Isocyanic acid esterified chloroethylene-vinyl acetate copolymer and its preparation method

A vinyl acetate, esterified vinyl chloride technology, applied in coatings, anti-corrosion coatings and other directions, can solve the problems of poor compatibility and adhesion, low activity, etc., to achieve strong product adaptability, simple synthesis process, good electrical properties. insulating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0015] (1) Catalyst preparation: 1 part of sodium hydroxide was weighed and dissolved in 80 parts of methanol, and left to stand overnight for use.

[0016] (2) Weigh 10 parts of vinyl chloride-vinyl acetate copolymer with a vinyl acetate molar content of 10.56%, place it in a reaction vessel, add 100 parts of acetone, put it into a constant temperature water bath and stir continuously, and when the temperature rises to 40°C, The vinyl chloride-vinyl acetate copolymer is fully dissolved, and the solution is uniform and transparent. At this time, 9.6 parts of sodium hydroxide methanol solution is added, and the reaction is carried out at a constant temperature of 40°C for 3 hours, and the vinyl chloride-vinyl acetate copolymer can be alcoholysed.

[0017] (3) Put the reactant solution in (2) above into a container, add methanol dropwise under magnetic stirring to precipitate the reactant, then wash and filter with methanol repeatedly three times. Vacuum drying at 40°C for 3 hou...

