Silicon carbone compound negative polar material of lithium ion battery and its preparation method

A lithium-ion battery, silicon-carbon composite technology, applied in electrode manufacturing, battery electrodes, secondary batteries, etc., can solve the problems of reducing the amount of lithium intercalation, unable to give full play to the high capacity characteristics of Si, hindering lithium diffusion behavior, etc., and achieve improvement. Effects of diffusion behavior, improved first-time efficiency and cycle stability, excellent high-current discharge capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

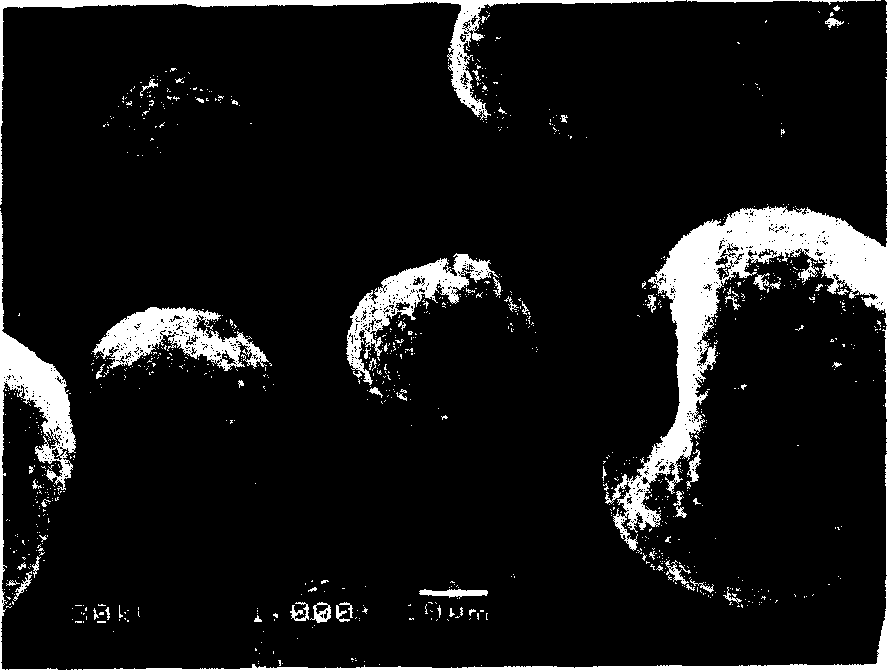

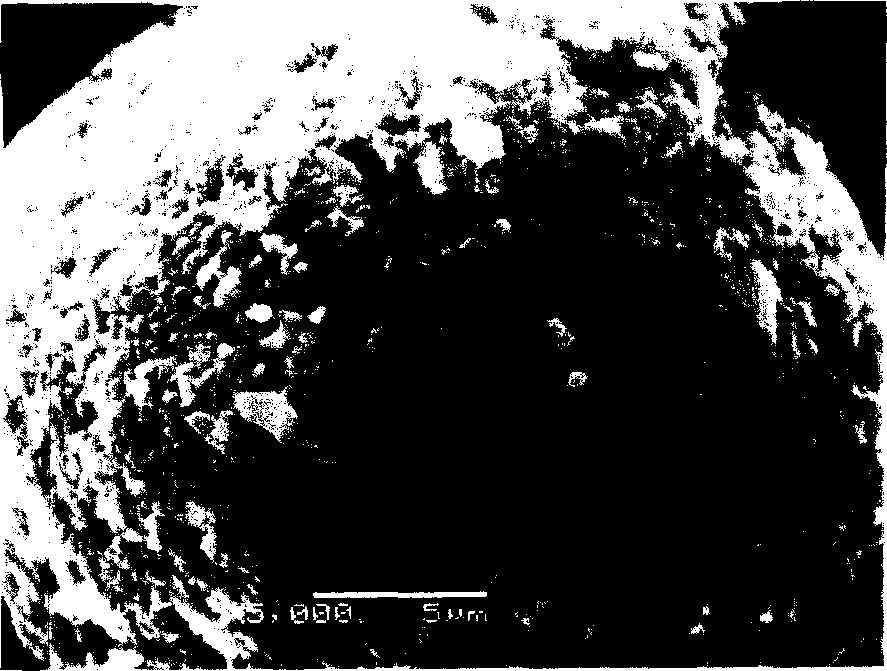

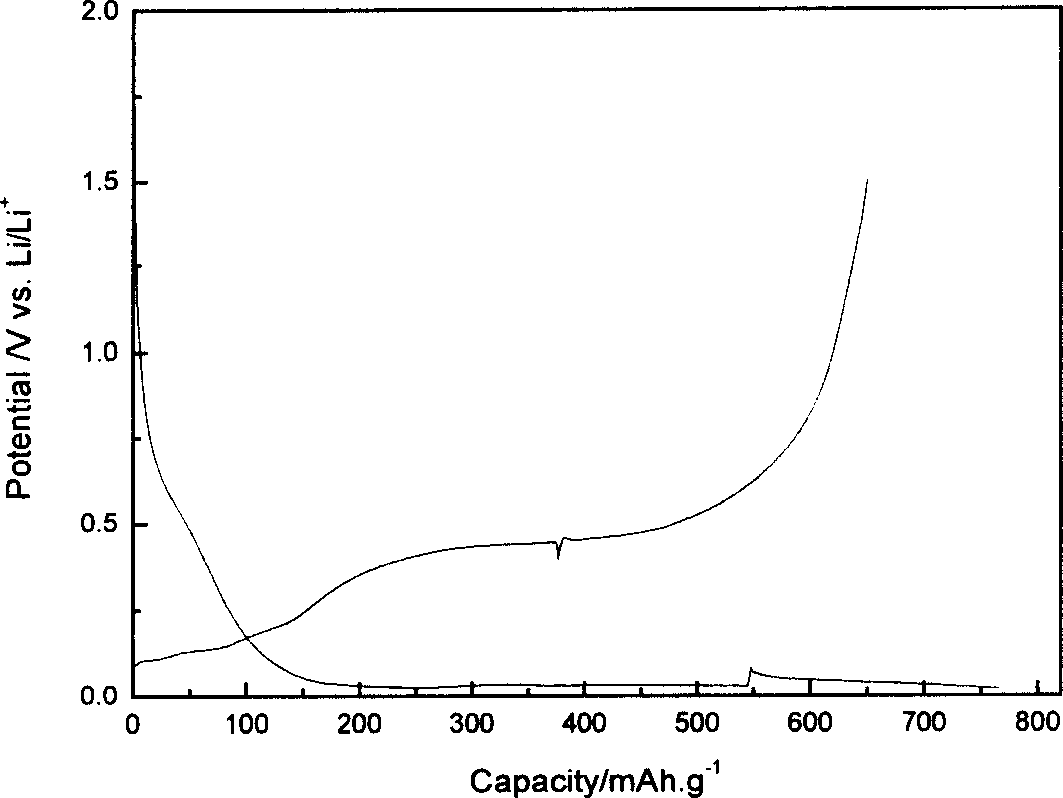

[0058] Embodiment 1, prepare silicon carbon Si-G-C-Li 2 CO 3 Composite negative electrode material: Mechanical high-energy ball milling of silicon powder with a particle size of 75 μm to 0.5 μm in an argon atmosphere to obtain ultra-fine silicon powder; preparation of natural graphite with a particle size of 70 μm and a carbon content of more than 95% by pulverization, classification, shaping and purification Spherical graphite with a carbon content of 99.9% or more and a particle size of 1 μm was obtained; the obtained ultrafine silicon powder 20wt% and 80wt% spherical graphite were mixed and granulated in a double-helix mixer for 6 hours to make a composite particle matrix; the composite particle Mix the matrix with 10wt% phenolic resin and stir for 10 hours, then dry and granulate at 300°C; carbonize the composite material coated with phenolic resin, heat it to 1100°C in an argon atmosphere, keep it warm for 3 hours, and then lower it to room temperature , crushed and disp...

Embodiment 2

