Multiple apertures releasing osmosis pump and preparation process thereof

一种渗透泵控释、群孔的技术,应用在渗透输送、医药配方、含有效成分的医用配制品等方向,能够解决废品率高渗透泵产品推广、生产难度大、生产周期长等问题,达到提高可靠性和稳定性、劳动强度降低、设备成本降低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

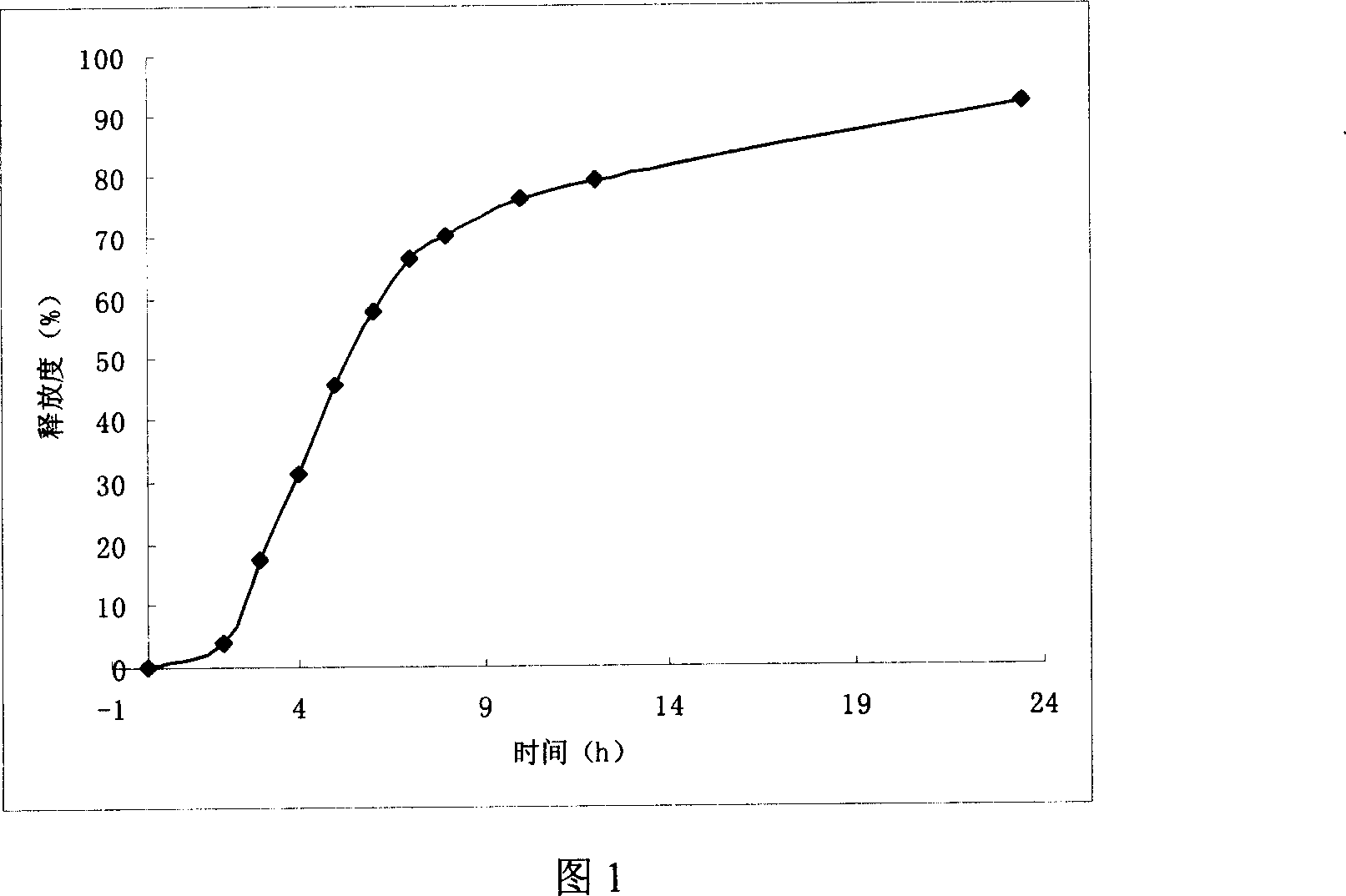

Embodiment 1

[0036] Chip composition:

[0037] Venlafaxine Hydrochloride 75g

[0038] Microcrystalline Cellulose 45g

[0039] NaCl 35g

[0041] Coating film composition:

[0042] Cellulose acetate 21g

[0043] Macrogol 6000 9g

[0044] Dibutyl sebacate 2g

[0045] Make 1000 tablets by the following preparation method:

[0046] (1) Tablet core preparation: take sodium chloride and pulverize it, cross a 100 mesh sieve, mix evenly with venlafaxine hydrochloride and microcrystalline cellulose, use ethanol as a wetting agent, make a soft material, cross a 30 mesh sieve for granulation, 45 Dry at ℃ for 2 hours, granulate, add magnesium stearate, mix well, compress into tablets, and compress 1000 tablets by conventional tablet technology.

