Polytetrahydrofuran diol and its preparation and purification method

A technology of polytetrahydrofuran diol and tetrahydrofuran, which is applied in the field of polytetrahydrofuran diol and its preparation and purification, and can solve problems such as molecular weight deviation, molecular weight change, and misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0070] In the preparation method of the present invention, the tetrahydrofuran and the proton donor (preferably water) are completely mixed according to the proportion, continuously added to the polymerization reactor with a stirring device, and prepared under the action of the heteropolyacid catalyst. In the polytetrahydrofuran diol oligomer, the water is measured by weighing, and the accuracy requirement is greater than 0.1%.

[0071] The polymerization reactor is in a heterogeneous state, the upper layer is a solution containing polytetrahydrofuran diol and tetrahydrofuran, and the lower layer is a solution containing catalyst and tetrahydrofuran. Under the action of the stirring device, the upper and lower layers are fully mixed. The requirement for stirring the reactor is that the ratio of the displacement per minute to the effective volume of the polymerization reactor is in the range of 5-20, in other words, the number of cycles of the polymerization reactor is 5-20 tim...

Embodiment 1

[0110] Embodiment 1 (preparation of polytetrahydrofuran diol)

[0111] In this example, refined tetrahydrofuran was used, deionized water was used as the proton donor, and 12-tungstophosphoric acid (dried to 8 crystalline water) was used as the catalyst.

[0112] The refined tetrahydrofuran and deionized water are formulated into a homogeneous mixed solution at a molar ratio of 62.5:1, which is accurately measured to 0.1% by a balance. The solution is called tetrahydrofuran aqueous solution.

[0113] In addition, the refined tetrahydrofuran and the catalyst were formulated into a uniform mixed solution at a molar ratio of 42:1, which was called a catalyst solution.

[0114] The catalyst solution is added to the polymerization reactor, and then the tetrahydrofuran aqueous solution is continuously added into the reactor, and the mass ratio of the catalyst solution to the tetrahydrofuran aqueous solution in the reactor is 3:1. The polymerization reactor is equipped with a stirri...

Embodiment 2

[0122] Embodiment 2 (preparation of polytetrahydrofuran diol)

[0123] The preparation of polytetrahydrofuran diol was carried out in the same manner as in Example 1, except that the conversion rate of tetrahydrofuran was controlled at 29±0.5%.

