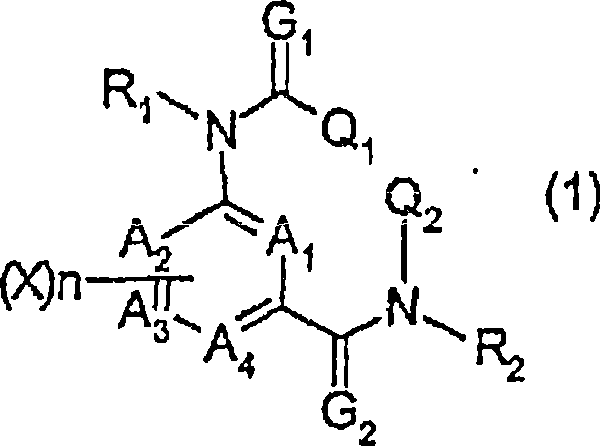

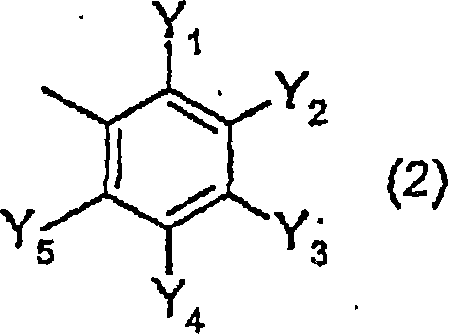

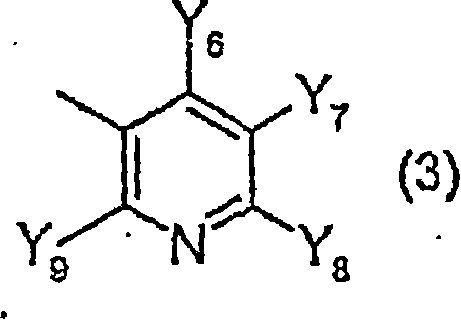

Amide derivatives, process for production of the same, and method for application thereof as insecticide

A compound, C1-C4 technology, applied in the fields of botanical equipment and methods, biocides, animal repellants, etc., can solve problems such as undocumented insect activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0574] Preparation of N-(2,6-Dimethyl-4-heptafluoroisopropyl)phenyl 3-nitrobenzamide

[0575] Add 20.0g of 2,6-dimethyl-4-heptafluoroisopropylaniline and 11.0g of pyridine to 100ml of tetrahydrofuran, stir at room temperature to make a solution, and slowly drop 3 dissolved in 20ml of tetrahydrofuran into the solution. -Nitrobenzoyl chloride 13.0g. After stirring for 10 hours at room temperature, ethyl acetate and water were added to the reaction solution. After the liquid separation operation, the organic layer was separated and dried with anhydrous magnesium sulfate. The above solution was filtered, the filtrate was collected, and the residue obtained by distilling off the solvent under reduced pressure was washed with a hexane-diisopropyl ether mixed solvent to obtain 26.0 g (yield 85%) of a white solid of the target product.

[0576] 1 H-NMR(CDCl 3 , Ppm) δ 2.33 (6H, s), 7.37 (2H, s), 7.68 (1H, s), 7.72 (1H, t, J = 8.1 Hz), 8.28 (1H, d, J = 8.1 Hz), 8.44 (1H, dd, J = 1.2, 8.1 H...

Embodiment 1-2

[0578] Preparation of N-(2,6-Dimethyl-4-heptafluoroisopropyl)phenyl 3-aminobenzamide (Compound No. I-2)

[0579] Add 0.90 g of N-(2,6-dimethyl-4-heptafluoroisopropyl) phenyl 3-nitrobenzamide and 1.56 g of stannous chloride anhydride to 25 ml of ethanol, and at room temperature Stir to make a solution, add 2ml of concentrated hydrochloric acid to the solution, and stir at 60°C for 1 hour. After returning to room temperature, the reaction solution was poured into water, and potassium carbonate was used for neutralization. After adding ethyl acetate and removing insoluble matter by filtration, the organic layer was separated and dried with anhydrous magnesium sulfate. The solution was filtered, the filtrate was collected, and the residue obtained by distilling off the solvent under reduced pressure was washed with hexane to obtain 0.44 g (yield 53%) of a white solid of the target product.

[0580] 1 H-NMR(CDCl 3 , Ppm) δ 2.34 (6H, s), 3.87 (2H, broad), 6.86-6.89 (1H, m), 7.20-7.35 (6...

Embodiment 1-3

[0582] Preparation of N-(2,6-Dimethyl-4-heptafluoroisopropyl)phenyl 3-(benzoylamino)benzamide (Compound No. 10)

[0583] Add 0.25 g of N-(2,6-dimethyl-4-heptafluoroisopropyl) phenyl 3-aminobenzamide and 0.06 g of pyridine to 5 ml of tetrahydrofuran and stir at room temperature to make a solution. 0.09 g of benzoyl chloride dissolved in 1 ml of tetrahydrofuran was added dropwise. After stirring for 1 hour at room temperature, ethyl acetate and 1N hydrochloric acid were added, the organic layer was separated, and the organic layer was washed once with a saturated sodium bicarbonate aqueous solution, and dried with anhydrous magnesium sulfate. The above solution was filtered, the filtrate was collected, and the solid precipitated by distilling off the solvent under reduced pressure was washed with diisopropyl ether to obtain 0.29 g (yield: 92%) of a white solid of the target product.

[0584] 1 H-NMR(DMSO-d 6 , Ppm) δ 2.37 (6H, s), 7.34 (2H, s), 7.46-7.57 (4H, m), 7.75 (1H, d, J=7.8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com