Aromatic polyamide reverse osmose composite membrane

A technology of reverse osmosis composite membrane and aromatic polyamide, applied in the field of water separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

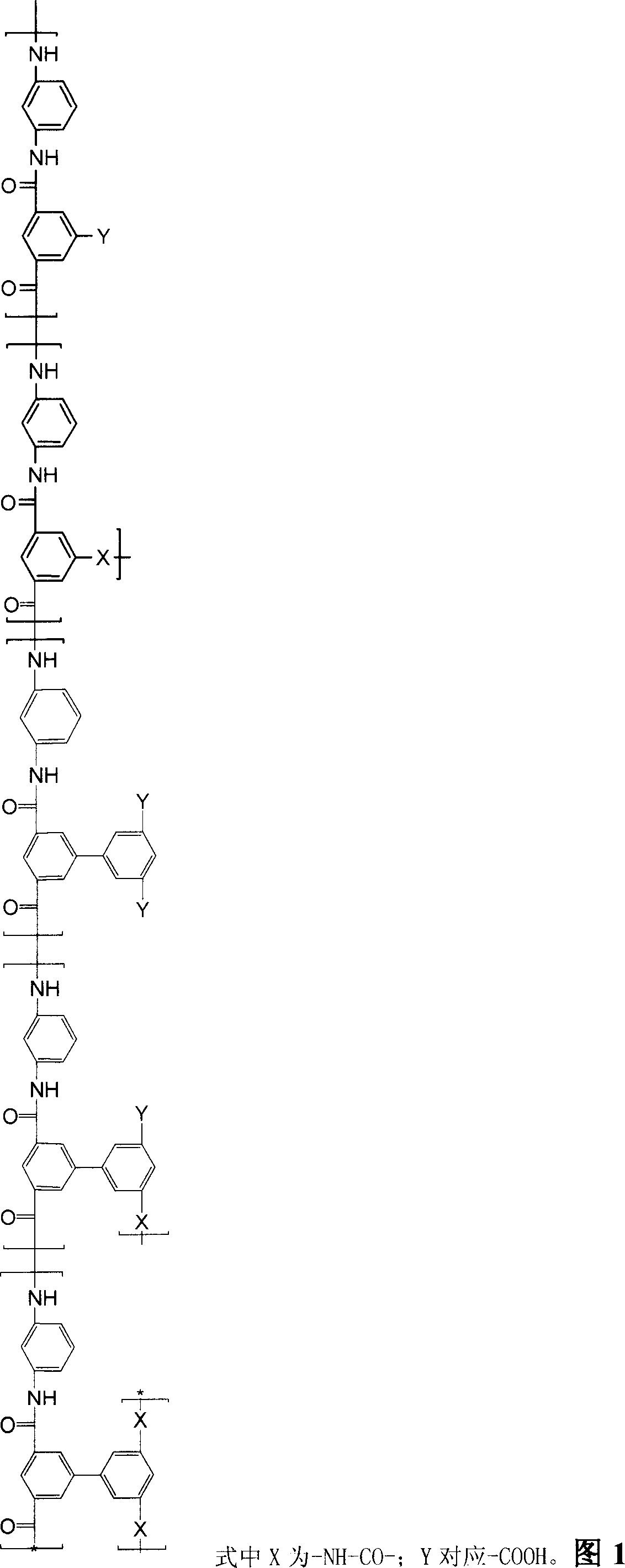

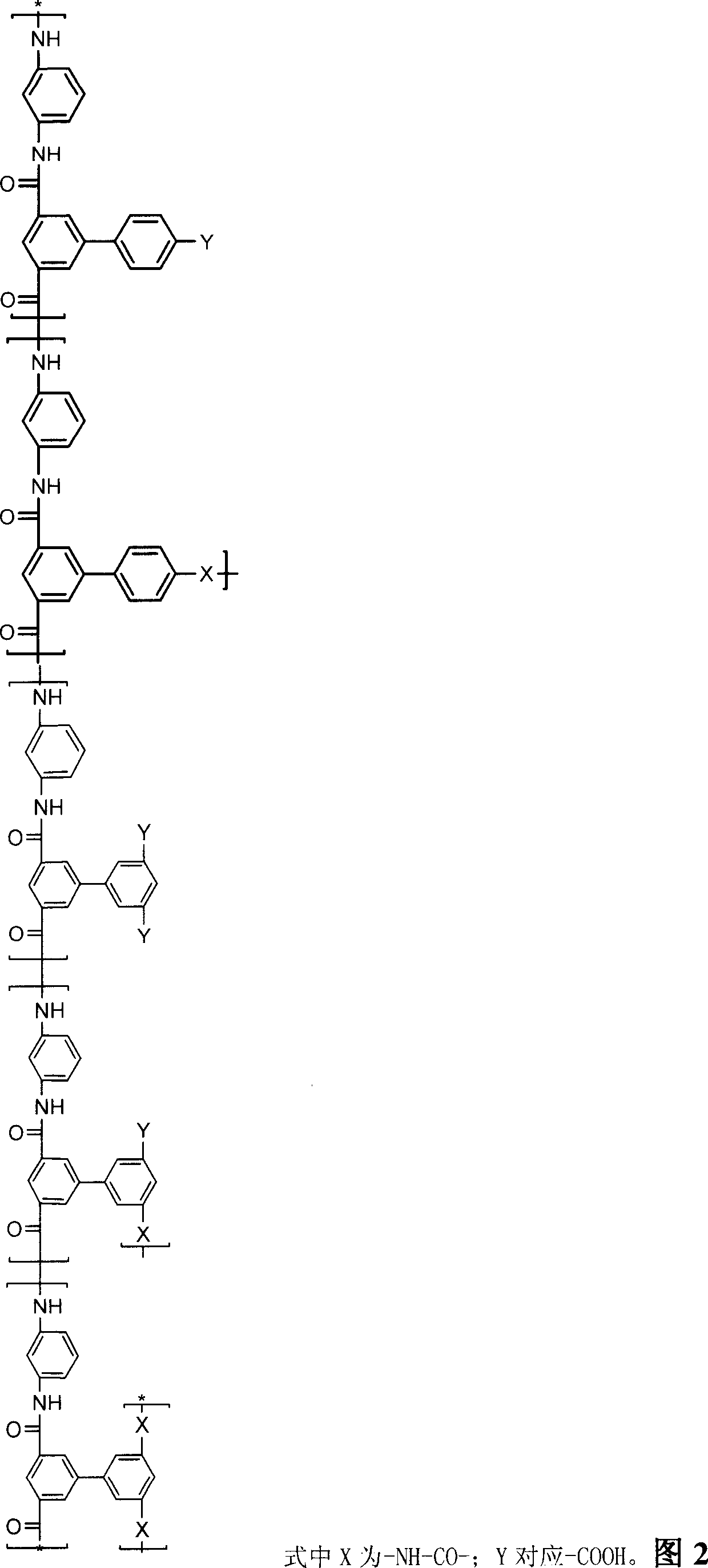

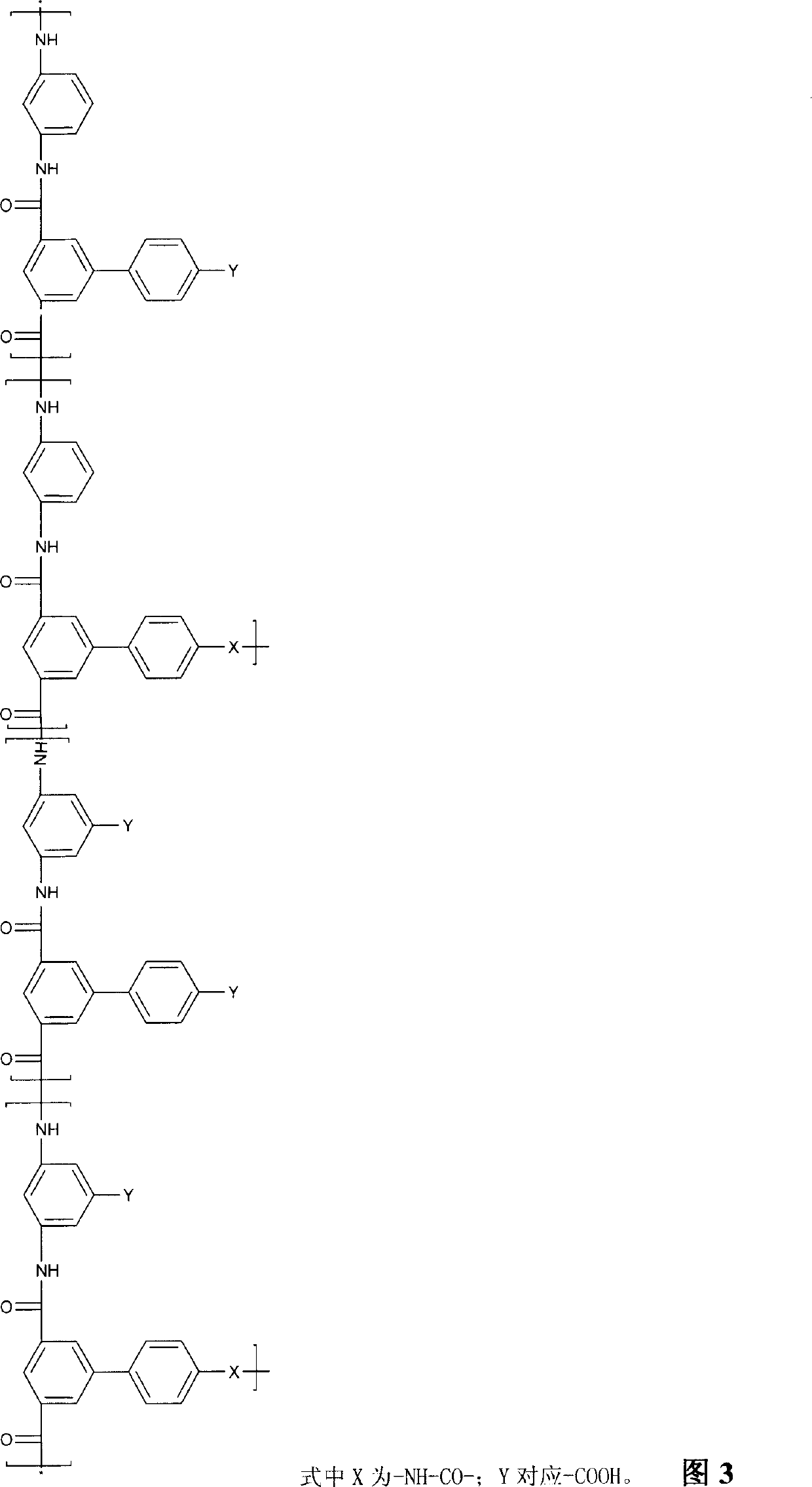

Image

Examples

Embodiment 1

[0066] 99.0g of polysulfone with a mass concentration of 16.5%, 81.0g of ethylene glycol monomethyl ether with a mass concentration of 13.5%, and 0.18g of sodium dodecylsulfonate with a mass concentration of 0.03% were dissolved in 419.8gN,N-di In methyl formamide, it is coated on the polyester non-woven fabric, and then immersed in water to remove the good solvent to obtain a support layer with a molecular weight cut off (MWCO) of about 20,000, and then stored in deionized water for later use.

[0067] Cover the surface of the wet polysulfone support membrane with an aqueous solution of m-phenylenediamine with a mass volume concentration (g / ml) of 2% for 3 minutes, then pour off the excess amine solution, dry in the air for 6 minutes, and then mix with 3,4 ', 5-biphenyltrichloride mass volume concentration (g / ml) is 0.05% cyclohexane solution single-sided contact to carry out interfacial polymerization reaction for 20 seconds. It is then subjected to the first heat treatment:...

Embodiment 2

[0069] Example 2. A cyclohexane solution with a mass volume concentration (g / ml) of 0.10% of 3,4',5-biphenyltrichloride was used, and the rest of the conditions were the same as in Example 1. The test result is: flux 33.1l / m 2 .h, the desalination rate is 99.1%.

Embodiment 3

[0070] Example 3. A cyclohexane solution with a mass volume concentration (g / ml) of 0.15% of 3,4',5-biphenyltrichloride was used, and the rest of the conditions were the same as in Example 1. The test result is: flux 23.8l / m 2 .h, the desalination rate is 97.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com