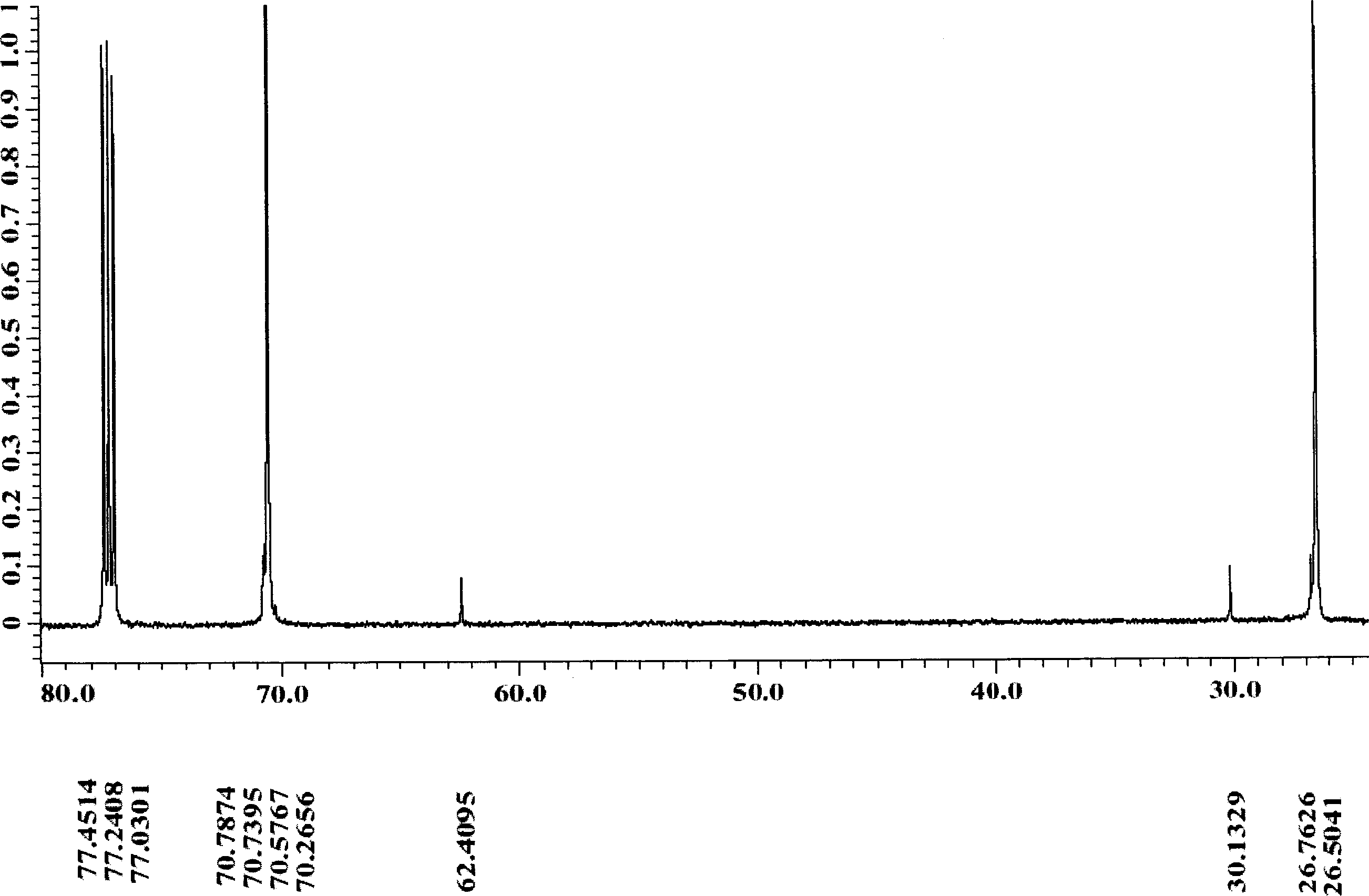

[0124] The polymer product of gained adopts the method identical with embodiment 1 to carry out characterization, confirms that its structure is:

