Fume-fume hot pipe heater exchanger for fume desulphurization in heat-engine plant

A technology for heat pipe heat exchangers and thermal power plants, which is applied in the direction of heat exchanger types, indirect heat exchangers, heat exchange equipment, etc., which can solve the problems of large floor area, heavy maintenance workload, and high equipment prices, and achieve thermal energy utilization High efficiency, simple and convenient maintenance, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

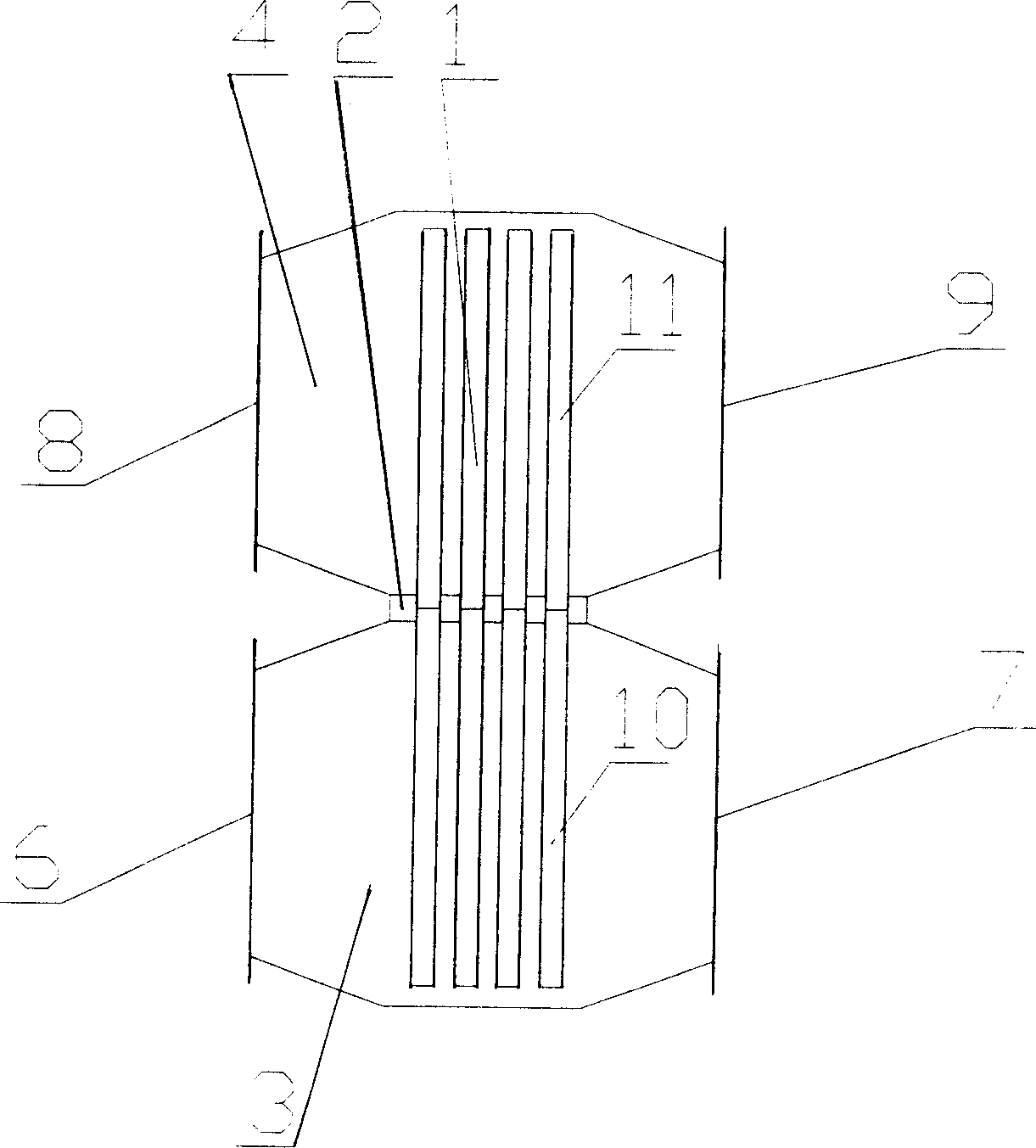

[0011] Such as figure 1 Shown is a schematic structural diagram of a flue gas-flue gas heat pipe heat exchanger for flue gas desulfurization in a thermal power plant. The flue gas-flue gas heat pipe heat exchanger for flue gas desulfurization in a thermal power plant consists of a heat pipe 1, a tube plate 2, The lower shell 3 and the upper shell 4 are composed, the lower shell 3 and the upper shell 4 are connected by the tube sheets 2 on both sides, the two sides of the lower shell 3 are respectively provided with a hot flue gas inlet 6 and a hot flue gas outlet 7, and the upper The two sides of the housing 4 are respectively provided with a cold flue gas inlet 8 and a cold flue gas outlet 9, and the heat pipe 1 is vertically arranged between the lower housing 3 and the upper housing 4, and the heat pipe 10 arranged in the lower housing 3 adopts low-temperature corrosion-resistant It is made of ordinary carbon steel or Corten steel with low requirements and low price. The hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com