Lithium-ion film cell negative pole and preparing method

A thin-film battery and lithium-ion technology, applied in the direction of electrode manufacturing, battery electrodes, active material electrodes, etc., to achieve the effects of facilitating penetration, enhancing connection force, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] First assemble the electrostatic spray deposition device used in the present invention: put one end of the 0.8 mm inner diameter silicone tube into a 250 ml conical flask containing the precursor solution, connect the other end to a needle with a pinhole inner diameter of 0.4 mm, and then fix the silicone tube In the groove of the flow tube of the peristaltic pump, the positive lead wire clamp of the DC high voltage generator with a control flow range of 0-50ml / h and a voltage range of 0-40000V is connected to the injection needle and keeps the needle tip vertically upward, directly above the needle tip 1 A thermocouple is placed horizontally at -4cm, the temperature control range is 0-800°C, and the negative pole of the DC high voltage generator is connected to the thermocouple.

[0022] Then prepare the precursor solution: then prepare the precursor solution: take 0.0255 grams of LiOAC·2H respectively 2 O and 0.6227 g Co(OAC) 2 .·4H 2 O (that is, the molar ratio of ...

Embodiment 2

[0029] Take 0.0255 g of LiOAC·2H respectively 2 O and 0.6227 g Co(OAC) 2 4H 2 O (i.e. the Li:Co molar ratio is 1:1), stirred and fully dissolved in 50mL carbitol, using the same operation steps as in Example 1, using copper foil as the substrate, heating the substrate to a temperature of 245°C and The electrode film was obtained after being kept at this temperature and deposited for 2 hours, and its performance was tested after being assembled into a battery.

