Visible light hardened filling composite material for dental filling and its preparing method

A composite material and visible light technology, applied in dental preparations, dentistry, pharmaceutical formulations, etc., can solve the problems of low mechanical properties, reduced usability, unsatisfactory initiation rate, etc., and achieve the effect of no biotoxicity and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

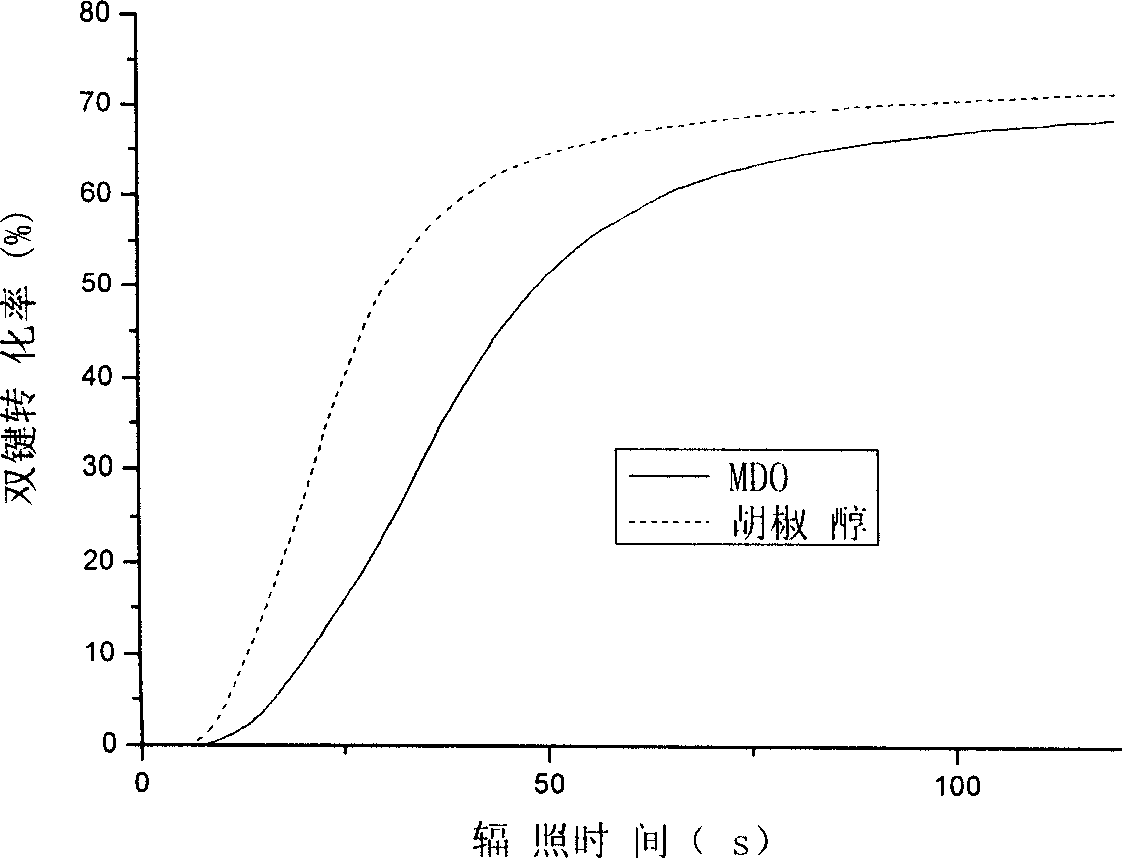

[0024] Dissolve 0.3771g photoinitiator aryl diketone (CQ) in 18.62g triethylene glycol dimethacrylate (TrEGDMA), mix with 56.85g bisphenol A glycidyl methacrylate (BISGMA) to prepare BISGMA / The proportioning ratio of TrEGDMA is 75wt%: 25wt%, and the organic resin system (I) with a CQ content of 0.5wt% is fully stirred to make the system evenly mixed, and placed in a dark room for subsequent use.

[0025] Take by weighing 3,4-methylenedioxybenzyl alcohol (piperol) shown in 0.1203g general formula (1) in a 25mL beaker, then add 12.0014g organic resin system (I) wherein, mix homogeneously, obtain Organic resin mixture containing 1.0 wt% piperonol. Then in this system, add the fumed silica filler AEROSIL R 711 (DEGUSSA company of Germany) 1.0116g (volume content is 40% of the mixture total amount) with the average particle size of 12 nanometers and the fumed silica with the average particle diameter of 7 nanometers Filler AEROSIL R 202 (Germany DEGUSSA company) 0.04864g (volume ...

example 2

[0027]Dissolve 0.9126g photoinitiator aryl diketone (CQ) in 36.50g tetraethylene glycol dimethacrylate (TTEGDMA), mix with 54.73g urethane dimethacrylate (UDMA) to prepare UDMA / The proportion of TTEGDMA is 60wt%: 40wt%, and the organic resin system (II) with a CQ content of 1.0wt%, is fully stirred to make the system evenly mixed, and placed in a dark room for later use.

[0028] Get 0.0105g of 3,4-methylenedioxybenzoic acid (piperic acid) shown in general formula (2) in a 25mL beaker, then add 10.2013g of organic resin system (II) to it, mix uniformly, and obtain 0.1 wt% piperic acid in organic resin mixture. Adding the fumed silica filler AEROSIL OX 50 (Germany DEGUSSA company) 0.4622g (volume content is 40% of the mixture total amount) and the fumed silica filler that the average particle size is 7 nanometers in this system then A 380 (China Guangzhou City Yirui New Material Co., Ltd.) (volume content is 20% of the mixture total amount) 0.2300g, fully stirred to make it m...

example 3

[0030] Dissolve 0.6678g of photoinitiator aromatic diketone (CQ) in 13.23g of 1,6-hexanediol dimethacrylate (HDDMA), mix with 53.50g of urethane dimethacrylate (UDMA) The organic resin system (III) with a UDMA / HDDMA ratio of 80wt%:20wt% and a CQ content of 0.1wt% was fully stirred to make the system evenly mixed, and placed in a dark room for later use.

[0031] Weigh 3,4-methylenedioxybenzoate methyl ester (methyl piperonate) shown in the general formula (7) of 0.1264g or 3,4-methylene dioxybenzoate shown in the general formula (3) Ethyl oxybenzoate (ethyl piperonate) in a 25mL beaker, then add 6.3327g of organic resin system (III) therein, fully stir to make the system mix uniformly, obtain an organic resin mixture containing 2.0wt% methyl piperonate . Then in this system, add the barium borosilicate glass (U.S. ESSCHEM company) 8.1045g (volume content is 30% of the mixture total amount) and the average particle size of 40 nanometers fumed silica filler AEROSIL OX 50 ( Ger...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com