Energy coversion and converter, generation and generator, seawater desalination and desalinator

A technology of energy conversion and seawater, which is applied in steam engine installations, energy waste water treatment, machines/engines, etc. It can solve the problems of reducing the temperature difference of seawater, long water intake pipes, and the inability to use seawater for desalination, etc., to achieve the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

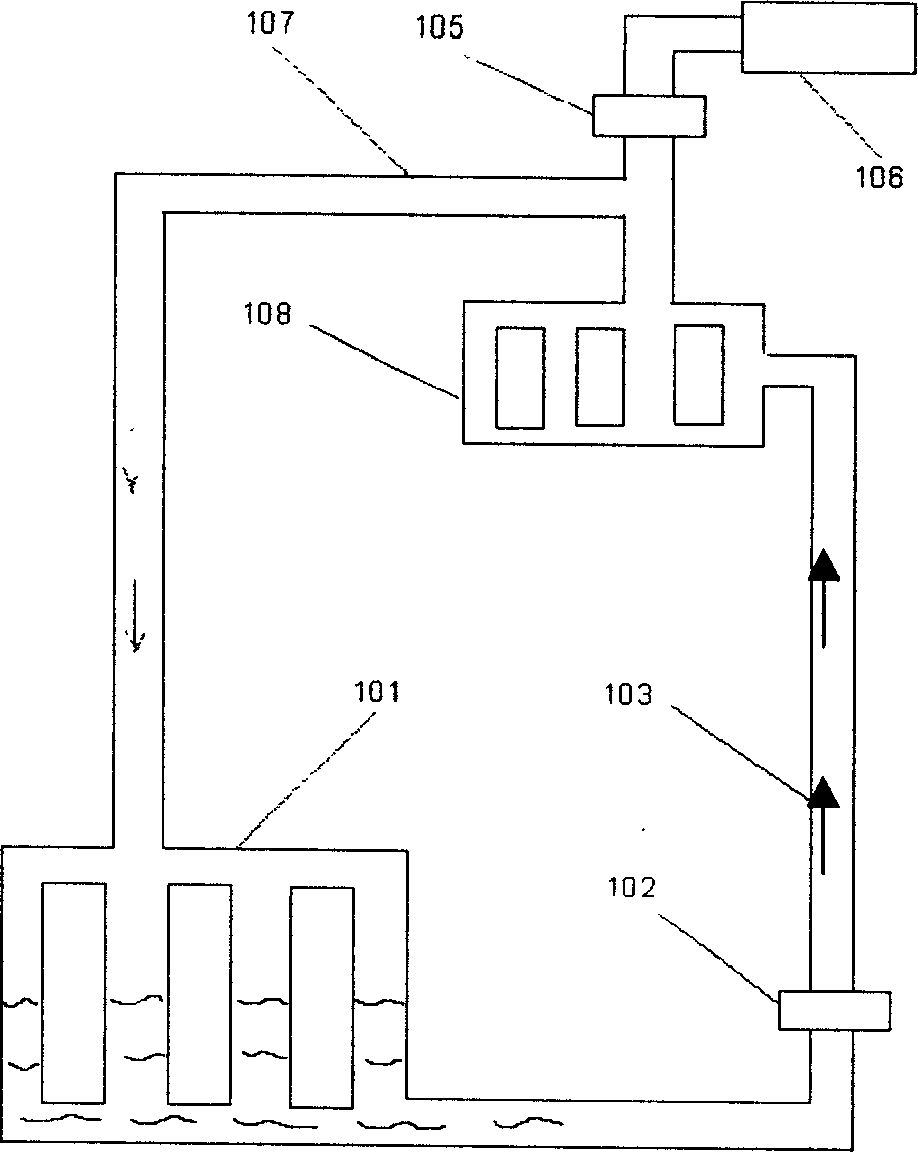

[0047] like figure 1 As shown: the energy conversion condensing system is composed of a cold exchanger 101 , a pump 102 , a communication pipeline 103 , a heat exchanger 108 , a vacuum valve 105 , a vacuum pump 106 and a communication pipeline 107 . The cold exchanger 101 and the heat exchanger 108 are made of thermal conductors and waterproof materials, the communication pipe 103 is made of heat-insulating, heat-preserving and waterproof materials, and the communication pipe 107 has no special requirements. The whole system is a closed circulation system, and the bottom of the cold exchanger 101 is pre-loaded with water or alcohol or a low-boiling point working medium. Parameters are different.) Cold exchanger 101 is fixed on the bottom of deep seabed or lake, well, river, reservoir, (the present invention explains with the working parameter of deep seabed, and the working principle of other lakes, wells, rivers, reservoirs is identical, Only the working parameters are diffe...

Embodiment 2

[0055] Figure 5 Among them, the solar box group 801 is a group of boxes made of thermal insulation material, the inner surface is made of black light-absorbing material (black plastic, etc.), and the top is sealed by double-layer vacuum glass (or high light-transmitting multi-layer inner inflatable plastic film) made. The inclination angle depends on the latitude of the area where it is located, and it is better to place it vertically with sunlight. Built-in high light-transmitting plastic water bag 802, the upper part of high light-transmitting plastic water bag 802 is composed of water inlet valve 806 and air release valve 805, and the lower part is composed of water outlet valve 803, so the structure can make sunlight pass through high light-transmitting plastic water bag 802 , directly irradiates the light-absorbing material at the bottom, and heats up from the bottom, the thermal efficiency can be increased by more than 20% compared with the vacuum tube solar water heat...

