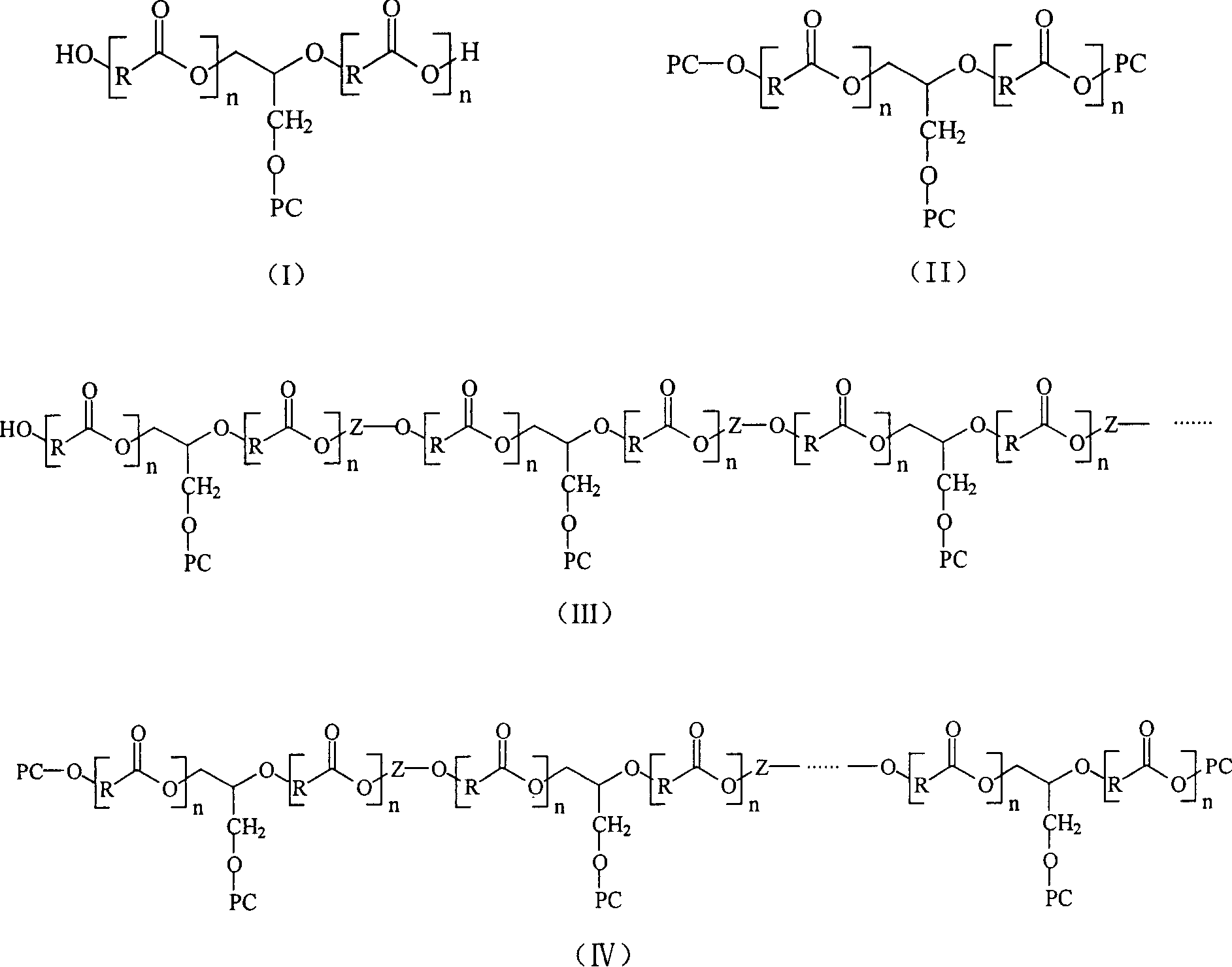

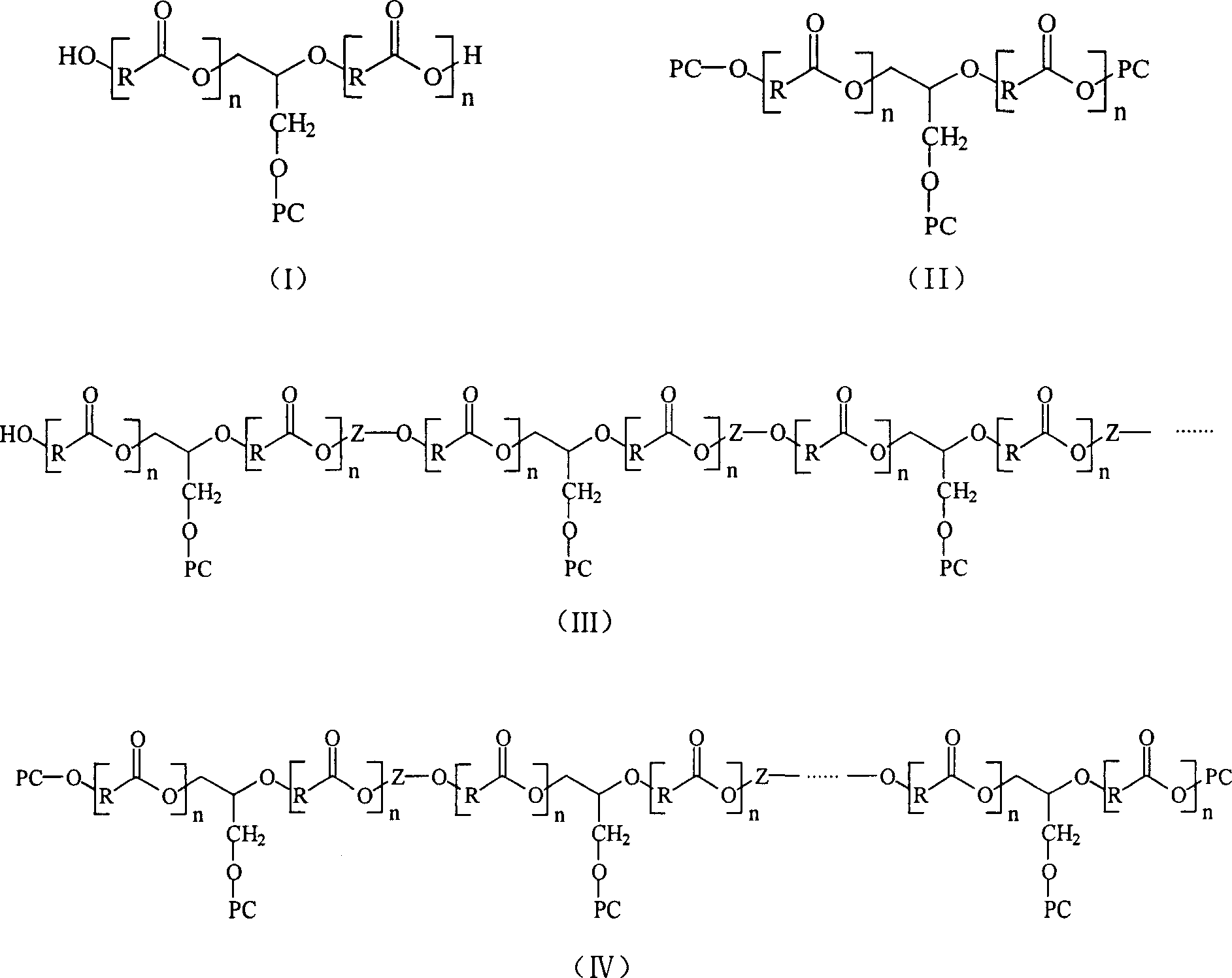

Biodegradable polyester containing phosphatidylcholine group and its preparation method

A technology for biodegrading polyester and phosphatidylcholine groups, which can be used in medical preparations, pharmaceutical formulations, medical science and other directions of non-active ingredients, and can solve the problem of limited number of phosphatidylcholine groups, limited contribution, and biocompatibility. It is easy to control the process, the method is simple, and the selection range is large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032]Mix 0.01 part of glycerol phosphatidylcholine with 10 parts of recrystallized and purified lactide, dry it, then add 1% metal zinc powder catalyst based on the mass of lactide and mix it under vacuum at 100mmHg and temperature 50℃ Drying at low temperature for 24 hours, sealing the tube under vacuum and reacting at 150° C. for 20 hours to obtain the biodegradable polyester (I) with single side chain containing phosphatidylcholine group which can be used directly.

Embodiment 2

[0034] Mix 1 part of glycerol phosphatidylcholine with 10 parts of recrystallized and purified caprolactone, dry, then add 0.01% stannous octoate catalyst based on the mass of caprolactone, mix, and dry at room temperature under a vacuum of 10 mmHg After 24 hours, vacuum seal the tube and react at 100° C. for 120 hours to obtain a biodegradable polyester (I) with a single side chain containing a phosphatidylcholine group that can be used directly.

Embodiment 3

[0036] Mix 0.01 part of glycerol phosphatidylcholine with 10 parts of recrystallized and purified lactide, dry them, and then add 5% aluminum isopropoxide catalyst based on lactide mass to mix. Dry at 100°C for 1 hour, seal the tube in vacuum and react at 180°C for 1 hour, dissolve the product in dichloromethane, precipitate out with anhydrous ether, and dry in vacuum to obtain a purified single side chain containing phosphatidylcholine group biodegradable polyester (I).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com