Environmentally friendly coating compositions and coated articles and coating methods and process and assemblages thereof

A composition, mixture technology, applied in the field of environmentally friendly coating compositions for coating metal objects, objects coated therewith, and coating, process and combination systems thereof, capable of solving problems such as generating problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

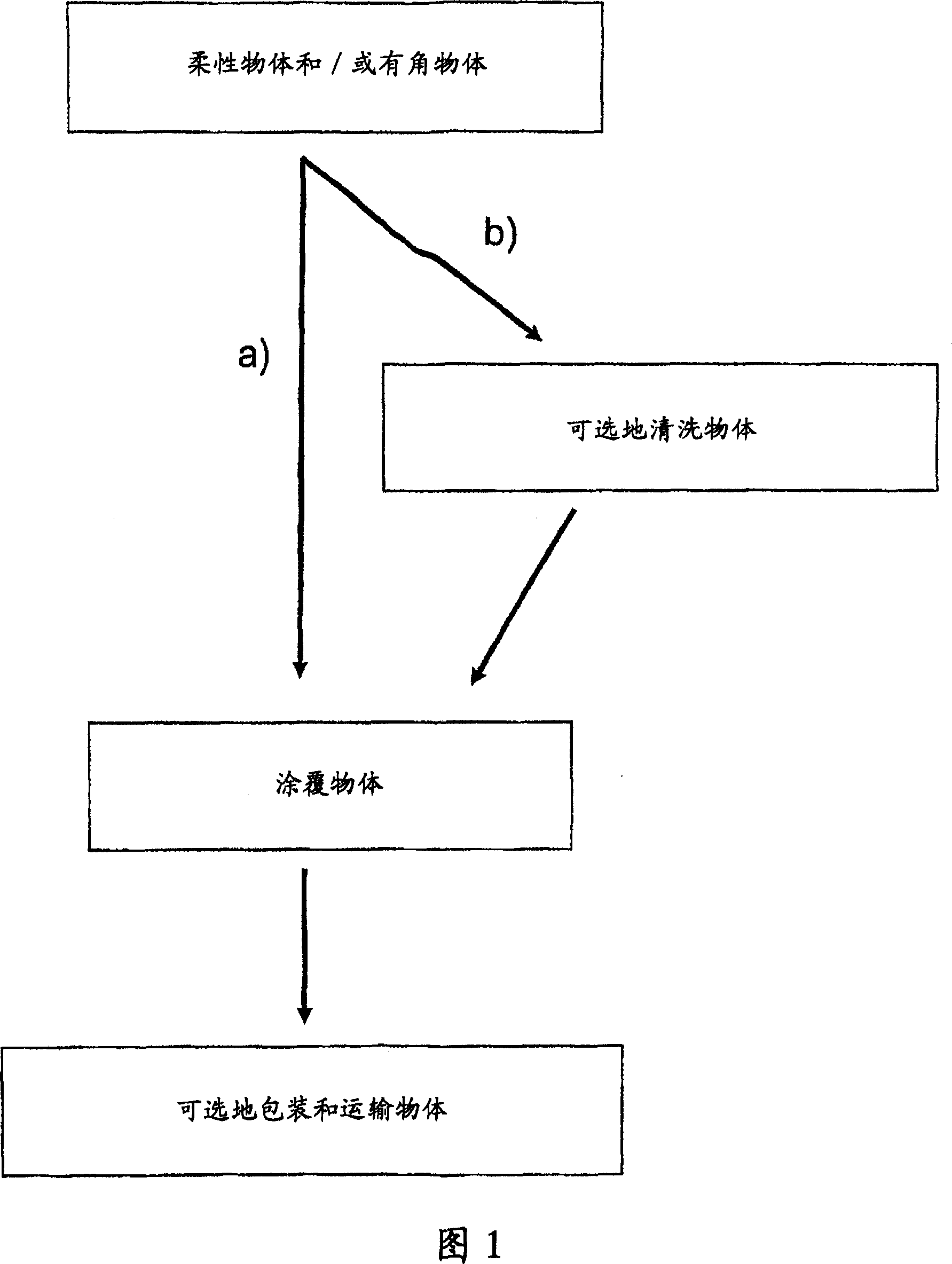

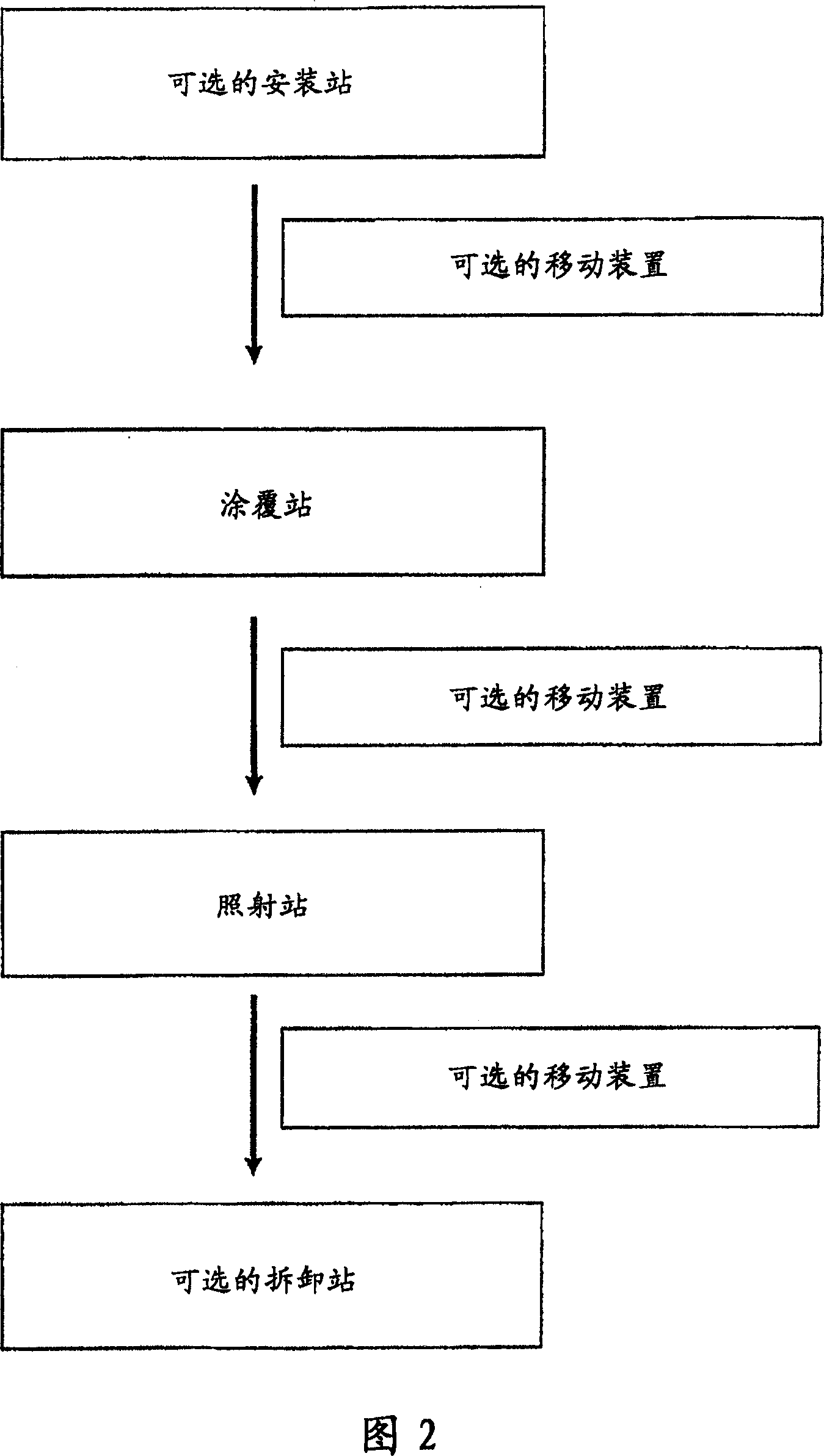

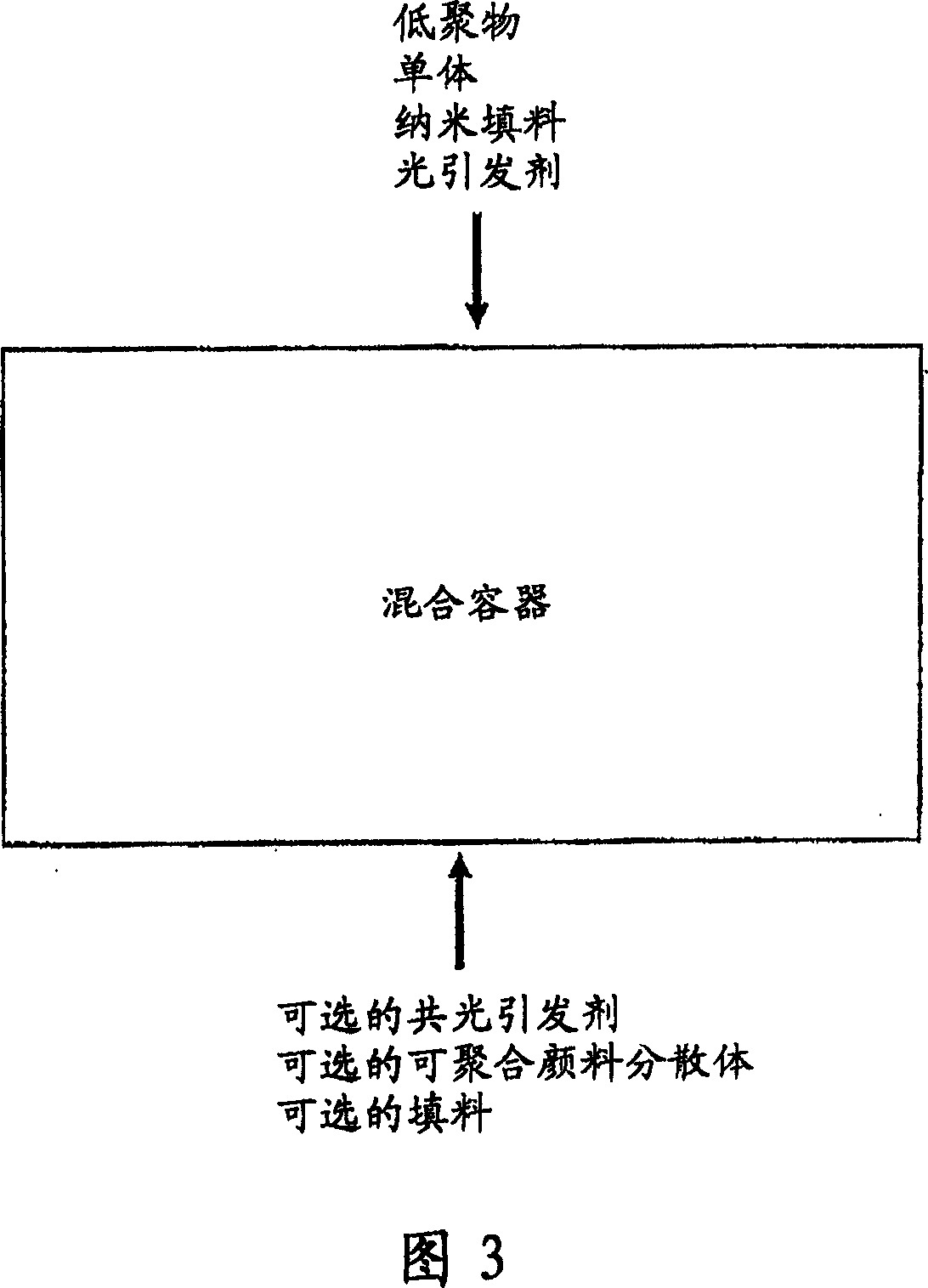

Method used

Image

Examples

Embodiment 1

[0168] Example 1: Formulation for a clear coating composition.

[0169] Embodiments for clear coating compositions were prepared by mixing the following components with a screw mixer to produce a flexible coating with excellent abrasion, scratch, corrosion and adhesion properties: 25.683% Aliphatic Polyurethane Triacrylate (EBECRYL(R) 264 from UCBSurface Specialties, Brussels, Belgium), 18.032% 2-phenoxyethyl acrylate, 26.229% isobornyl acrylate, 8.743% methacrylate ester derivative adhesion promoter (EBECRYL ® 168 from UCB Surface