[0047] (2) Tablet core coating: take cellulose acetate, add 600ml of acetone, stir to dissolve; take another polyethylene glycol, put it in a 50ml measuring bottle, add water to dissolve it, and then add it to the above 1...

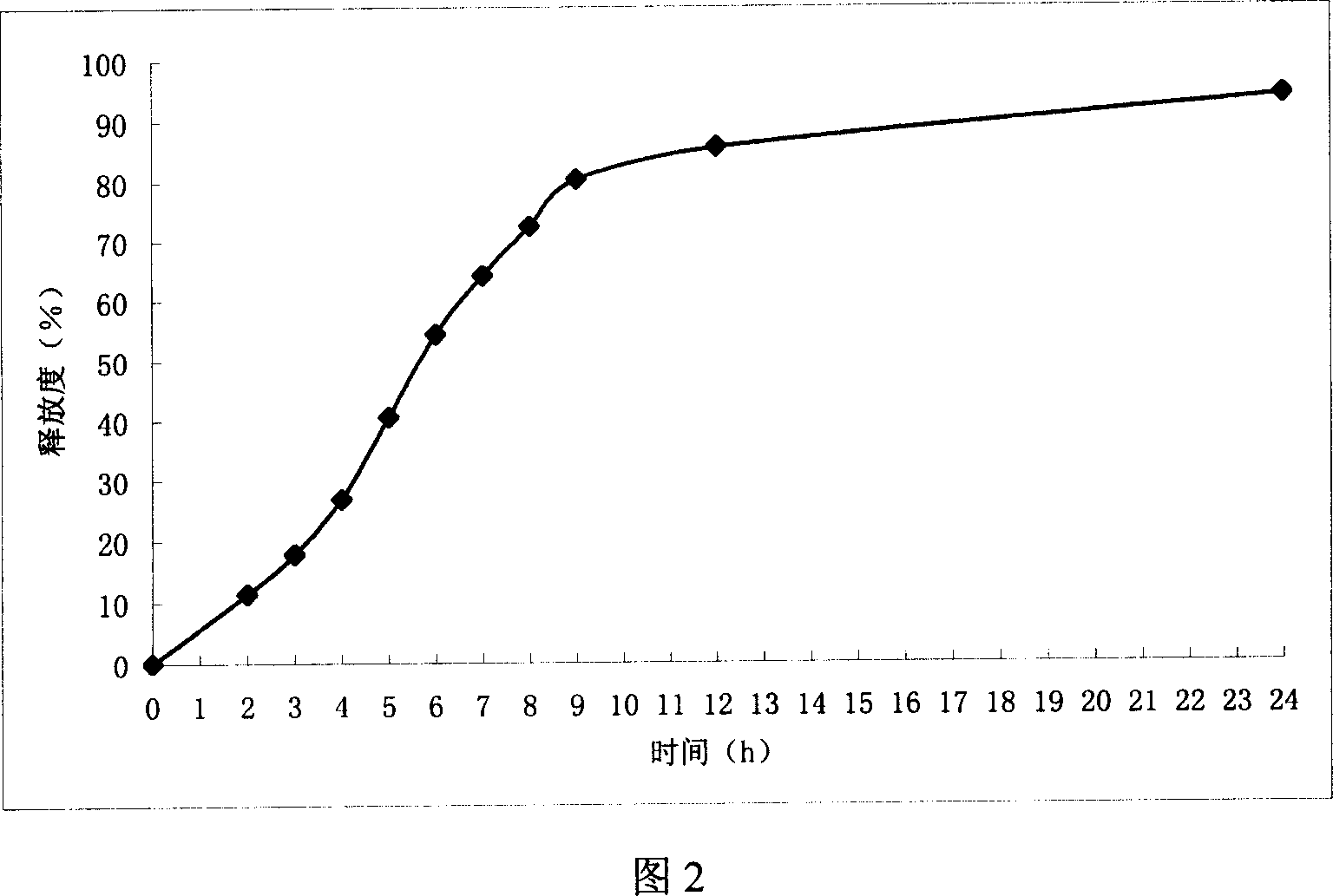

Embodiment 2

[0050] Chip composition:

[0051] Venlafaxine Hydrochloride 75g

[0052] Alginic acid 30g

[0053] Propylene Glycol Alginate 20g

[0054] Mannitol 30g

[0056] Coating film composition:

[0057] Polyacrylic resin 5g

[0058] Ethylcellulose 14g

[0059] Hydroxypropyl Cellulose 6g

[0060] Triethyl citrate 2g

[0061] Make 1000 tablets by the following preparation method:

[0062] (1) Tablet core preparation Take mannitol and pulverize it, pass through a 100-mesh sieve, mix evenly with venlafaxine hydrochloride, alginic acid, and propylene glycol alginate, use ethanol as a wetting agent, make a soft material, and pass through a 30-mesh sieve to granulate , dried at 45°C for 2 hours, granulated, added with magnesium stearate, mixed evenly, compressed into tablets, and compressed into 1000 tablets using conventional tablet technology.

