Semiconductor manufacturing process using ultra-low dielectric materials

A technology of ultra-low dielectric materials and low dielectric materials, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problems of dielectric constant change, weak resistance to mechanical stress, and difficult to remove. To achieve the effect of preventing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

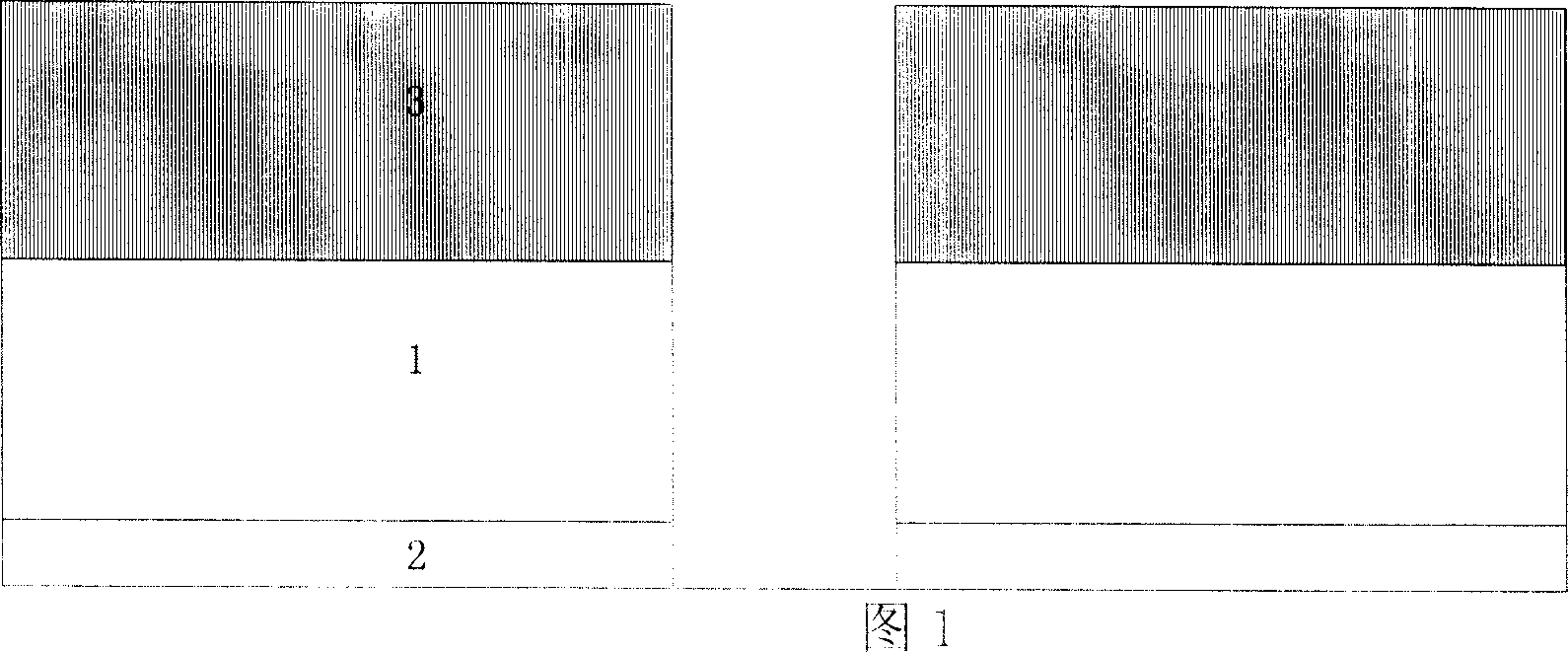

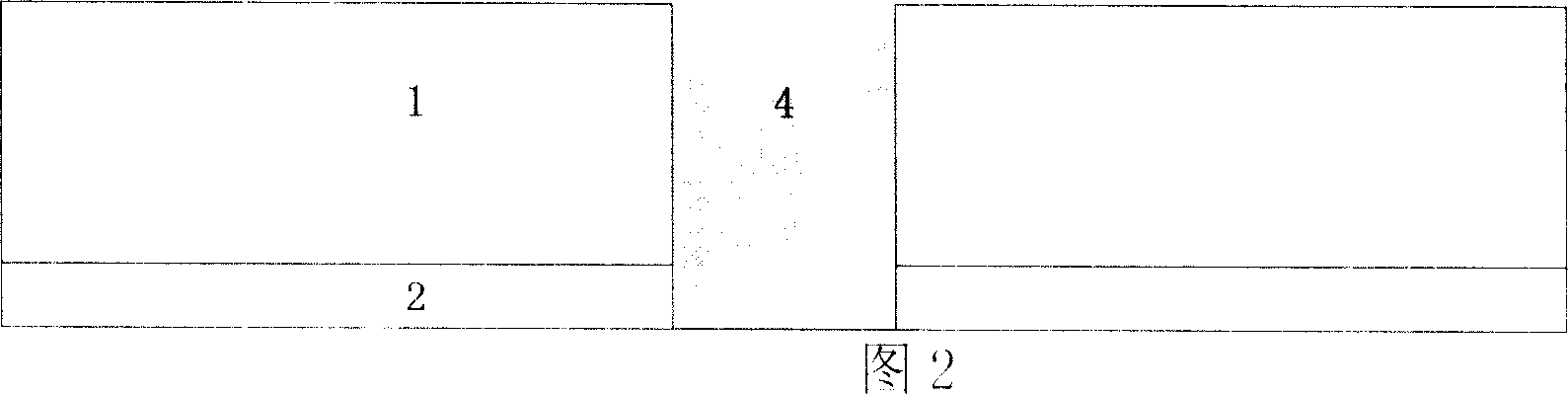

[0039] Now in conjunction with accompanying drawing, specific embodiment of the present invention is described in further detail:

[0040]First, as shown in Fig. 1, the etching barrier layer 2 and the intermetallic dielectric layer 1 at the bottom of the growth metal wire, the etching barrier layer, its raw material source is helium, neon, argon, krypton or xenon inert gas, carbon monoxide, carbon dioxide, sulfur dioxide , silane, methane, or nitrogen, manufactured by process, the thickness is 30 nanometers, 40 nanometers, 50 nanometers, 60 nanometers, 70 nanometers. 80nm, 90nm, 100nm, 110nm, 120nm, each processing time is 50 seconds, 100 seconds, 150 seconds, 200 seconds, 250 seconds, 300 seconds, 350 seconds, 400 seconds, 450 seconds and 500 seconds , the air pressure is 5 Torr, 10 Torr, 30 Torr and 50 Torr, the power is 100 W, 150 W and 300 W respectively; the temperature is 150 ° C, 175 ° C, 200 ° C, 250 ° C, 300 ° C, 350 ° C At a temperature of 400°C, the product can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com