[0060] Example 2, preparation of silicon carbon Si-Mg-G-C-LiOH composite negative electrode material: Si-Mg powder with a particle size of 75 μm, containing 50 wt% Si, was mechanically high-energy ball milled to 0.1 μm in an argon atmosphere to obtain ultrafine Si -Mg powder; the natural graphite with a particle size of 70 μm and a carbon content of more than 95% is pulverized, classified, shaped and purified to prepare spherical graphite with a carbon content of more than 99.9% and a particle size of 3 μm; the prepared ultrafine Si-Mg powder 30wt % and 70wt% spherical graphite were mixed in a mixing granulator for 1 hour and granulated to make a composite particle matrix; the composite particle matrix was mixed with 2.5wt% styrene-butadiene rubber emulsion for 4 hours, and then dried and granulated at 200 ° C; The coated composite material is carbonized, heated to 700°C in an argon atmosphere, kept for 5 hours, then lowered to room temperature, crushed and dispersed to 10 μm; ...

Embodiment 3

[0062] Example 3, preparation of silicon carbon Si-Fe-G-C-LiF composite negative electrode material: Si-Fe powder with a particle size of 75 μm, containing 75wt% Si, was mechanically high-energy ball milled to 1 μm in an argon atmosphere to obtain ultrafine Si- Fe powder; the natural graphite with a particle size of 70 μm and a carbon content of more than 95% is pulverized, classified, shaped and purified to prepare spherical graphite with a carbon content of more than 99.9% and a particle size of 5 μm; the prepared ultrafine Si-Fe powder 2wt% and 98wt% spherical graphite were mixed in a mixing granulator for 6 hours to make a composite particle matrix; the composite particle matrix was mixed with 1wt% polyvinyl alcohol solution and stirred for 10 hours by wet method, and then dried and granulated at 200 ° C; the coated The final composite material is carbonized, heated to 1500°C in an argon atmosphere, kept for 1 hour, then lowered to room temperature, crushed and dispersed to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com