[0063] (2) Tablet core coating: take polyacrylic acid resin, ethyl cellulose, hydroxypropyl cellulose, ad...

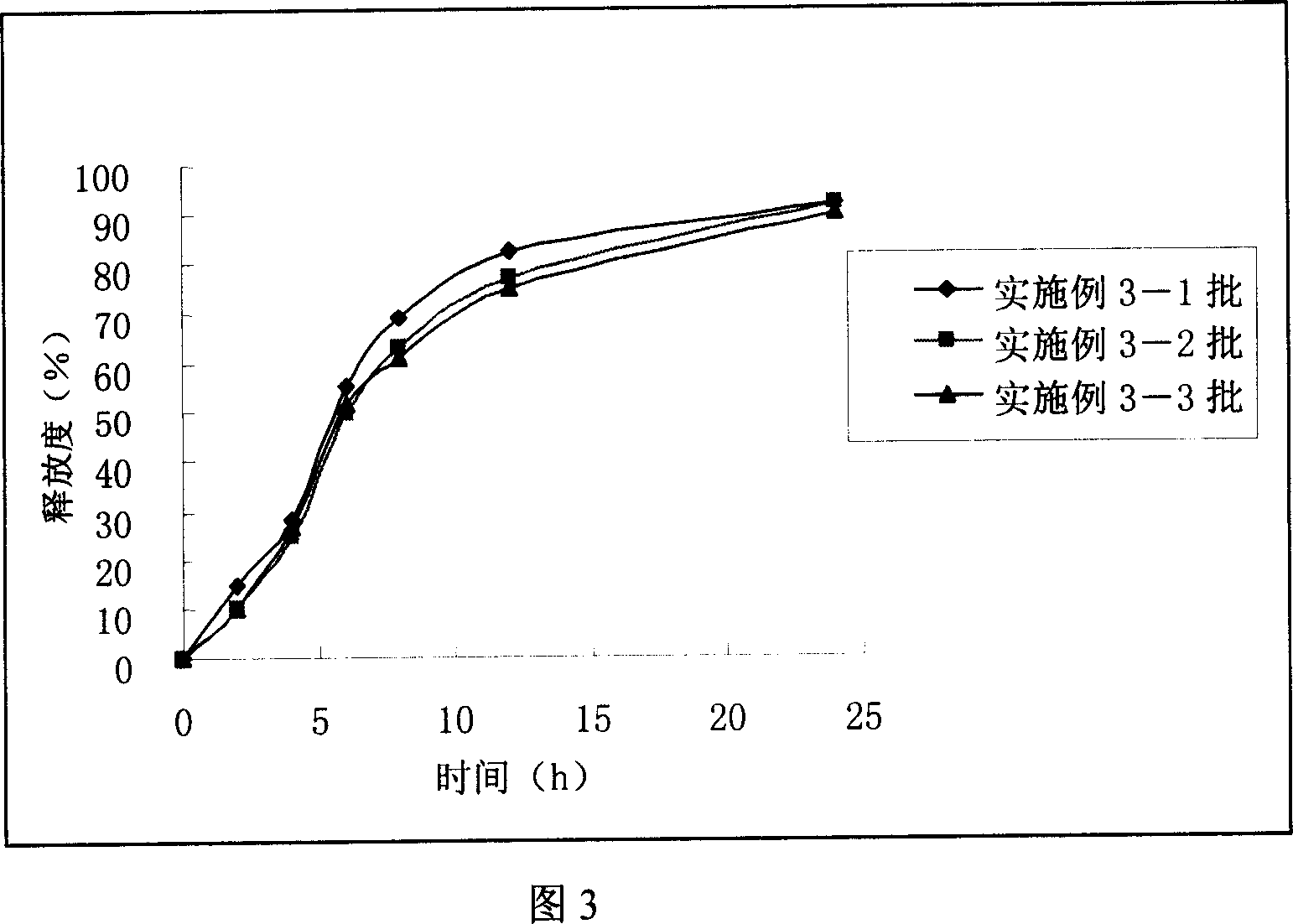

Embodiment 3

[0066] Chip composition:

[0067] Venlafaxine Hydrochloride 75g

[0068] Microcrystalline Cellulose 60g

[0070] Magnesium stearate 0.9g

[0071] Coating film composition:

[0072] Cellulose acetate 25g

[0073] Polyethylene glycol (6000) 11g

[0074] Dibutyl sebacate 2.5g

[0075] The composition of the film coating layer containing the main drug:

[0076] Venlafaxine Hydrochloride 10g

[0077] Hypromellose 20g

[0078] Polyethylene glycol (4000) 2g

[0079] Make 1000 tablets by the following preparation method:

[0080] (1) Tablet core preparation: crush the sodium chloride and set aside. Pass 75g of venlafaxine hydrochloride, 30g of microcrystalline cellulose, and 40g of sodium chloride through a 60-mesh sieve, and mix well. Add 10% polyvinylpyrrolidone k-30 ethanol solution in an appropriate amount to make a soft material, pass through a 30-mesh sieve to granulate, and place it in an oven to heat and dry at 40°C. The prepared granu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com