Preparation method of ZSM-type molecular sieve without binding agent

A binder-free, molecular sieve technology, applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve the problem of hindering reactants, reducing the effective components of the catalyst per unit mass, and reducing the catalyst reactivity and other problems, to achieve the effect of improving crystallinity, reducing dosage, and high template index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0013] Weigh 100 grams of silicon-aluminum molar ratio SiO 2 / Al 2 o 3 20 ZSM-5 molecular sieve, 62.5 grams of 40% (weight) silica sol was added and mixed, extruded and dried at 120°C to obtain sample A-1.

[0014] Add 5 grams of tetrapropylammonium bromide, 10 grams of 1, a mixture of 6-hexamethylenediamine and 30 grams of distilled water in advance in the reactor, place 10 grams of sample A-1 in the reactor after being sealed above the porous stainless steel mesh Gas-solid phase treatment was carried out at 180°C for 24 hours, 72 hours, and 120 hours.

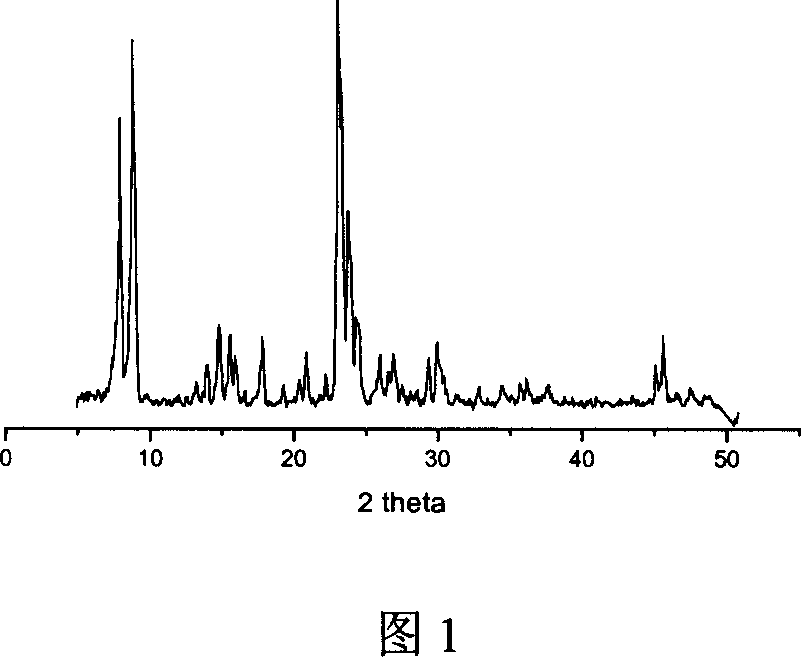

[0015] After the product was taken out, it was washed with distilled water, dried in the air and then calcined at 600°C in an air atmosphere. The XRD spectrum of the product processed for 24 hours shows that the crystallinity has increased at this time, indicating that new ZSM-5 molecular sieve crystals are generated; the crystallinity of the product after processing for 72 hours has been higher; the processing time is ext...

Embodiment 4~5

[0017] Weigh 100 grams of silicon-aluminum molar ratio SiO 2 / Al 2 o 3 100 ZSM-5 molecular sieve, 13 grams of 40% (weight) silica sol was added and mixed, extruded and dried at 120° C. to obtain sample B-1.

[0018] Add 2 grams of tetrapropylammonium bromide, 15 grams of 1,6-hexamethylenediamine and 30 grams of distilled water in advance in the reaction kettle, and place 10 grams of sample B-1 in the reaction kettle after being sealed above the porous stainless steel mesh Gas-solid phase treatment was carried out at 120°C for 72 hours and 120 hours.

