Deburring method and apparatus based on laser shock wave

A shock wave and laser technology, which is applied in the field of metal cutting burr removal and inner cavity cutting burr removal, can solve problems such as difficult to remove burrs, restrictions, pressure failure, etc., to achieve maximum flexibility, delay attenuation, anti-fatigue performance and Effect of Stress Corrosion Resistance Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

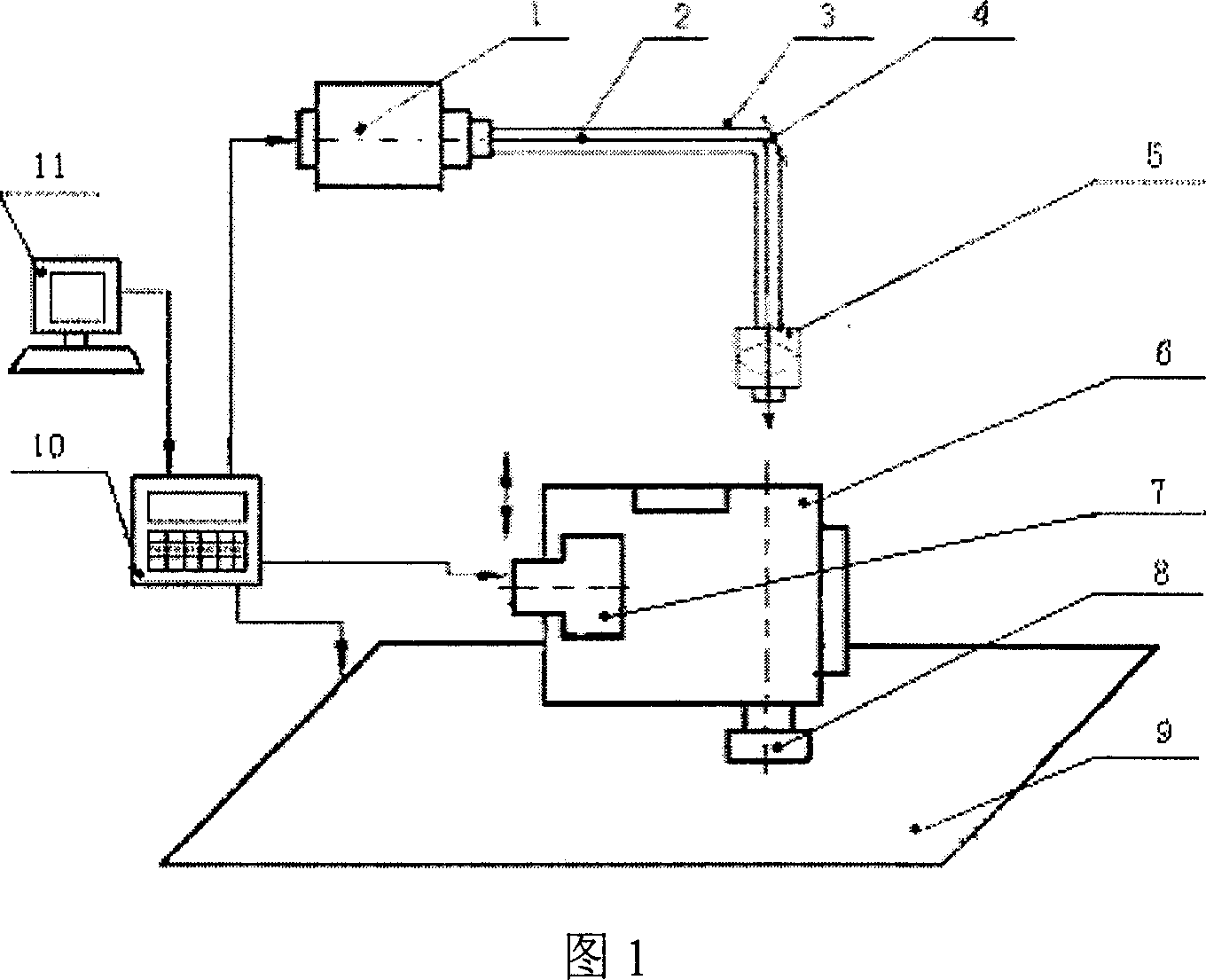

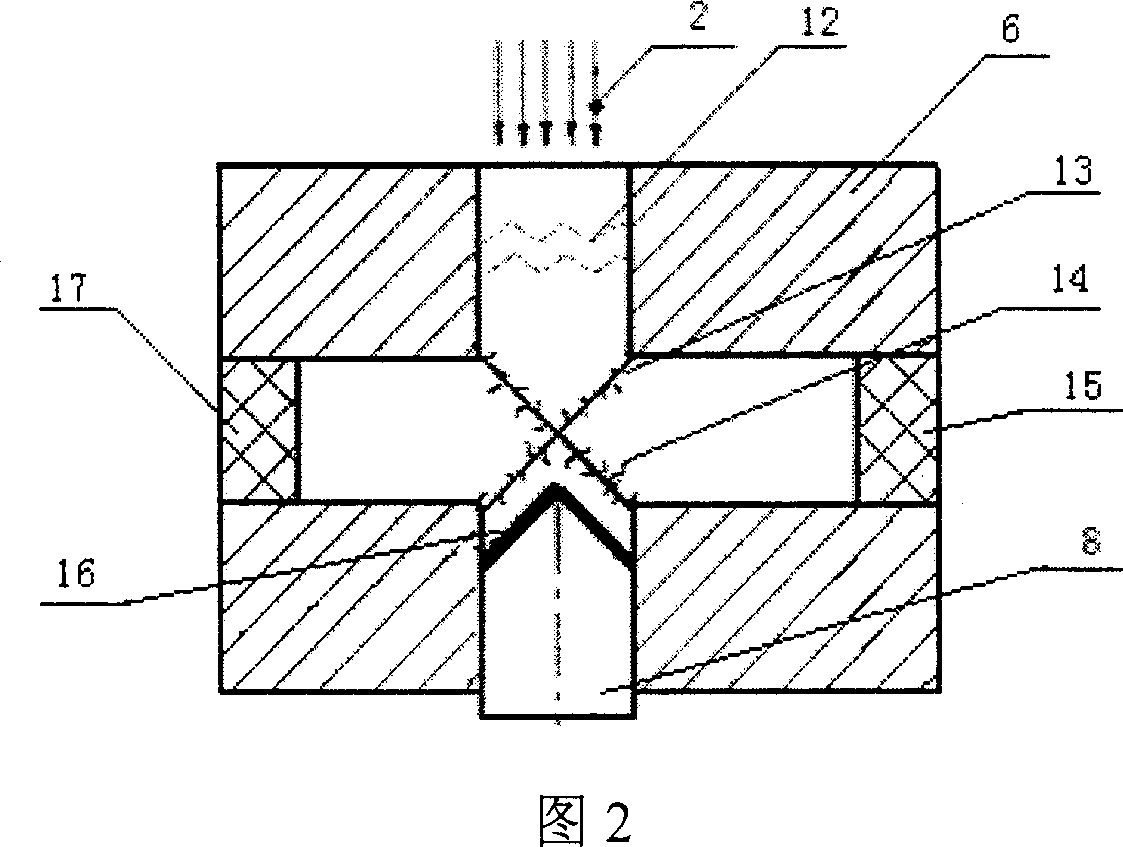

[0016] The device mainly includes a laser generator (1), a light guide system, a workpiece fixture system and a control system. Wherein the light guide system includes a light guide pipe (3), a total reflection mirror (4) and an impact head (5), and the workpiece fixture system includes a constraining layer (water) (12), a plug (15), and an absorbing layer (black paint) (16), reflection cone (8), plug (17), workpiece (6), fixture (7), workbench (9) form, and control system comprises computer (11) and controller (10).

[0017] The laser generator (1) emits optimized laser pulses (2), the beam modes of the laser pulses (2) can be fundamental mode, multi-mode and other modes, which are regulated and controlled by the controller (10). The laser beam (2) produced by the laser generator (1) is irradiated on the reflection cone ( 8) On the energy absorbing layer (16) of the surface. There is a focusing lens in the impact head (5), and the size of the light spot can be changed by ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com