specific Embodiment approach 2

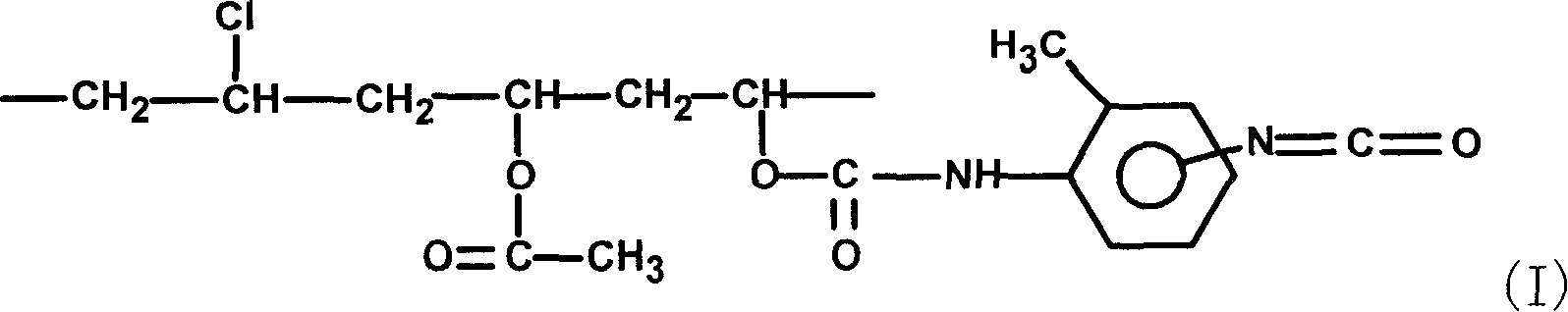

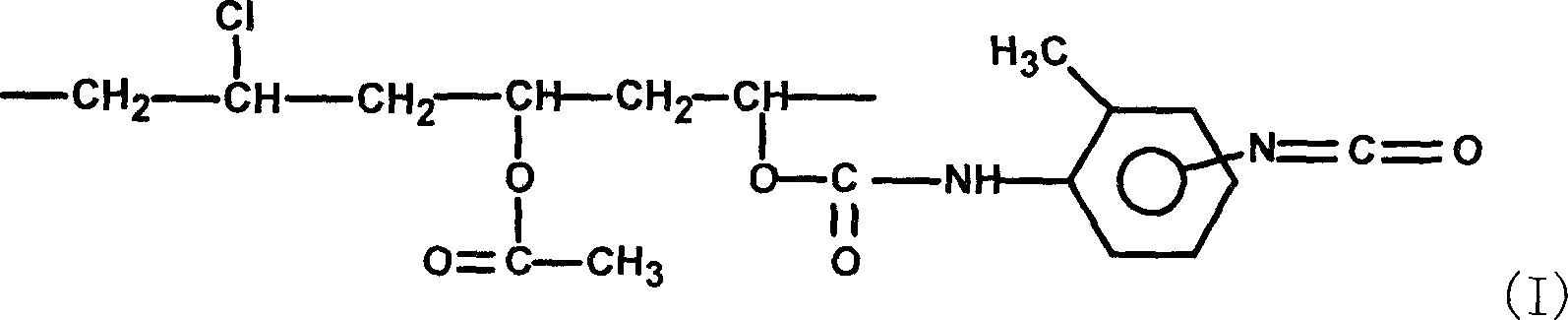

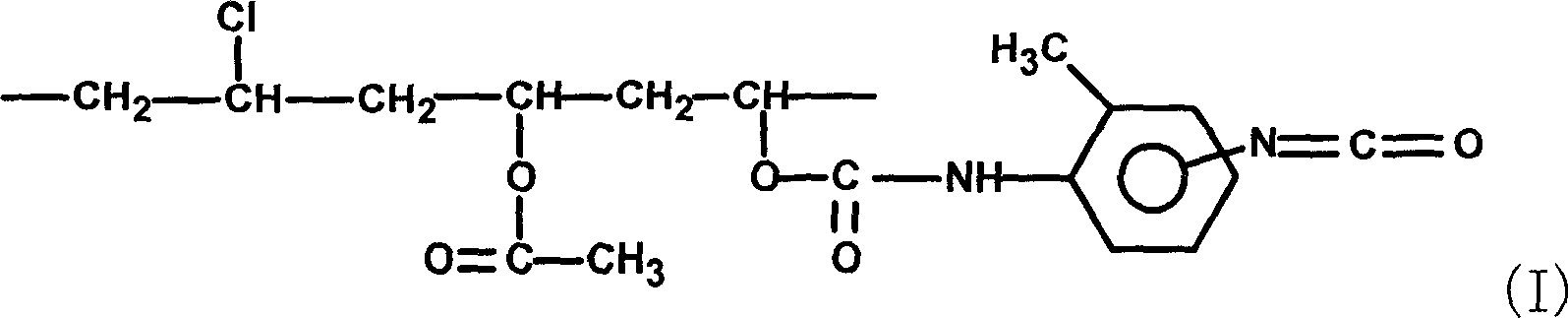

[0020] As in the method of Embodiment 1, 10 parts of gram vinyl chloride-vinyl acetate copolymer is dissolved in 100 parts of acetone, and when the temperature is raised to 40° C., 4.8 parts of methanolic sodium hydroxide solution is added dropwise to obtain a hydroxyl molar content of 6%. Hydroxylated vinyl chloride-vinyl acetate copolymer, precipitate and dry the copolymer; take 5 parts of the hydroxylated product and add 0.5 part of TDI-80 toluene diisocyanate at 85°C. An isocyanated vinyl chloride-vinyl acetate copolymer with a molar content of isocyanate groups of 6% was obtained. Its structural formula is as follows (I) formula:

[0021]

specific Embodiment approach 3

[0022] As in the method of embodiment 1, 10 parts of vinyl chloride-vinyl acetate copolymers with a vinyl acetate molar content of 28% are dissolved in 150 parts of acetone, and 16 parts of sodium hydroxide methanolic solution are added dropwise when the temperature is raised to 40°C To obtain a hydroxylated vinyl chloride-vinyl acetate copolymer with a hydroxyl molar content of 16%, the copolymer was precipitated and dried; 5 parts of the hydroxylated product were added to 1 part of TDI-100 toluene diisocyanate at 85°C. An isocyanated vinyl chloride-vinyl acetate copolymer with a molar content of isocyanate groups of 16% was obtained. Its structural formula is the same as the structural formula (I) of the above-mentioned specific embodiment 1 and specific embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com