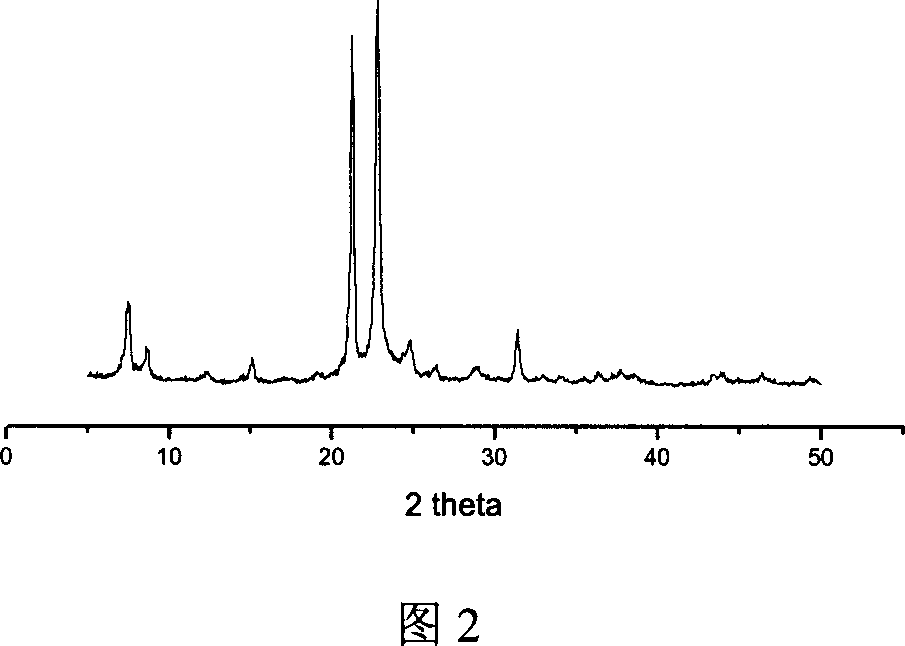

[0019] After the product was taken out, it was washed with distilled water, dried in the air and then calcined at 550°C in an air atmosphere. The XRD pattern of the product treated for 72 hours showed that the crystallinity of the product was already high; when the treatment time was extended to 120 hours, the crystallinity of the product did not continue to increase.

Embodiment 6~8

[0021] Weigh 100 grams of silicon-aluminum molar ratio SiO 2 / Al 2 o 3 600 ZSM-48 molecular sieve, mixed with 68 grams of water glass with a silica content of 25.9% (weight), extruded and dried at 120°C to obtain sample C-1.

[0022] Add 10 grams of tetrapropylammonium bromide, 5 grams of 1,6-hexamethylenediamine and 30 grams of distilled water in advance in the reaction kettle, and place 10 grams of sample C-1 in the reaction kettle after being sealed above the porous stainless steel mesh. Gas-solid phase treatment was carried out at 200°C for 24 hours, 72 hours, and 120 hours.

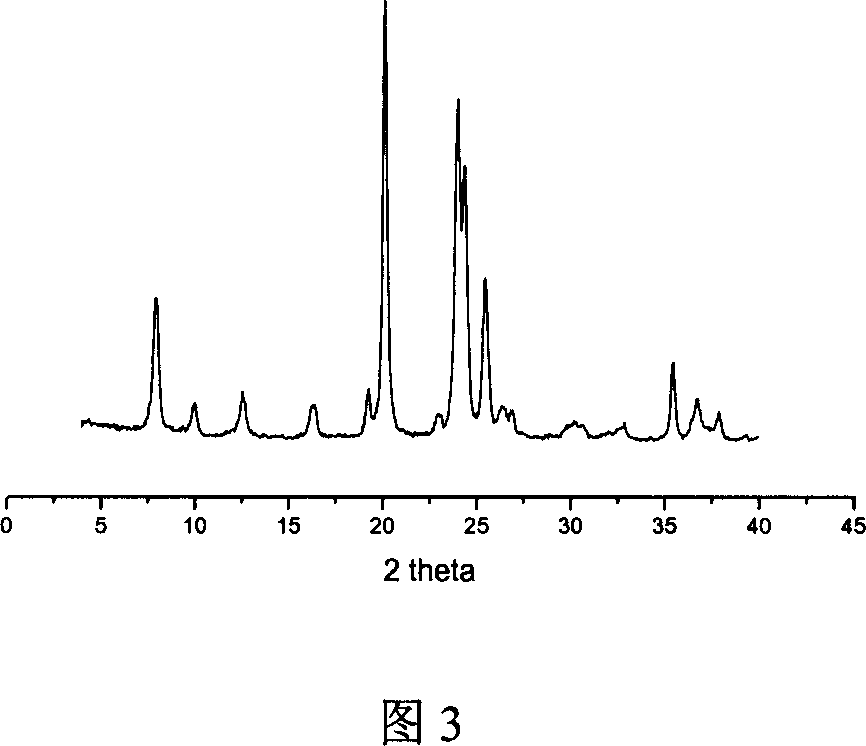

[0023] After the product was taken out, it was washed with distilled water, dried in the air and then calcined at 600°C in an air atmosphere. The XRD pattern of the product treated for 24 hours shows that the crystallinity is already high at this time; the crystallinity of the product does not continue to increase when the treatment time is extended to 72 hours and 120 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com