Catalyst for simultaneously removing nitrogen oxide and CO in automobile exhaust

A technology for automobile exhaust and nitrogen oxides, applied in pollution control and fields, can solve the problem of high catalyst cost and achieve the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Using cerium nitrate as raw material, carrier CeO 2 Three methods were used to prepare:

[0025] (1)Ce(NO 3 ) 3 ·6H 2 O was calcined in a muffle furnace at 600 °C for 4 hours, and the obtained sample was named CeO 2 (1). (2) Preparation of cerium oxide by ammonia precipitation: take a certain amount of Ce(NO 3 ) 3 ·6H 2 O is made into a 0.05M solution and added to a 500ml round-bottomed flask, and at room temperature, in the constantly stirring solution, dropwise adding ammoniacal liquor with a concentration of 26 to 28wt.% to PH=10, reacted at room temperature for 10 hours, filtered, Wash until pH2 (2).

[0026] (3) Preparation of cerium oxide by uniform precipitation method: we use different molar concentration ratios of Ce(NO 3 ) 3 ·6H 2 O and urea aqueous solution as raw materials to prepare CeO 2 (where Ce(NO 3 ) 3 ·6H 2 O solution is selected as 0.05M), and finally optimizes its molar concentration ratio to be the best when it is 1:6. The preparati...