[0125] HO(CH 2 ) 4 O n h

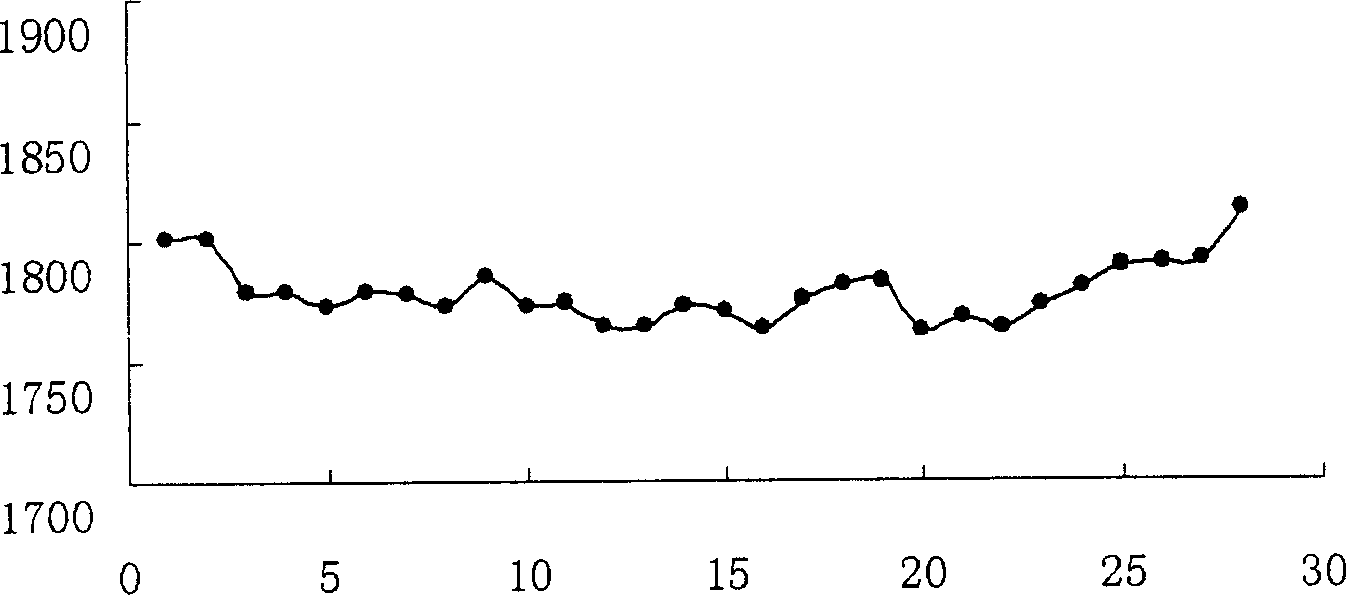

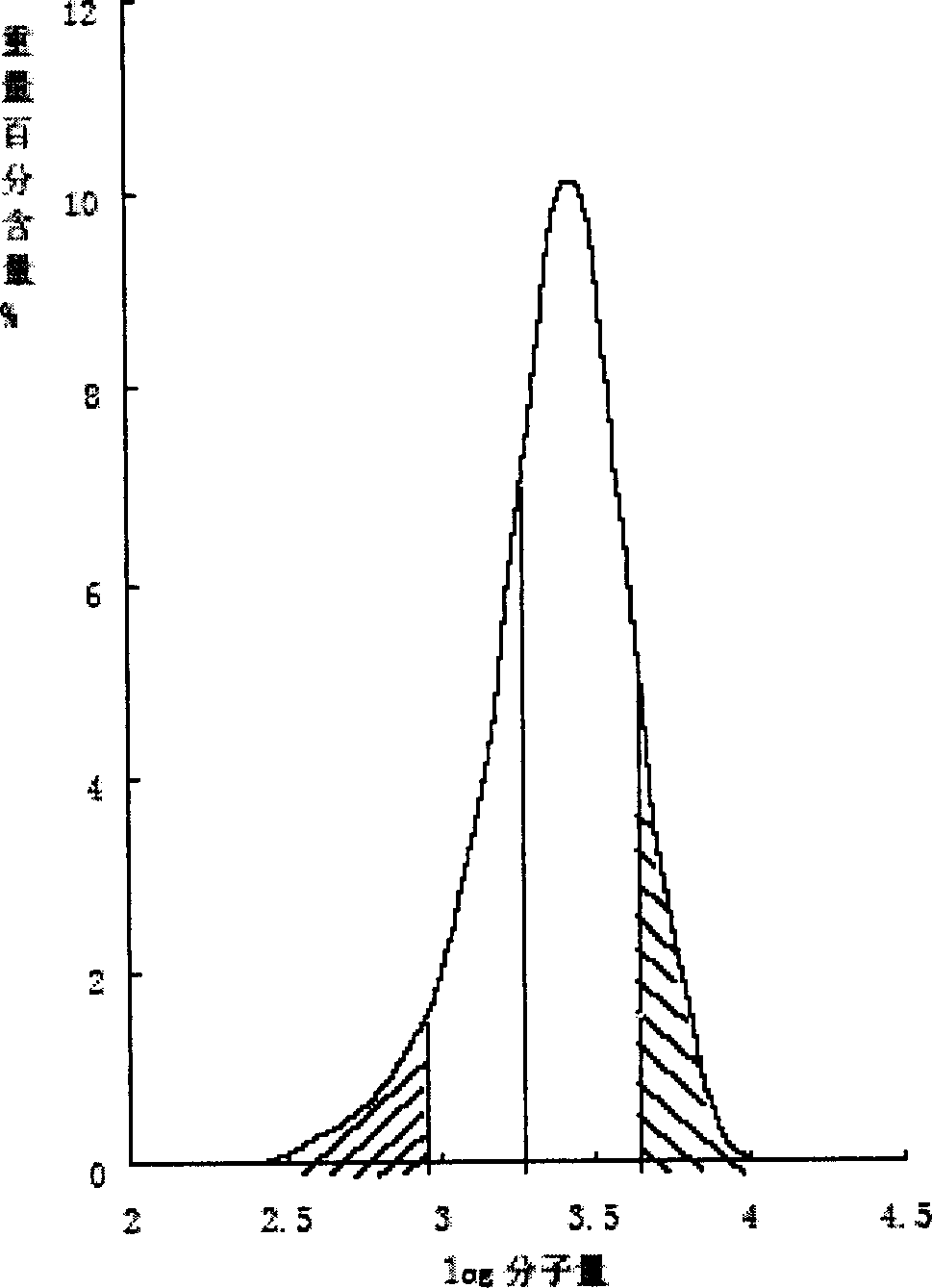

[0126] The number-average molecular weight-time relation of gained polytetrahydrofuran diol is monitored in the same manner as in Example 1, and it is found that the number-average molecular weight of the polytetrahydrofuran diol product is stably controlled within the scope of 2000 ± 50 Daltons .

[0127] The viscosity of the obtained polytetrahydrofuran diol is measured in the same manner as in Example 1, and the viscosity of the polytetrahydrofuran diol prepared in this embodiment is 560-600 centipoise.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com