Production method of konjak mannose using cellulase

A technology of cellulase and mannan oligosaccharides, which is applied in the field of microbial enzymatic hydrolysis engineering, can solve the problems of too large molecular chain, which is not conducive to the activation and improvement of animal immunity and the improvement of human micro-ecological environment, and achieves simple enzymatic hydrolysis process, The effect of low cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

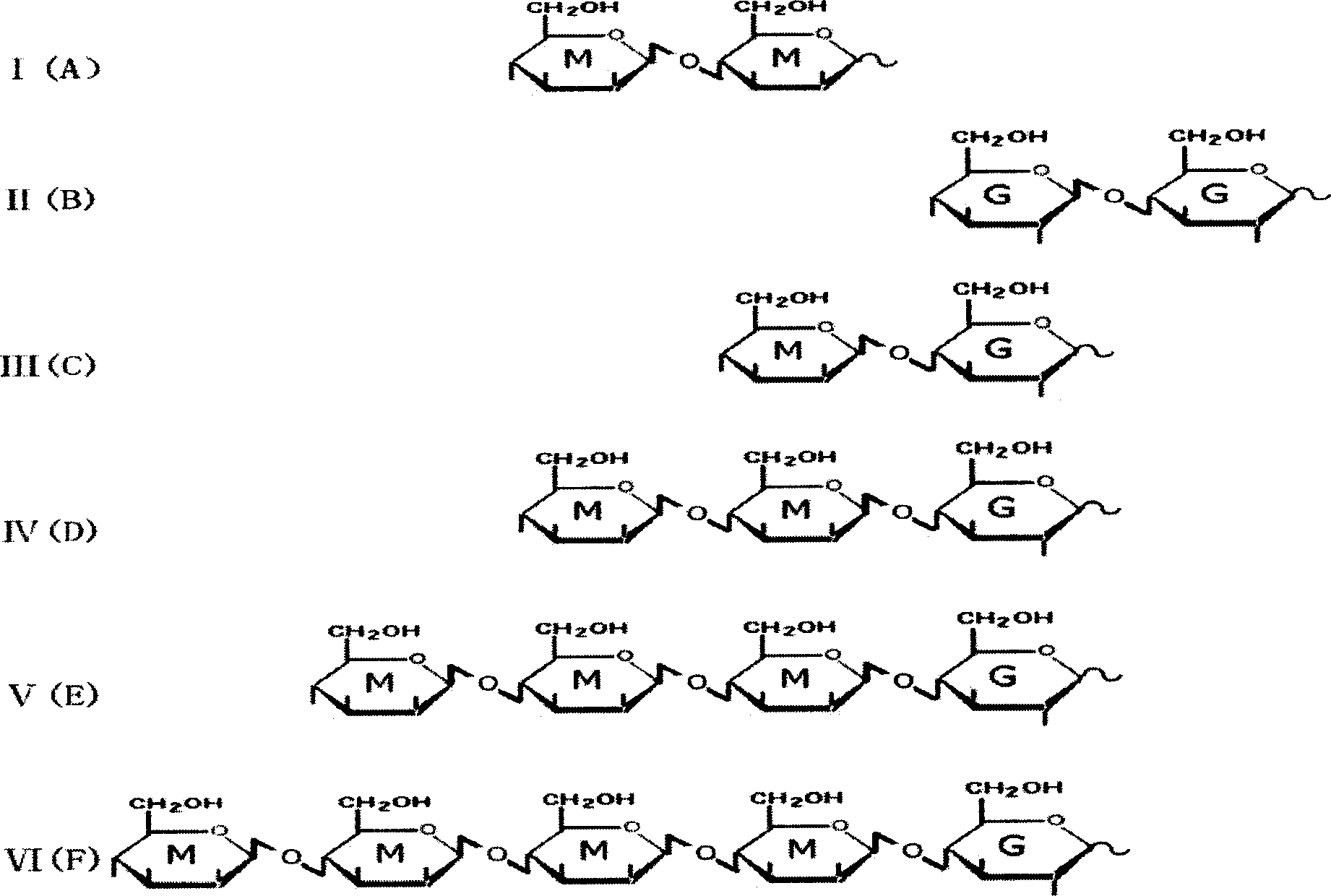

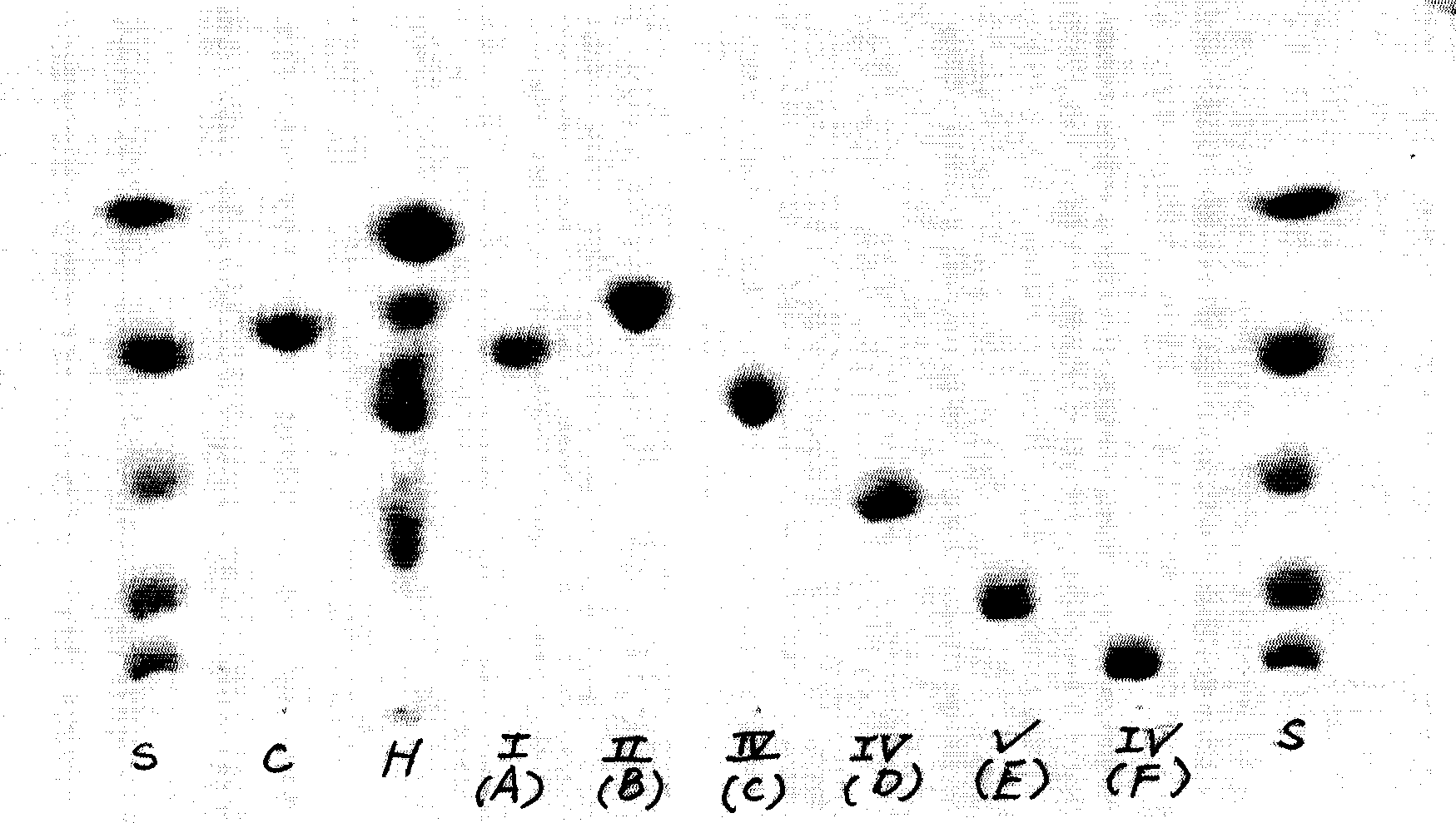

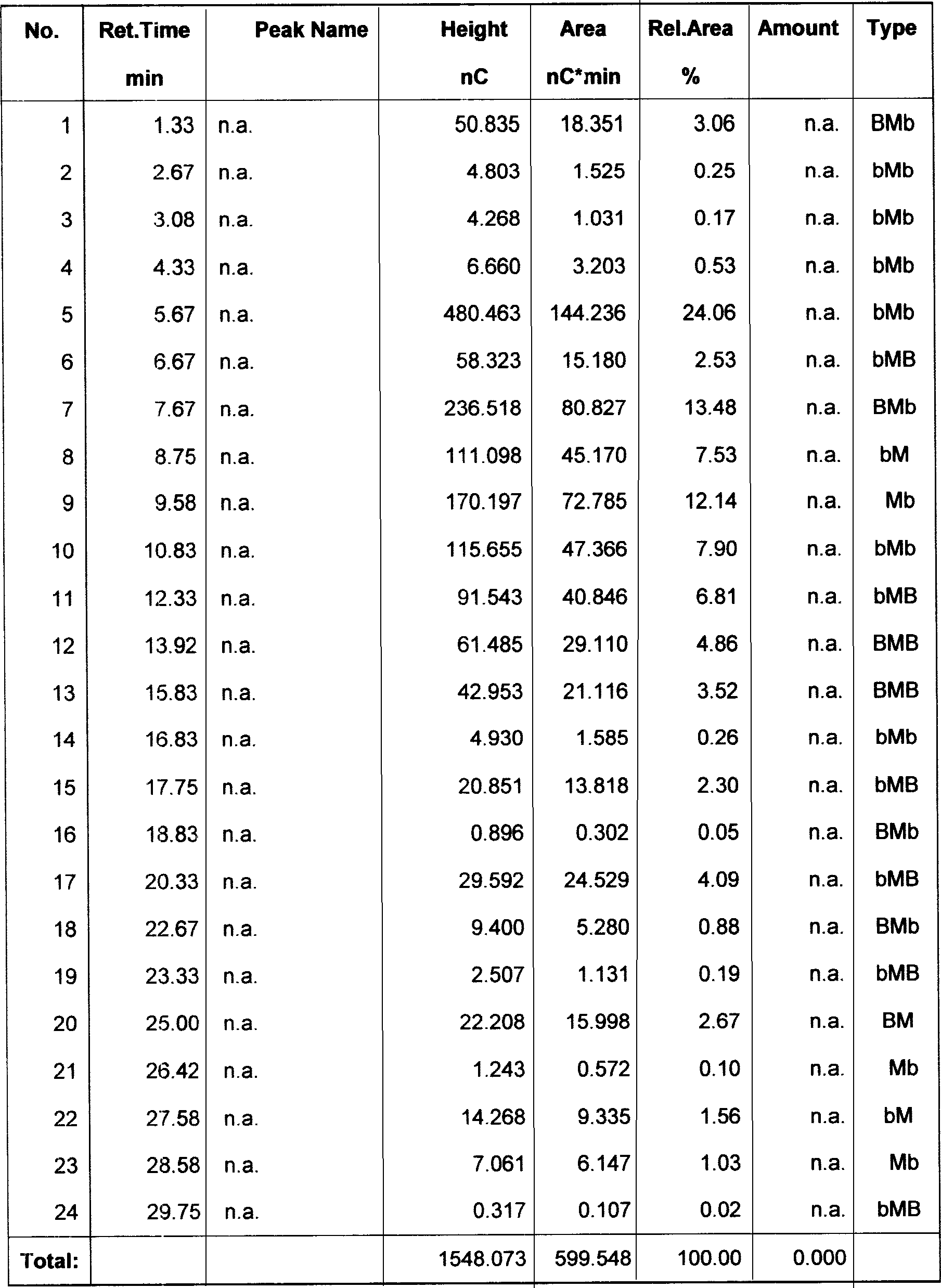

Image

Examples

Embodiment 1

[0044] 1) Enzymatic hydrolysis:

[0045]In 1000 milliliters of distilled water, add 125 grams of konjac powder, stir evenly, adjust its temperature to 45 ° C, and adjust the acidity and alkalinity to pH 5 with 0.5M (molar concentration) NaOH (sodium