Cell growth-inhibiting film, medical instrument and stent for digestive organs

A technology for cell proliferation and medical equipment, applied in the field of cell proliferation inhibitory membranes, can solve problems such as hindering the flow of digestive juices, and achieve the effect of avoiding side effects and inhibiting cell proliferation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] There are no particular limitations on the method for preparing the cell growth-inhibiting film of the present invention, and examples include casting an organic solvent solution of a resin onto a substrate, and while evaporating the organic solvent, a A method of generating condensation and evaporating tiny water droplets generated by the condensation.

[0054] More specifically, (1) cast the organic solvent solution of the resin onto the substrate, and slowly evaporate the organic solvent by blowing high-humidity air, and at the same time generate condensation on the surface of the casting liquid, and the evaporation is caused by the The method of tiny water droplets produced by dew; or (2) cast the organic solvent solution of the resin on the substrate under the atmosphere with a relative humidity of 50-90%, and while the organic solvent is evaporated, the liquid on the surface of the casting liquid A method of generating condensation and evaporating tiny water dropl...

Embodiment 1

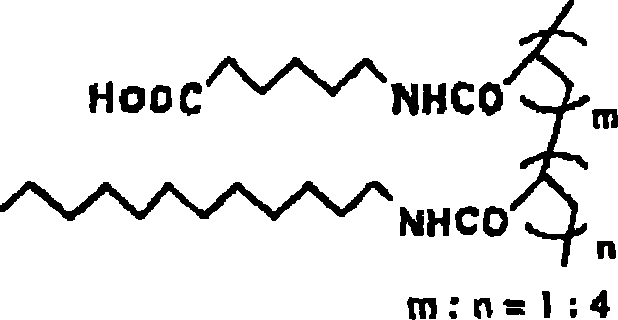

[0120] Polyε-caprolactone (viscosity average molecular weight: 70000, manufactured by Wako Pure Chemical Industries, Ltd.) and Cap resin (weight average molecular weight: 62000, number average molecular weight: 21000) were dissolved in chloroform at a weight ratio of 10:1, and 6 ml of the obtained solution (resin concentration: 0.27% by weight) was similarly spread on a glass dish with a diameter of 10 cm.

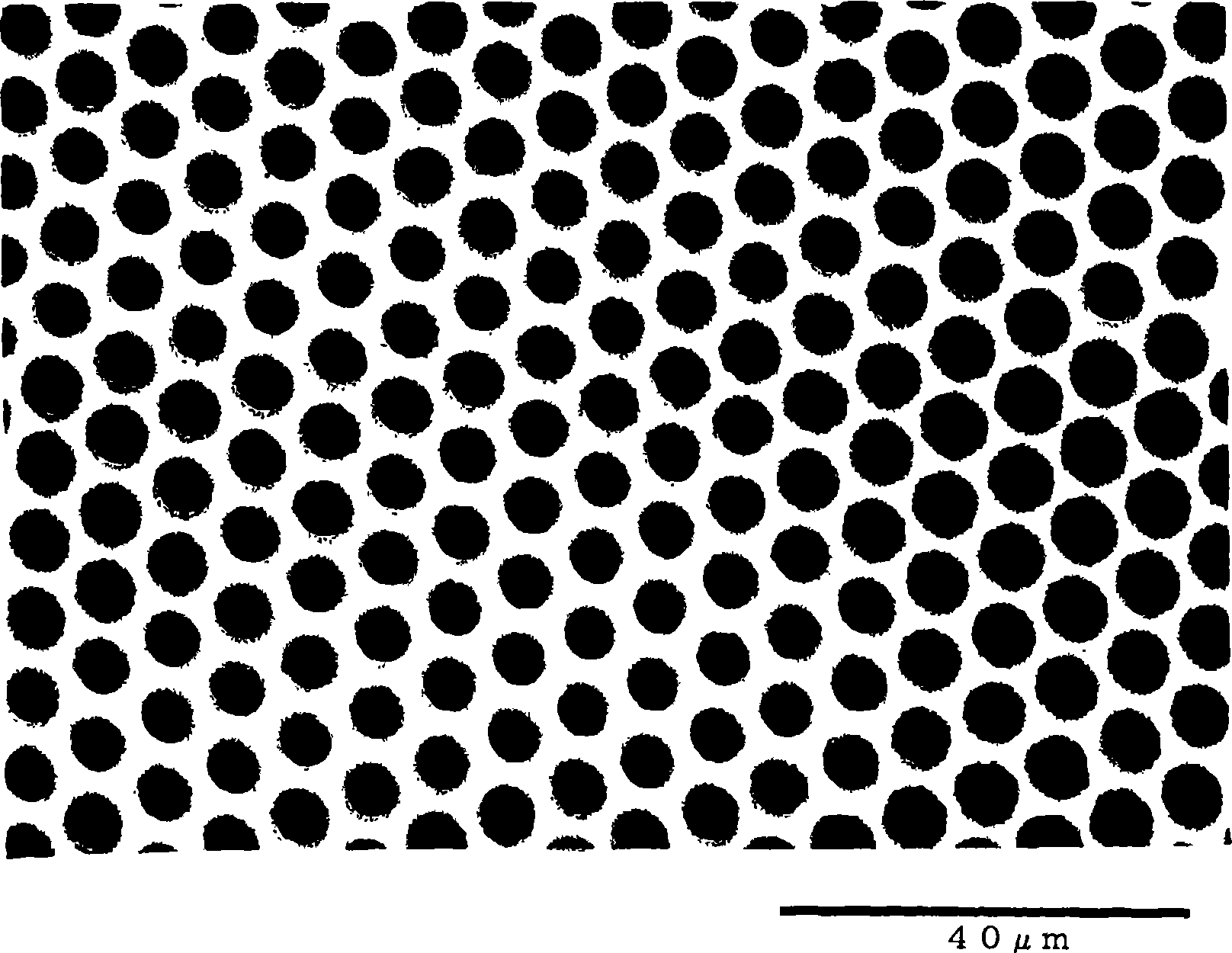

[0121] Next, under an atmosphere of 23.0° C. and a relative humidity of 40%, blow high-humidity air with a relative humidity of 70% to the liquid surface on the glass dish at a flow rate of 2 L / min for 1 minute, thereby obtaining a film thickness of 1 to 30%. Membrane A of 2 μm. When the membrane A was observed at a magnification of 100 times using an optical microscope (BH2, manufactured by Olympus Corporation), it was confirmed that a honeycomb porous structure was formed. The average pore diameter of the pores constituting this porous structure was 3.5 μm, and the vari...

Embodiment 2

[0123] Except that Example 2 was performed under an atmosphere of 24.0° C. and Example 3 was performed under an atmosphere of 25.0° C., membranes B and C having a porous structure of a honeycomb structure were obtained in the same manner as in Example 1.

[0124] Table 1 shows the film thicknesses of the obtained films B and C, the average pore diameters of the pores constituting the porous structure, and the variation coefficient of the pore diameters.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com