Specialties, Brussels, Belgium), 14.210% propoxylated glyceryl triacrylate-nanosilica (Nanocryl® C-155, formerly known as Nanocryl® XP 21 0953 from hansechemie AG, Geesthacht, Germany), 5.464% DARACUR(R) 1173 (from Ciba Specialty Chemicals 540 White Plains Road, Tarrytown, New York, U.S.A.), and ESACURE(R) KTO-46 (from Lamberti, S.p.A., Gallarate (VA), Italy). The ingredients are thoroughly mixed with a screw mixer until a homogeneous composition i...

Embodiment 2

[0170] Example 2: Formulation for black compositions.

[0171] An embodiment of a colored composition to produce a flexible coating with excellent abrasion, scratch, corrosion and adhesion properties was prepared as follows: 94.43% of the clearcoat composition of Example 1 was mixed with a screw mixer, 3.60% of carbon black bonded to modified acrylic acid (solid pigment dispersion, PC 9317 from Elementis, Staines, UK) and 2.06% of organically surface-treated synthetic amorphous silica (SYLOID® RAD 221 from Grace Davison division of WR Grace & Co., Columbia, MD, U.S.A.) was mixed into the above 94.43% clearcoat composition. These additives are dispersed throughout the clearcoat with a screw mixer until a uniform black coating composition is formed, which can be applied by HVLP and cured with UV light.

Embodiment 3

[0172] Example 3: Procedures to Form a Clear Flexible Coating with Improved Abrasion, Scratch Resistance, Corrosion Resistance and Adhesion.

[0173] Another embodiment is a step for preparing a clear coating composition. The components of the coating composition are mixed under air because the presence of oxygen prevents premature polymerization. It is desirable to keep exposure light to a minimum and in particular sodium vapor lamps should be avoided. However, there is an option to use darkroom lighting. Elements used in the manufacture of the coating composition that come into contact with the monomer and coating mixture, such as mixing vessels and mixing blades, should be made of stainless steel or plastic, preferably polyethylene or polypropylene. Polystyrene and PVC should be avoided as they will be dissolved by the monomer and paint mixture. In addition, contact of monomers and coating mixtures with mild steel, copper alloys, acids, bases and oxidizing agents should ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com