Filament of neutralization cathode in Kaufman ion source, and method

A technology of Kaufman ion source and cathode filament, which is applied in the field of ion beams, can solve the problems that limit the wide application of Kaufman ion source and time-consuming, and achieve the effects of prolonging continuous working time, improving life, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

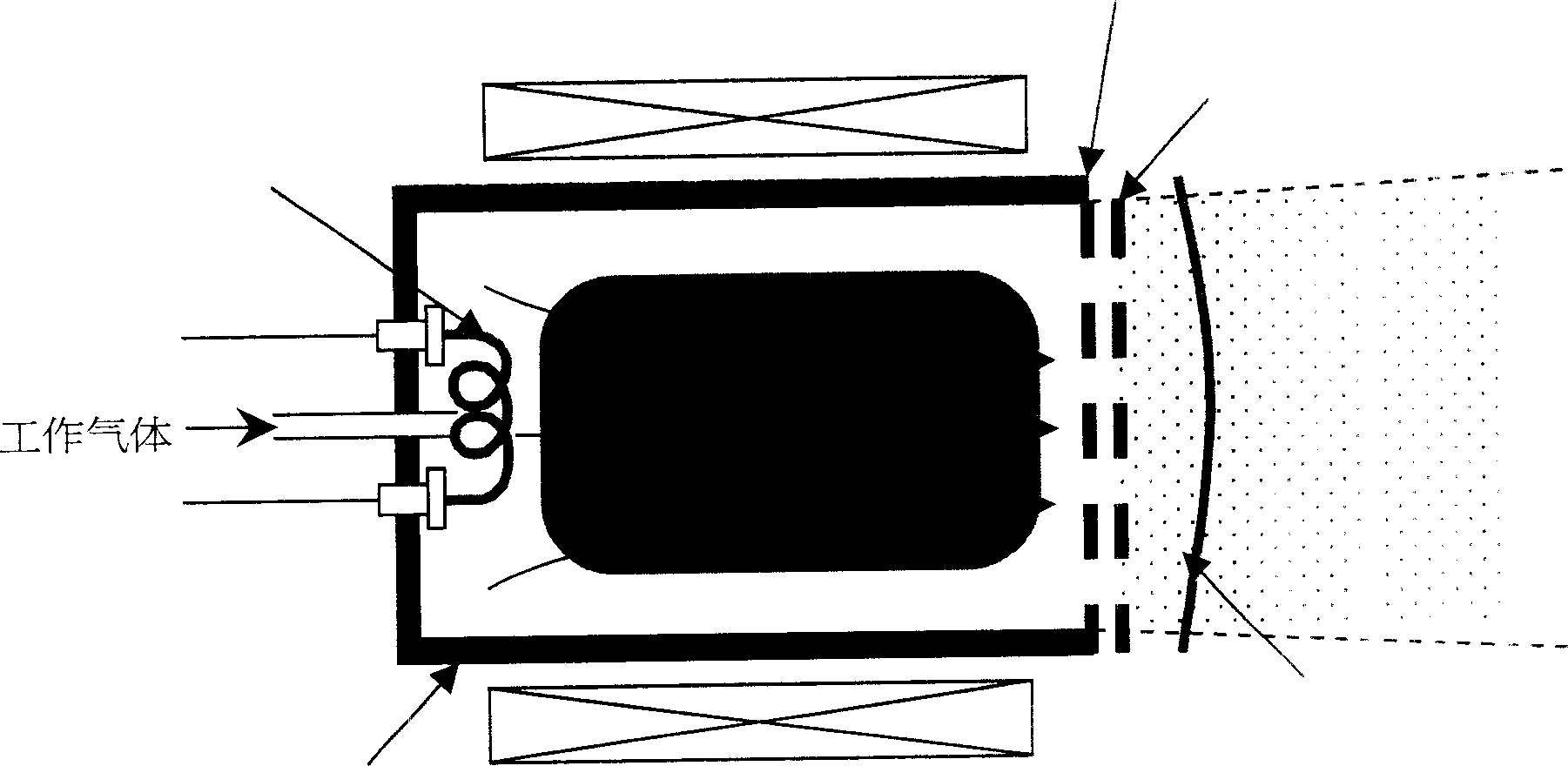

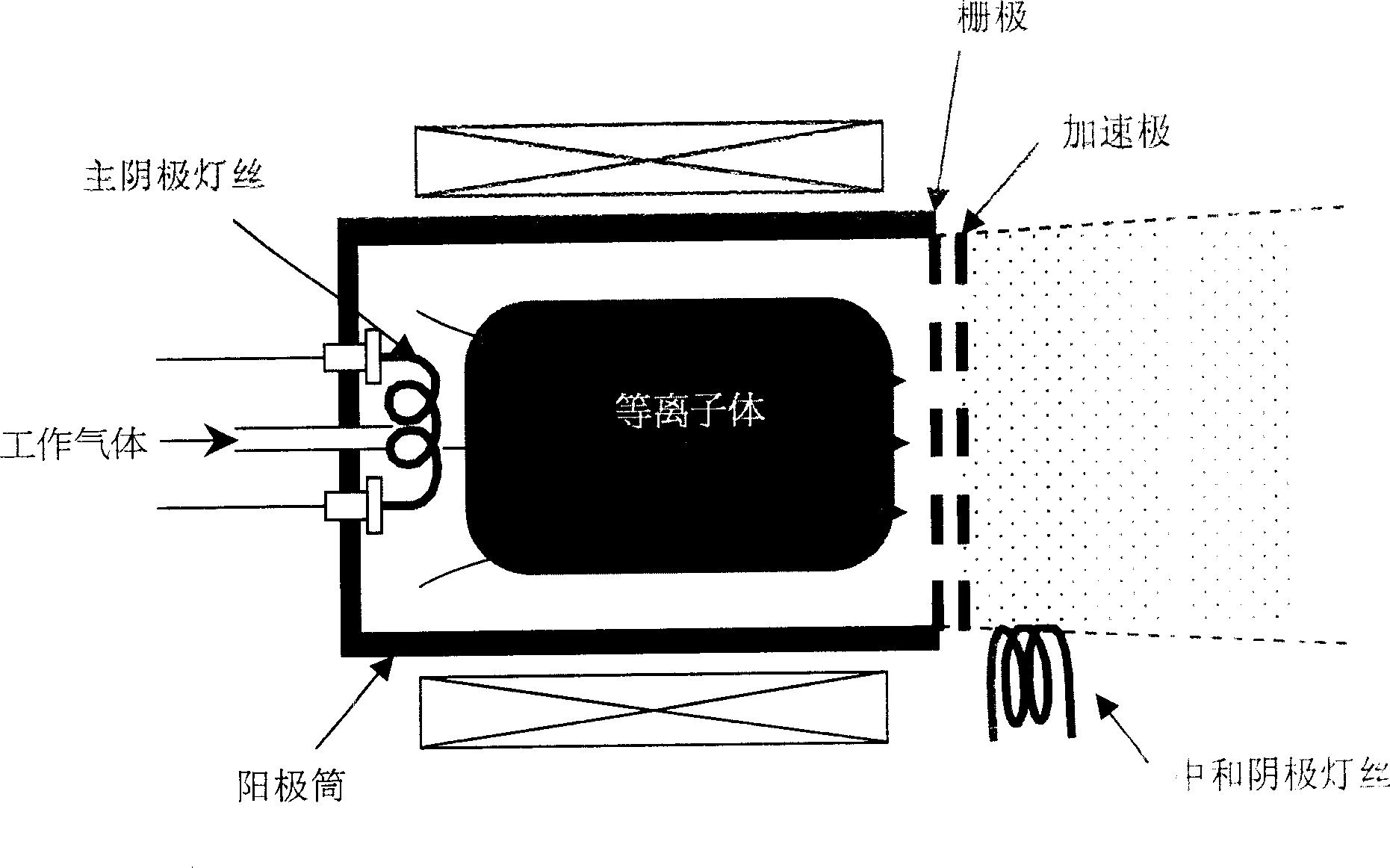

[0028] Specific implementation methods (taking the Φ5cm ion source as an example)

[0029] A method for manufacturing a neutralization cathode filament in a Kaufmann ion source:

[0030] 1) Wind a refractory metal tungsten (W) wire with a length of 60mm and a diameter of 0.4mm into a spiral filament, and bend it into an arc with a radius of curvature of 2.5cm for use;

[0031] 2) Remove the submerged neutralization cathode filament on the original Kaufmann ion source;