Embodiment 3

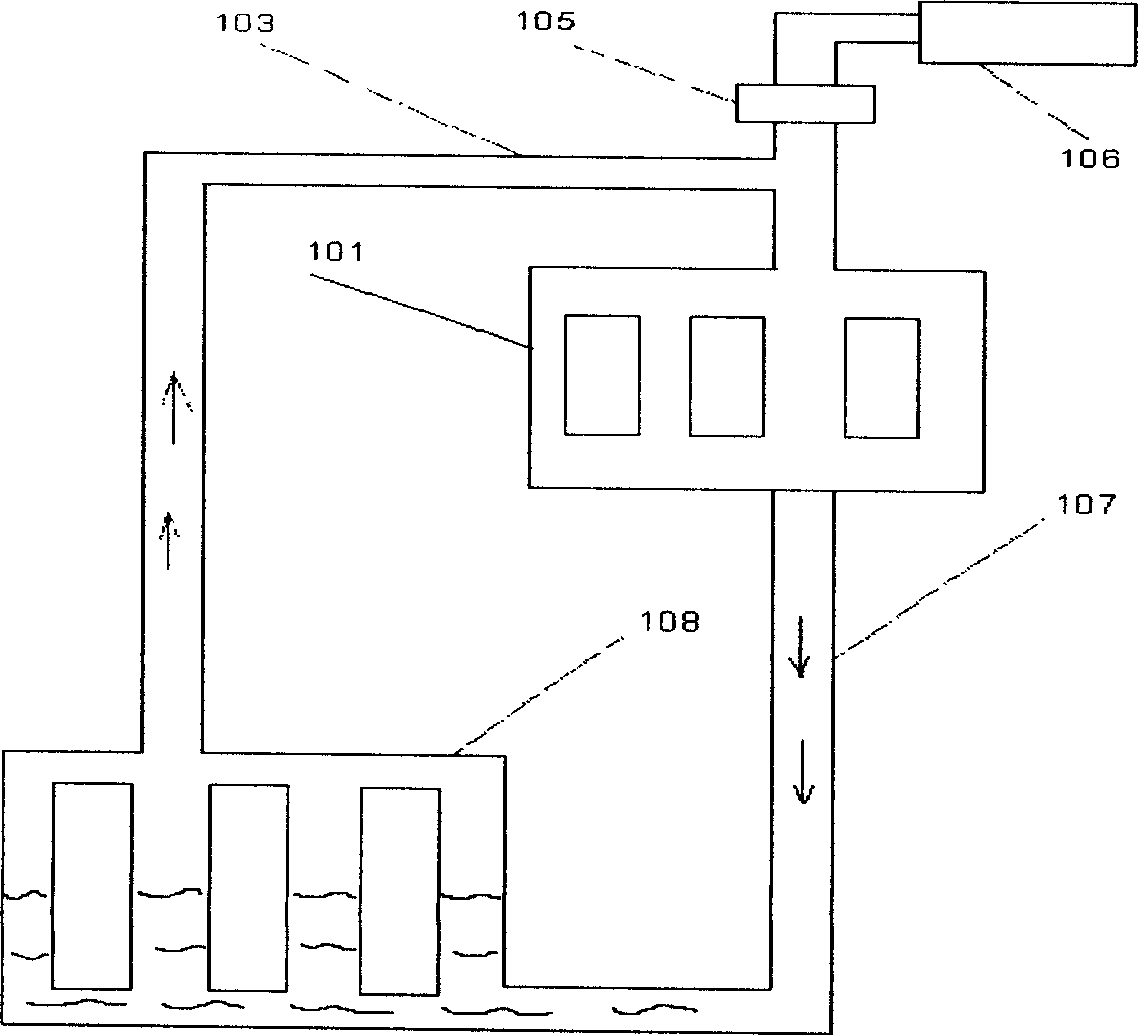

[0060] like figure 2 As shown: the energy conversion heat source system includes a cold exchanger 101, a communication pipeline 103, a heat exchanger 108, a vacuum valve 105, a vacuum pump 106, and a communication pipeline 107; the cold exchanger 101 and the heat exchanger 108 are composed of heat conductors 1. Made of waterproof material, the connecting pipe 103 is made of heat-insulating, heat-preserving, and waterproof materials, and the connecting pipe 107 has no special requirements. The cold exchanger 101 and the heat exchanger 108 are connected to form a circulation system through the communication pipeline 103 and the communication pipeline 107, and form a closed circulation system with the exhaust valve 105 and the vacuum pump 106.

[0061] The heat source system adopts an energy conversion system, which can effectively utilize geothermal resources; its working process is as follows: pre-load water (or alcohol or low boiling point working fluid) in the heat exchanger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com