Preparation method of iron oxide pigment

An iron oxide pigment and slurry technology, applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve the problems of difficult source of surface treatment agent, poor dispersibility and suspension, fast settling speed, etc. Application cost, particle size reduction, effect of slower settling velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 0.8 kg of sodium silicate, 0.3 kg of butyl titanate and 0.5 kg of polyoxyethylene 6 sorbitan monolaurate were added to 100 kg of slurry with an iron oxide content of 60 wt%, stirred for 1 hour, and dried to contain The amount of water is less than 1wt%, crushed to obtain a dry material;

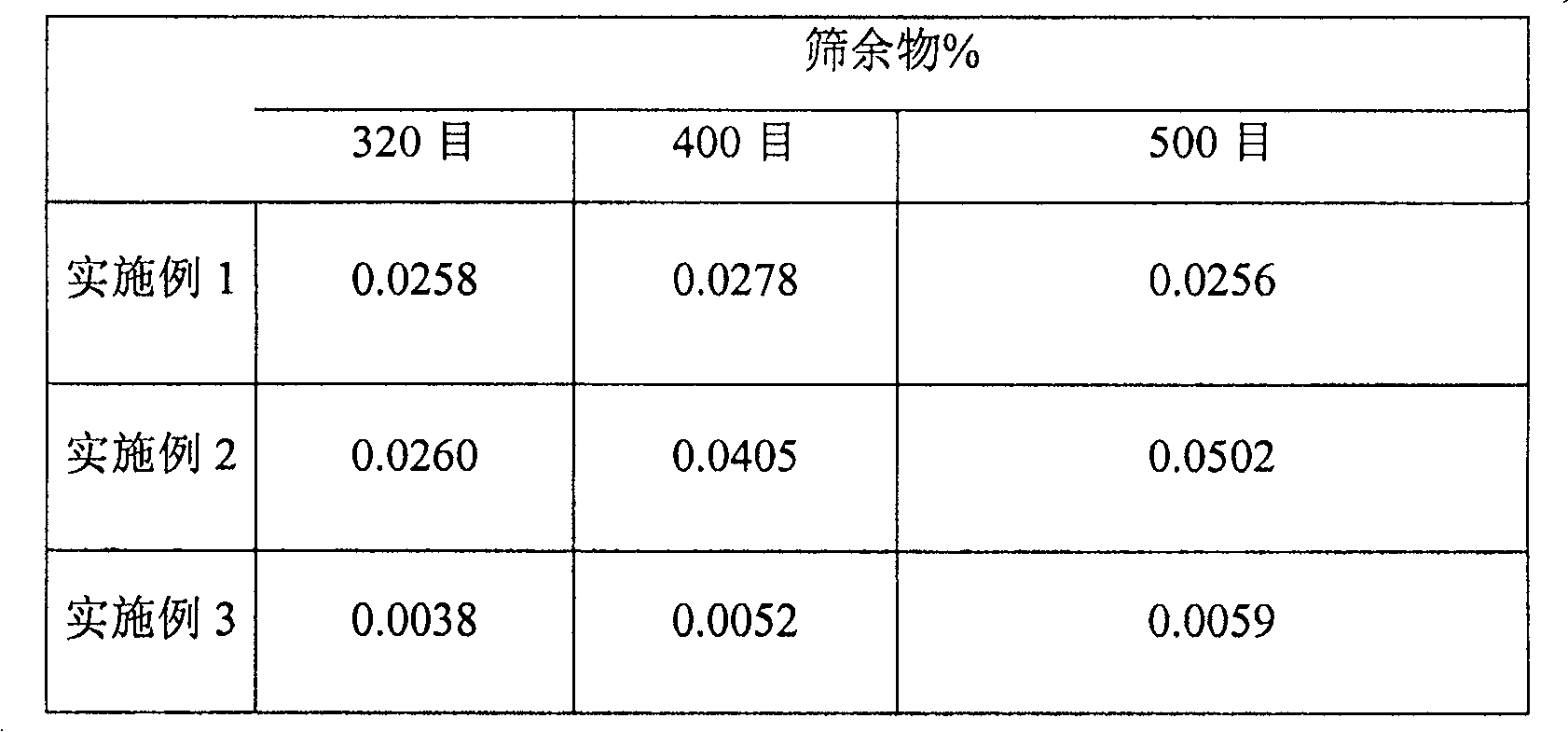

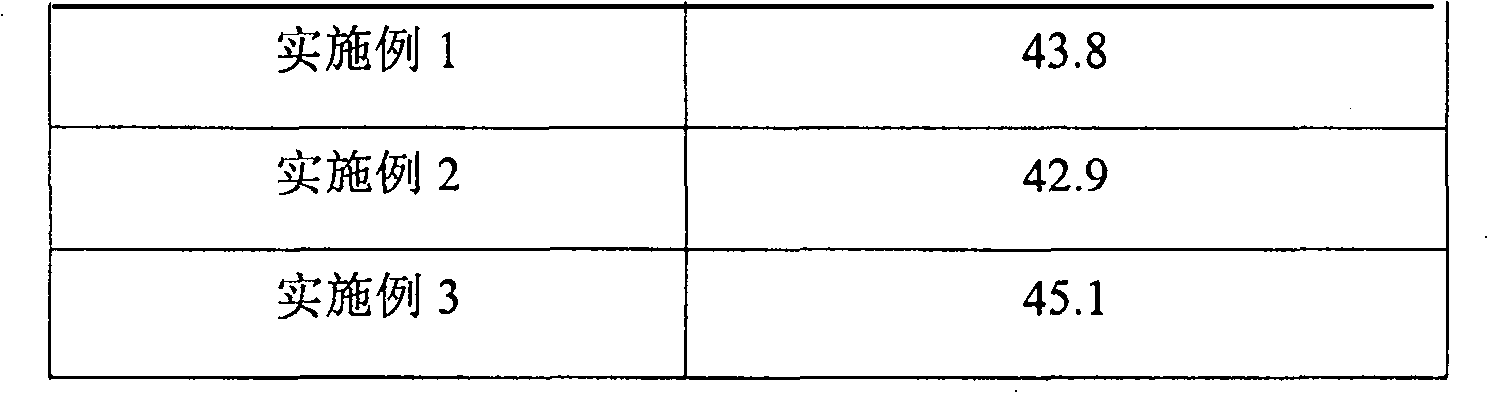

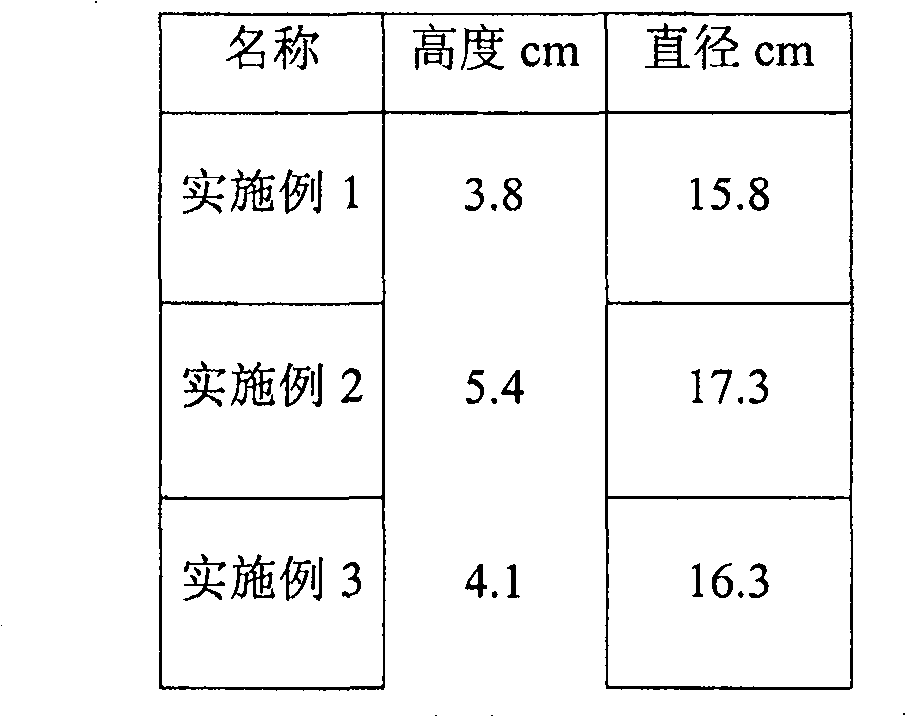

[0022] Add 0.4 kg of propylene glycol and 0.4 kg of butanediol into 100 kg of the above-mentioned powder, and stir evenly to obtain the iron oxide pigment of the present invention. The test results are shown in Table 1.

Embodiment 2

[0024] 0.5 kg of sodium silicate, 0.1 kg of butyl titanate and 0.3 kg of Tween 60 were added to 100 kg of slurry with an iron oxide content of 30 wt%, stirred for 1 hour, dried until the water content was less than 1 wt%, crushed to obtain dry material;

[0025] Add 0.3 kg of propylene glycol and 0.3 kg of butanediol into 100 kg of the above-mentioned powder, and stir evenly to obtain the iron oxide pigment of the present invention. The test results are shown in Table 1.

Embodiment 3

[0027] Add 0.5 kg of sodium silicate, 0.5 kg of butyl titanate, 0.4 kg of polyoxyethylene castor oil diglyceride and 0.4 kg of caprylic capric acid macrogolglyceride to 100 kg of a slurry with an iron oxide content of 30 wt%. , stirred for 1 hour, dried until the water content was less than 1wt%, and pulverized to obtain a dry material;

[0028] Add 0.3 kg of propylene glycol and 0.5 kg of butanediol into 100 kg of the above-mentioned powder, and stir evenly to obtain the iron oxide pigment of the present invention. The test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com