 2cm, stack the two pieces of steel wool crosswise, weigh 0.3-0.5g of powder superhard waterproof coating material, wrap it Roll it into small balls, wrap a layer of 200-400 mesh stainless steel mesh or copper mesh, then put it into a mold, stamp it into a special coppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com