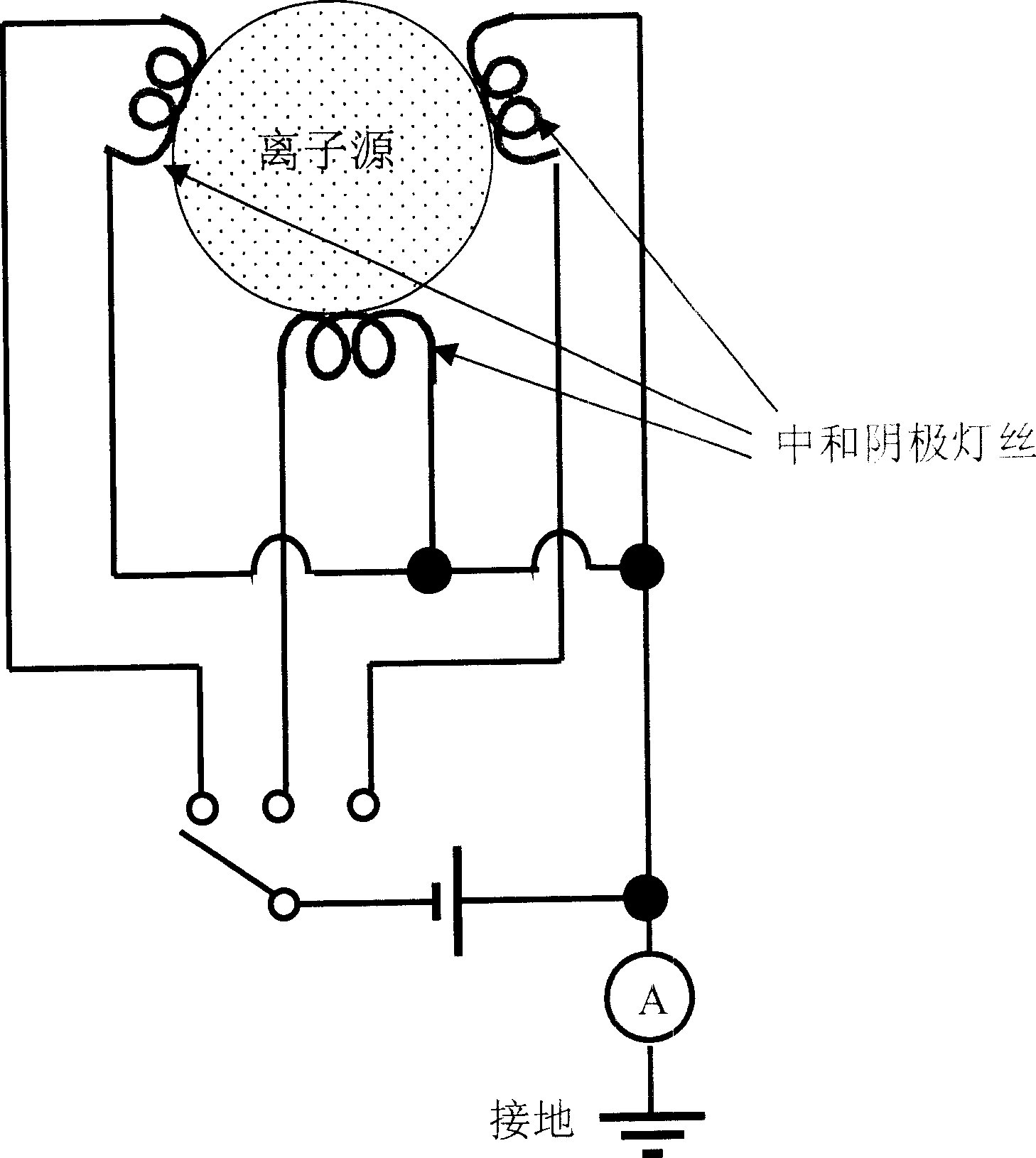

[0032] 3) Install three new helical neutralization filaments around the Kaufman ion source, the filaments are evenly distributed around the ion source and placed outside the ion beam;

[0033] 4) Connect one end of the three neutralizing cathode filaments together outside the ion source and connect to the positive pole of the filament current source, the positive pole of the current source is grounded through the ammeter, the other end of the three neutralizing cathode filaments is connected to one side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com