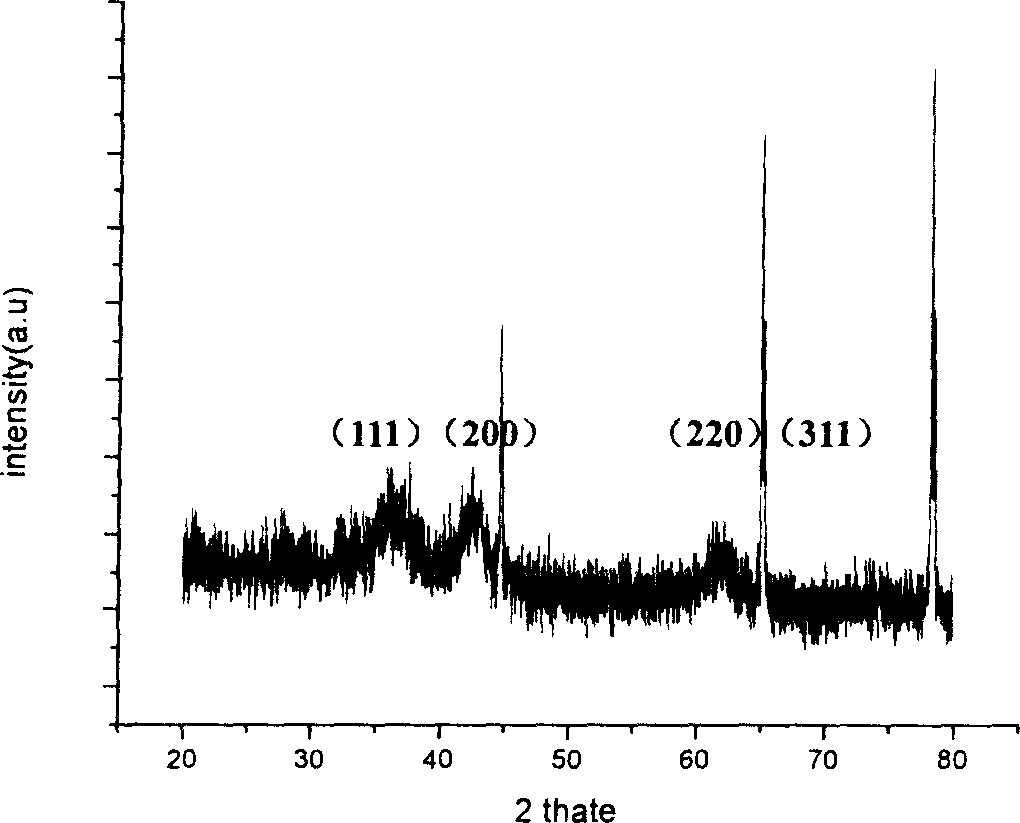

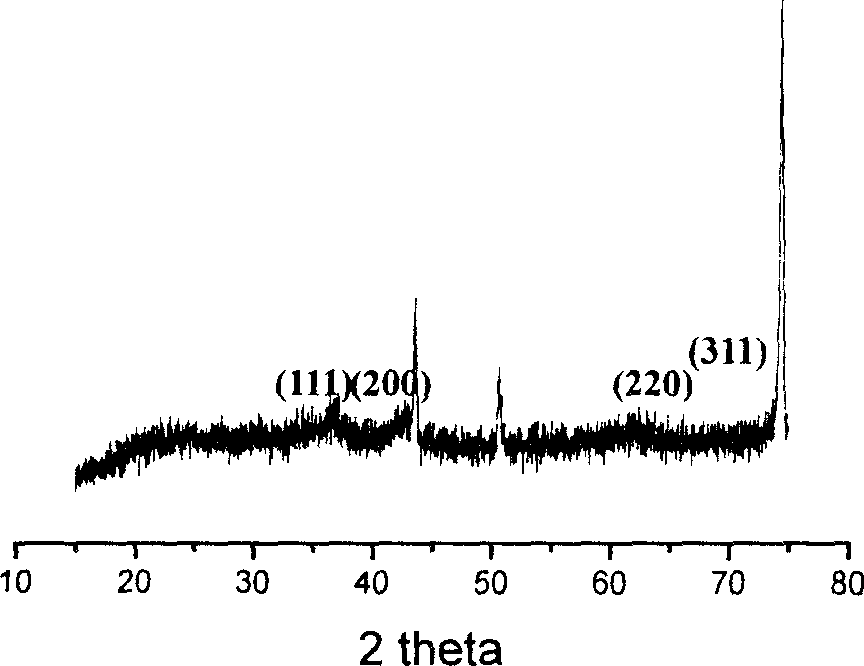

[0030] figure 2 It is the X-ray diffraction spectrogram of the incident copper target of the compound obtained in this example. In the figure, there are three sharp diffraction peaks at 44°, 52° and 75°, which are the diffraction peaks of the substrate, at 36°, 42.5°, There are four broad diffraction peaks around 61.5° and 74°, which are the (111), (200), (220) and (311) planes of CoO, respectively, and the relative intensity ratio of the peaks at 2θ of 42.5° and 36° is 1: 1.53; Know LiOAC 2H by embodiment 1 2 O d...

Embodiment 3

[0035] Take LiOAC·2H respectively 2 O and Co(OAC) 2 4H 2 O: Prepare five solutions with Li:Co ratios of 0.25:1, 0.5:1, 1:1, 2:1 and 4:1, the concentration of Co in each solution is 0.005 mol / L, and the solvent is 50 ml of carbo alcohol. Using the same steps as in Example 1, still choose foamed nickel as the substrate, keep the substrate at a constant temperature of 225 ° C, and deposit it for 2 hours respectively to obtain five chemical compositions of XLi 2 O.YCoO (X=0.125, Y=1), XLi 2 O.YCoO (X=0.25, Y=1), XLi 2 O·YCoO (X=0.5, Y=1), XLi 2 O·YCoO(X=1, Y=1) and XLi 2 The electrode film of O·YCoO (X=2, Y=1), the performance of which was tested after the obtained electrode film was assembled into a battery.

[0036] Figure 7 The capacity of the electrode film prepared for this example at a voltage range of 3.00-0.01 volts and a discharge rate of 1C. When Li:Co is 0.25:1, 0.5:1, 1:1, 2:1 and 4:1, the discharge capacity of the electrode film is 480mAh / g, 550mAh / g, 760mAh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com