Prepn of DL-alanine

A preparation process, alanine technology, is applied in the field of DL-alanine preparation process, which can solve the problems of large amount of three wastes, long operation cycle, and low treatment efficiency, and achieve easy quality control, pollution avoidance, and simplified The effect of steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

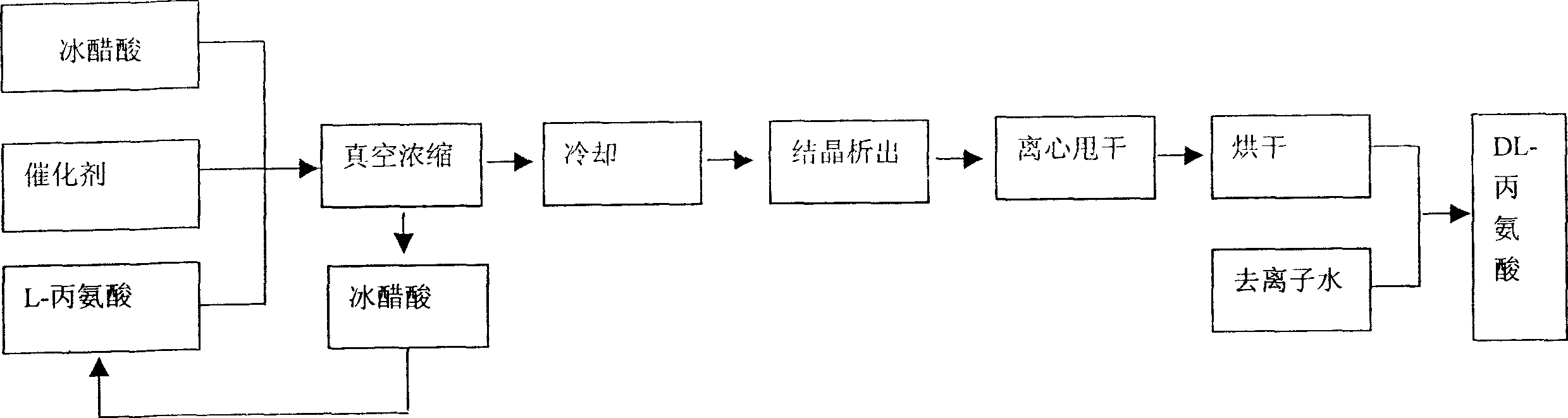

Image

Examples

Embodiment 1

[0016] Put 130 kilograms of L-alanine as raw material, 0.18 kilograms of salicylaldehyde as a catalyst and 1200 kilograms of glacial acetic acid solution into a reaction kettle and heat to dissolve and react at 80°C; keep the temperature at 100°C for evaporation and concentration, and pass The role of the catalyst breaks the hydrogen bond of the carbon atom in L-alanine and transfers it to obtain racemic DL-alanine; after cooling the mother liquor of racemic DL-alanine to 50°C, The DL-alanine supersaturated crystals containing impurities are precipitated. After the crystals are placed in a centrifuge and dried by centrifugation, they are placed in a double-cone dryer and heated to 120°C to dry to obtain the second crude product DL-alanine. Acid; add deionized water with activated carbon to the crude product DL-alanine for supersaturated recrystallization, put the crystals in a centrifuge again to dry them, and put them in a double-cone dryer and heat them to 120°C Dry at a tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com