High selective catalyst

A high-selectivity, catalyst technology, applied in the direction of molecular sieve catalysts, physical/chemical process catalysts, organic chemistry, etc., can solve the problems of low selectivity of target products, low conversion rate of raw materials, etc., achieve high template index, improve specific surface, The effect of increasing crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

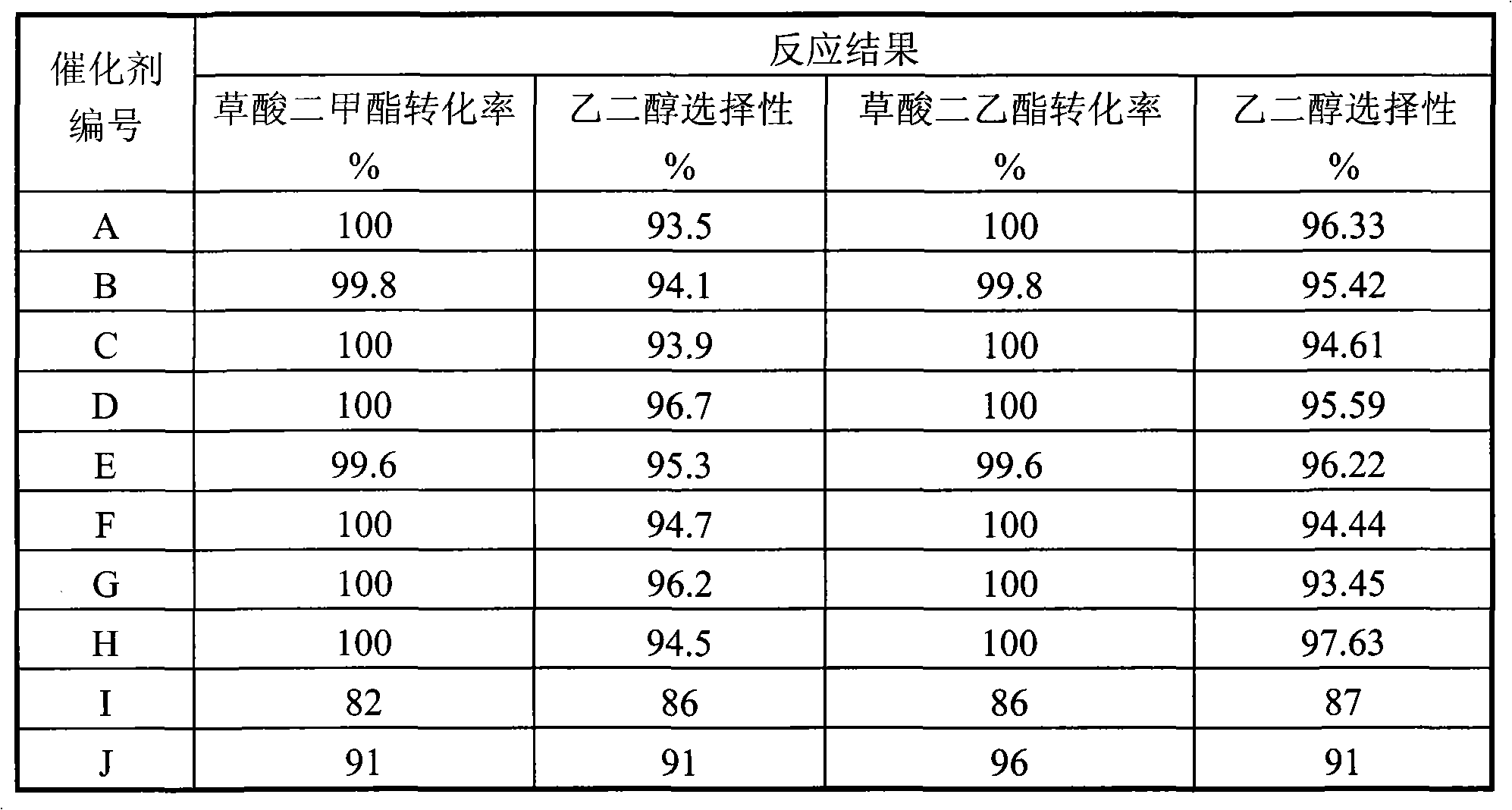

Examples

Embodiment 1

[0031] Weigh 120 grams of silicon-aluminum molar ratio SiO 2 / Al 2 o 350 ZSM-5 molecular sieve, 75 grams of 35% (weight) silica sol was added and mixed, extruded and dried at 110°C to obtain sample A-I.

[0032] Add 6 grams of tetrapropylammonium bromide, 12 grams of 1,6-hexamethylenediamine and 36 grams of distilled water in advance in the reaction kettle, and place 12 grams of sample A-I in the reaction kettle after being sealed above the porous stainless steel mesh at 180 The gas-solid phase treatment was carried out at ℃ for 160 hours. After the product was taken out, it was washed with distilled water, and after drying, it was roasted at 550°C in an air atmosphere to obtain a binder-free ZSM-5 molecular sieve carrier A with a specific surface of 450 square meters per gram and a molar ratio of silicon to aluminum of SiO 2 / Al 2 o 3 for 50.

[0033] Weigh 50 grams of the binder-free ZSM-5 molecular sieve carrier A made above, and prepare the catalyst according to the ...

Embodiment 2

[0035] Weigh 150 grams of silicon-aluminum molar ratio SiO 2 / Al 2 o 3 150 ZSM-5 molecular sieve, after adding 20 grams of 30% (weight) silica sol and mixing, extruded, dried at 130° C. to obtain sample B-I.

[0036] Add 3 gram tetrapropyl ammonium bromide, 15 gram 1, the mixture of 6-hexanediamine and 40 gram distilled water in advance in reaction kettle, place 15 gram samples B-I in the reaction kettle after sealing above the porous stainless steel mesh at 140 The gas-solid phase treatment was carried out at ℃ for 140 hours. After the product was taken out, it was washed with distilled water, dried, and then baked at 550°C in an air atmosphere to obtain a binder-free ZSM-5 molecular sieve carrier B with a specific surface of 500 square meters per gram and a silicon-aluminum molar ratio of SiO 2 / Al 2 o 3 for 150.

[0037] Take by weighing 50 grams of the binder-free ZSM-5 molecular sieve carrier B made above, prepare the catalyst by 38% Cu+0.1%V+0.05%La+0.2%Zr / ZSM-5 co...

Embodiment 3

[0039] Weigh 110 grams of silicon-aluminum molar ratio SiO 2 / Al 2 o 3 300 ZSM-48 molecular sieve, after adding 75 grams of water glass with a silicon oxide content of 30% (by weight) and mixing, extruding and drying at 130 ° C to obtain sample C-I.

[0040] 12 grams of tetrapropylammonium bromide, 5 grams of 1,6-hexanediamine and 35 grams of distilled water were added in advance in the reactor, and 12 grams of sample C-I was placed in the reactor after being sealed above the porous stainless steel mesh at 2110 The gas-solid phase treatment was carried out at ℃ for 180 hours. After the product was taken out, it was washed with distilled water, dried and roasted at 580°C in an air atmosphere to obtain a binder-free ZSM-48 molecular sieve carrier C with a specific surface of 560 square meters per gram and a molar ratio of silicon to aluminum of SiO 2 / Al 2 o 3 for 300.

[0041] Take by weighing 100 grams of the above-mentioned binder-free ZSM-48 molecular sieve carrier C w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com