hydroxide) solution. A mixture of cellulase and hemicellulase (enzyme activity ratio: 3:1) with a total enzyme activity of 12500 u (international units) was added, and the mixture was stirred and reacted at 45° C. and pH 5 for 7 hours. During the reaction, the pH was maintained at 5 by adjusting with 0.5M NaOH solution. After the reaction was finished, inactivate it in a boiling water bath for 15 minutes, and let it stand overnight at room temperature.

[0046] 2) Separation coupling purification:

[0047] The product of the previous step was centrifuged at 3600 rpm for 10 minutes to remove the precipitate. After drying, the precipitate can be used as feed, and can also be put into enzymatic hydrolysis again. The centrifuged mo...

Embodiment 2

[0051] 1) Enzymatic hydrolysis:

[0052] In 1000 milliliters of distilled water, add 110g konjac fine powder, 15 gram centrifugal separation filter residues, 3 gram ultrafiltration membrane separation filter residues, stir evenly, add cellulase and hemicellulase mixture (cellulase enzyme activity: hemicellulase Enzyme activity=3:1, total enzyme activity 12500u), fully mix, adjust its temperature to 50°C, and adjust pH to 5 with 0.5M (molar concentration) sodium hydroxide (NaOH) solution, at 50°C, pH5 The reaction was stirred for 7 hours under certain conditions, and the enzymatic hydrolysis reaction was terminated. During the reaction, the pH was maintained at 5 with 0.5M NaOH solution. After the reaction was terminated, it was inactivated in a boiling water bath for 15 minutes, and left standing overnight at room temperature.

[0053] 2) Separation coupling purification:

[0054] The product of the previous step was centrifuged at 3600 rpm for 10 minutes to remove the prec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com