Embodiment 2

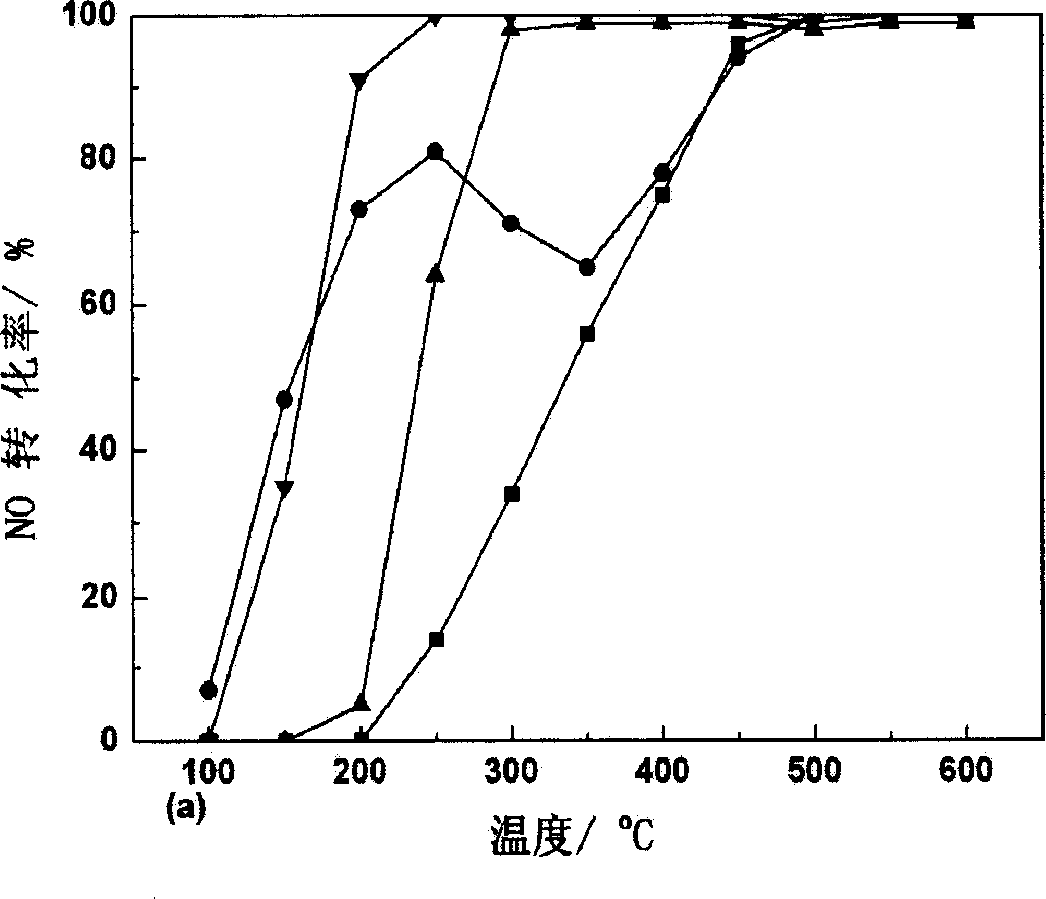

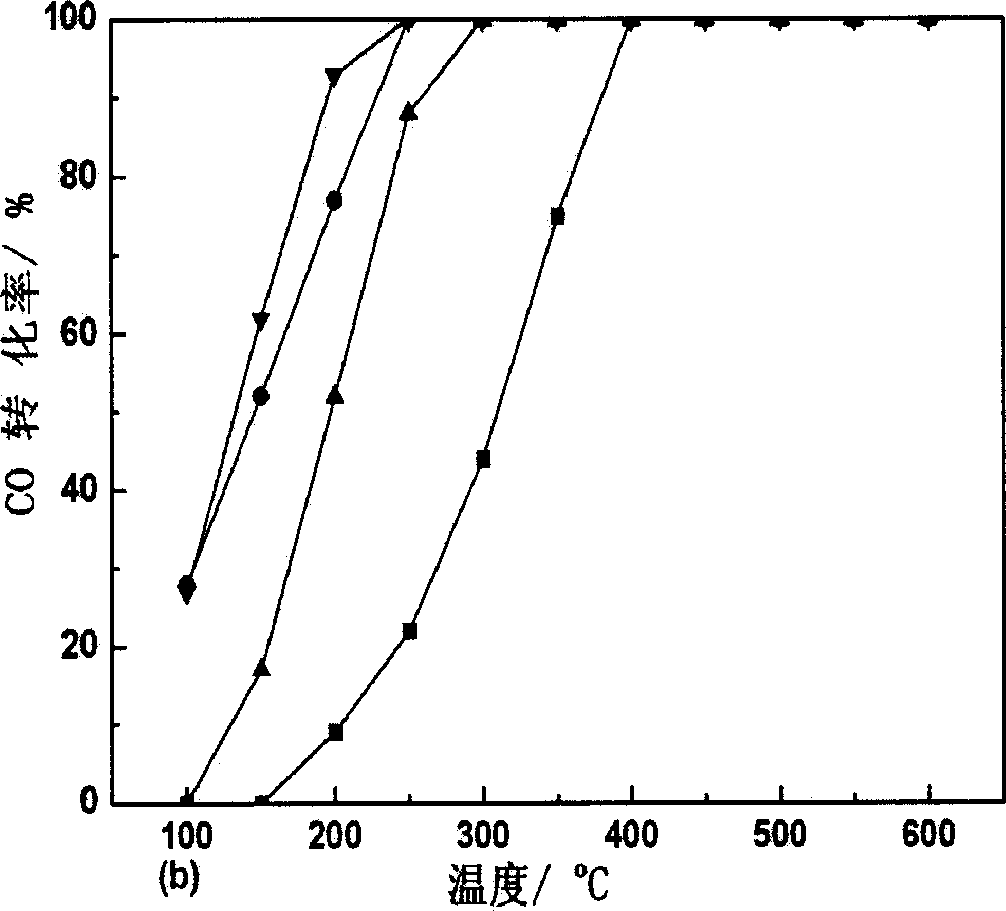

[0031] In Example 1 4wt%Ag / CeO 2 On the basis of introducing 0.4wt% Co in the same way, the resulting 4%Ag-0.4%Co / CeO 2 The activity of the catalyst and 4%Ag / CeO 2 and 0.4% Co / CeO 2 Catalyst activity comparison results are shown in the attached figure 1 And attached figure 2 (reaction conditions such as example 1).

Embodiment 3

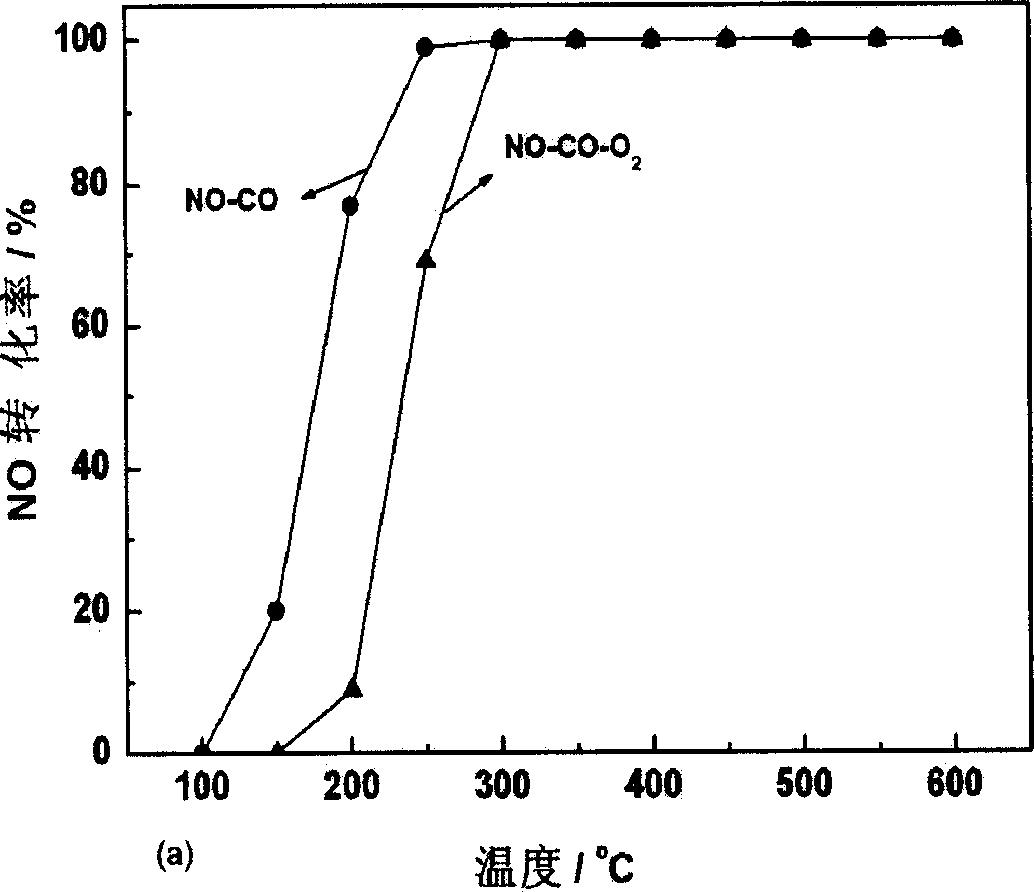

[0033] Get the 4%Ag-0.4%Co / CeO prepared in example 2 2 Catalyst 100mg is packed in the atmospheric pressure miniature fixed-bed reactor. Pretreatment at 500°C for 1 hour in He flow, and then lower the temperature to below 100°C. Respectively feed reaction gas 2500ppm NO+2500ppm CO+He and oxygen-containing reaction gas 2500ppm NO+5000ppm O 2 +12500ppm CO+He, flow rate 75ml / min, activity comparison results are shown in the attachment image 3 And attached Figure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com