Method and apparatus for producing hydrogen

A manufacturing method and a manufacturing device technology, which are applied in the field of manufacturing high-purity hydrogen and can solve problems such as consumption of natural gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

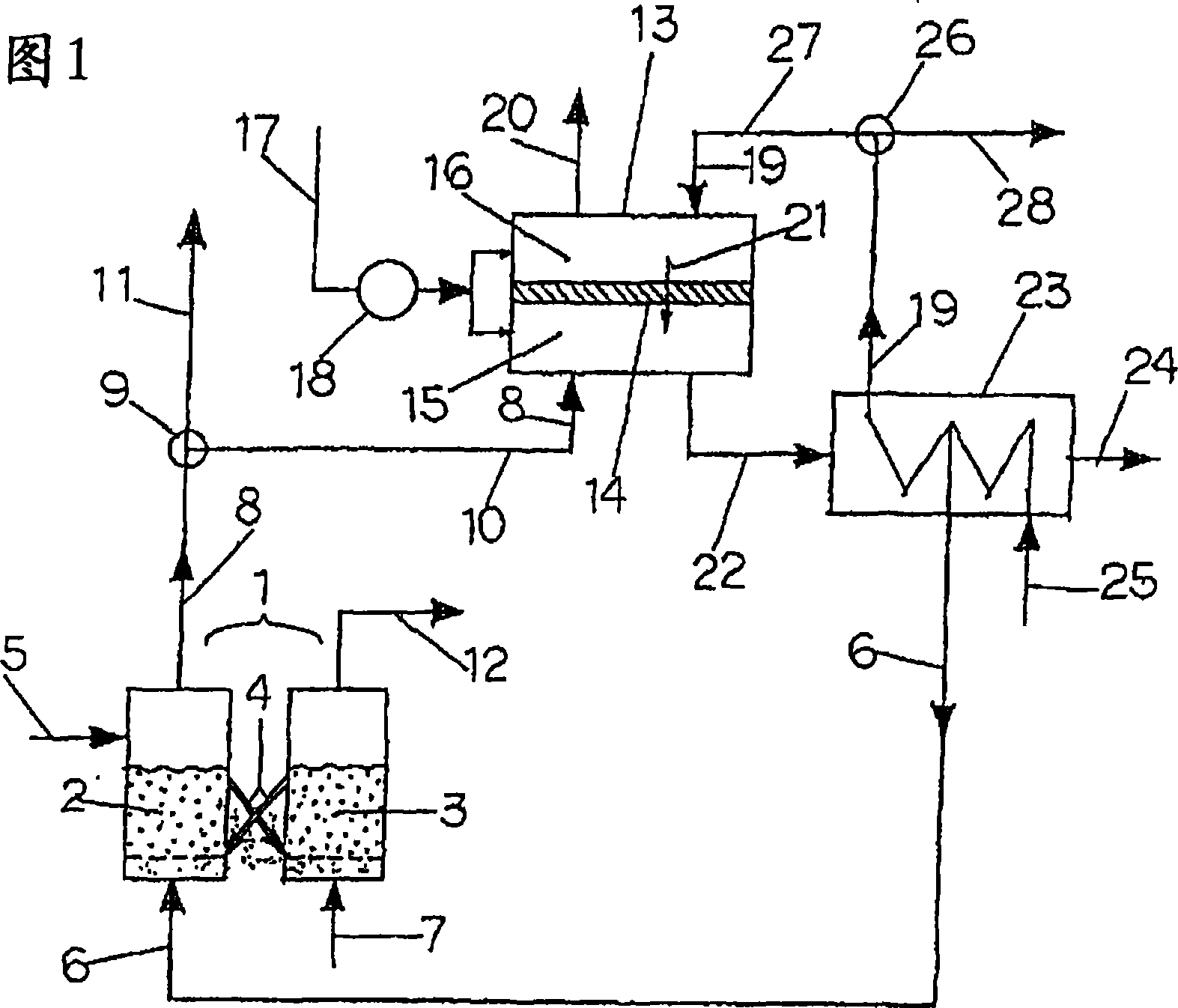

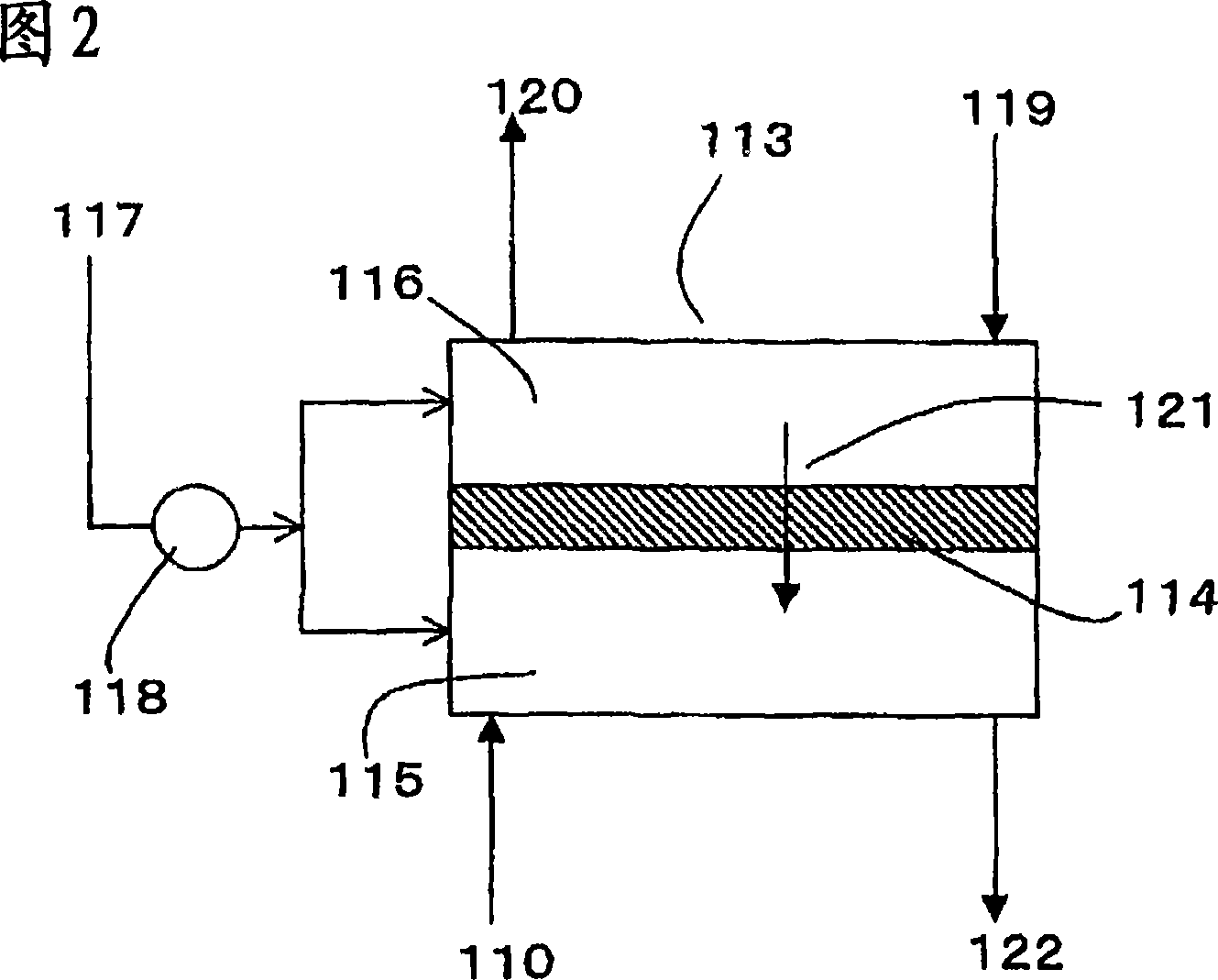

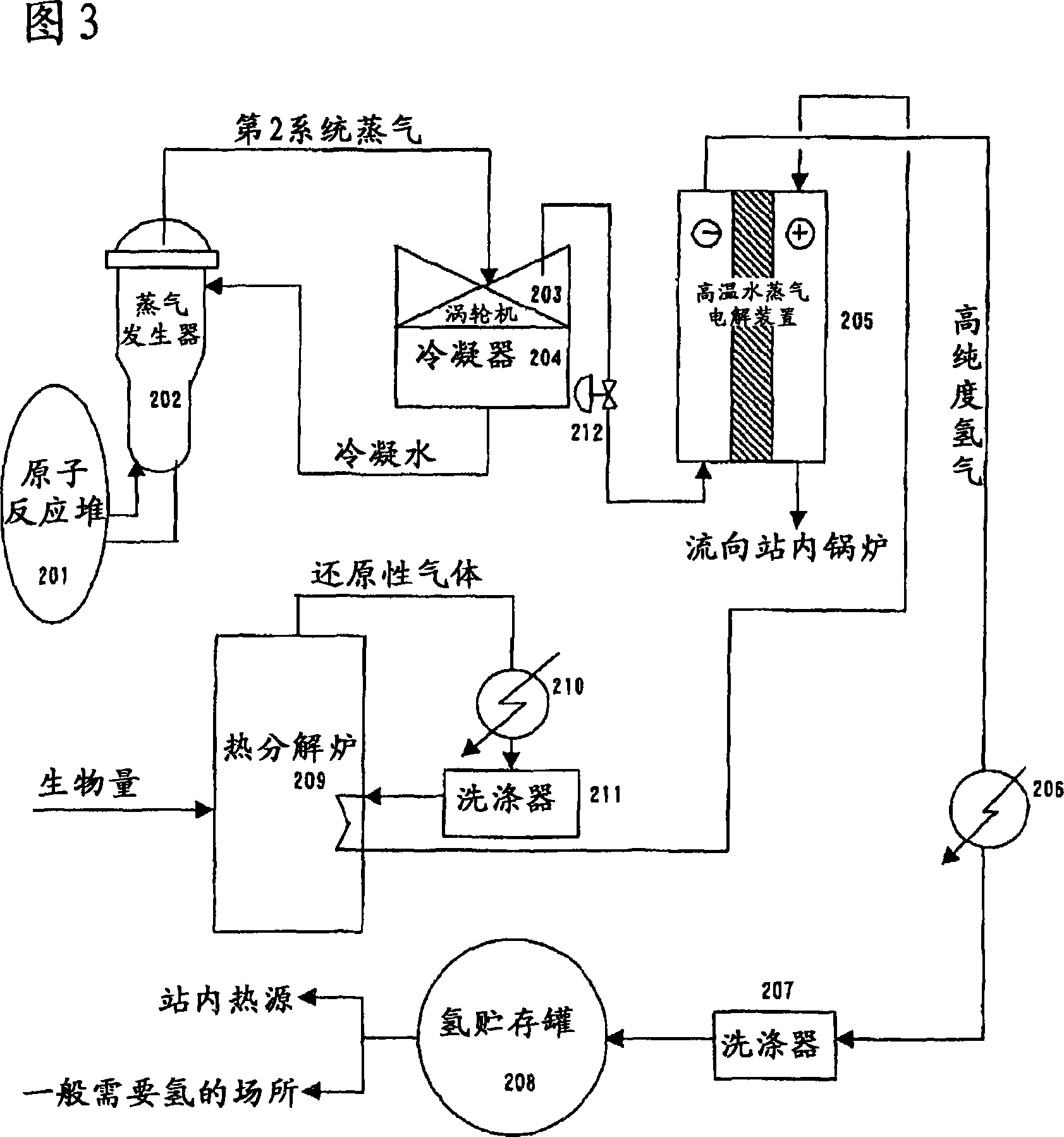

Method used

Image

Examples

Embodiment

[0263] The following examples show that the durability of the electrolysis device can be significantly improved by making the concentration of sulfur in the reducing gas supplied to the anode side of the high-temperature steam electrolysis device 1 ppm or less, preferably 0.1 ppm or less.

[0264] According to the process shown in Figure 23, the sulfur concentration from the gas cylinder is adjusted to 100ppm, 10ppm, 1ppm, and 0.1ppm. After the methane gas is adjusted to about 700°C with a temperature regulator, it is supplied to the electrolyzed by the solid oxide electrolyte diaphragm. The anode side of the high-temperature steam electrolysis cell is divided into an anode side and a cathode side, and high-temperature steam of about 700°C is supplied to the cathode side, and electric power is applied to the electrodes to perform steam electrolysis. Yttrium-stabilized zirconia (YSZ) was used as the solid oxide electrolyte.

[0265] The hydrogen-containing gas generated from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com