Purifying robot

A technology for purifying robots and machine bases. It is applied in the direction of manipulators, claw arms, and manufacturing tools. It can solve the problems of limited range of motion and working space, and achieve the effect of simple and novel mechanism, easy production and maintenance, and large working space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

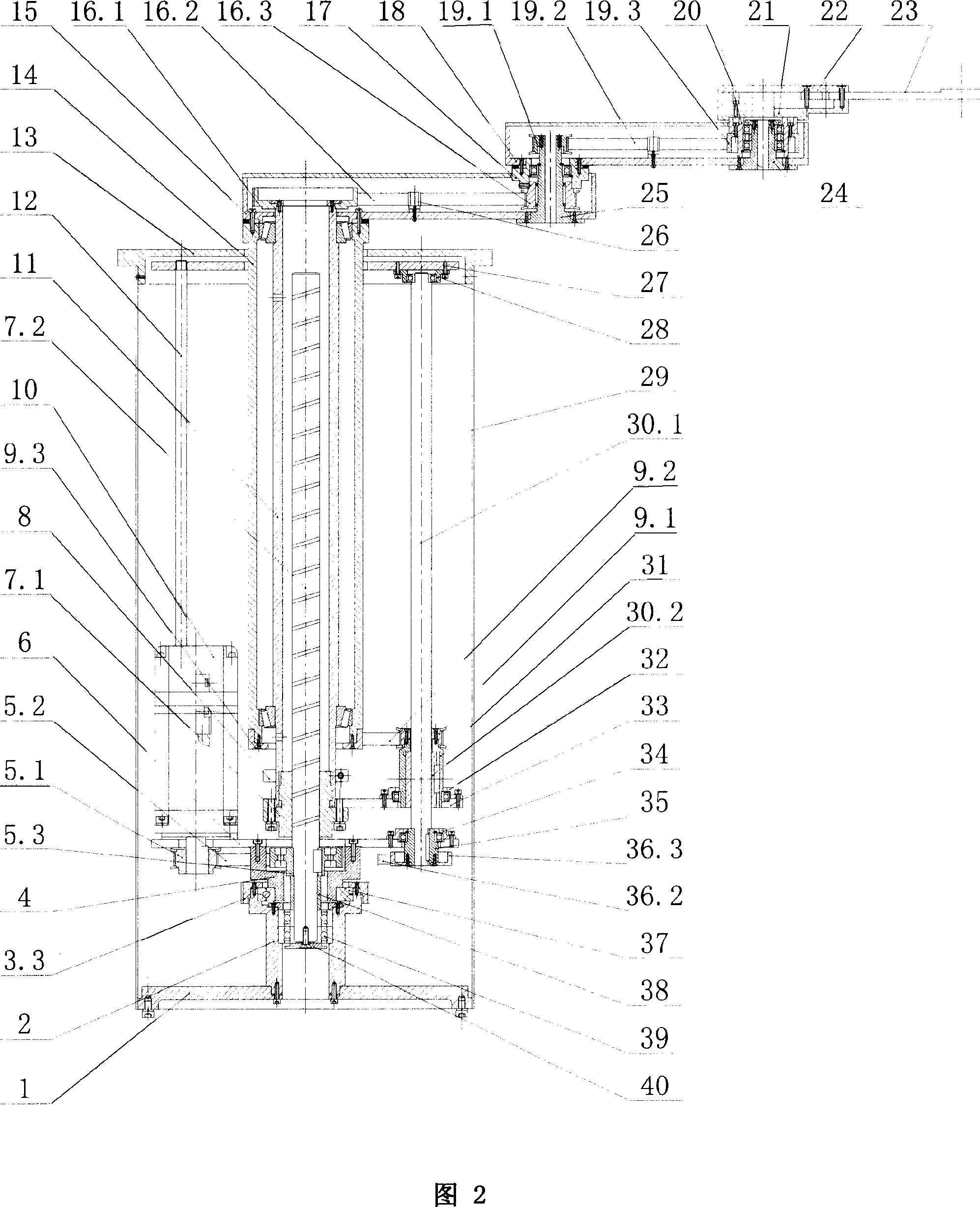

[0030] The present invention is described in more detail below in conjunction with accompanying drawing:

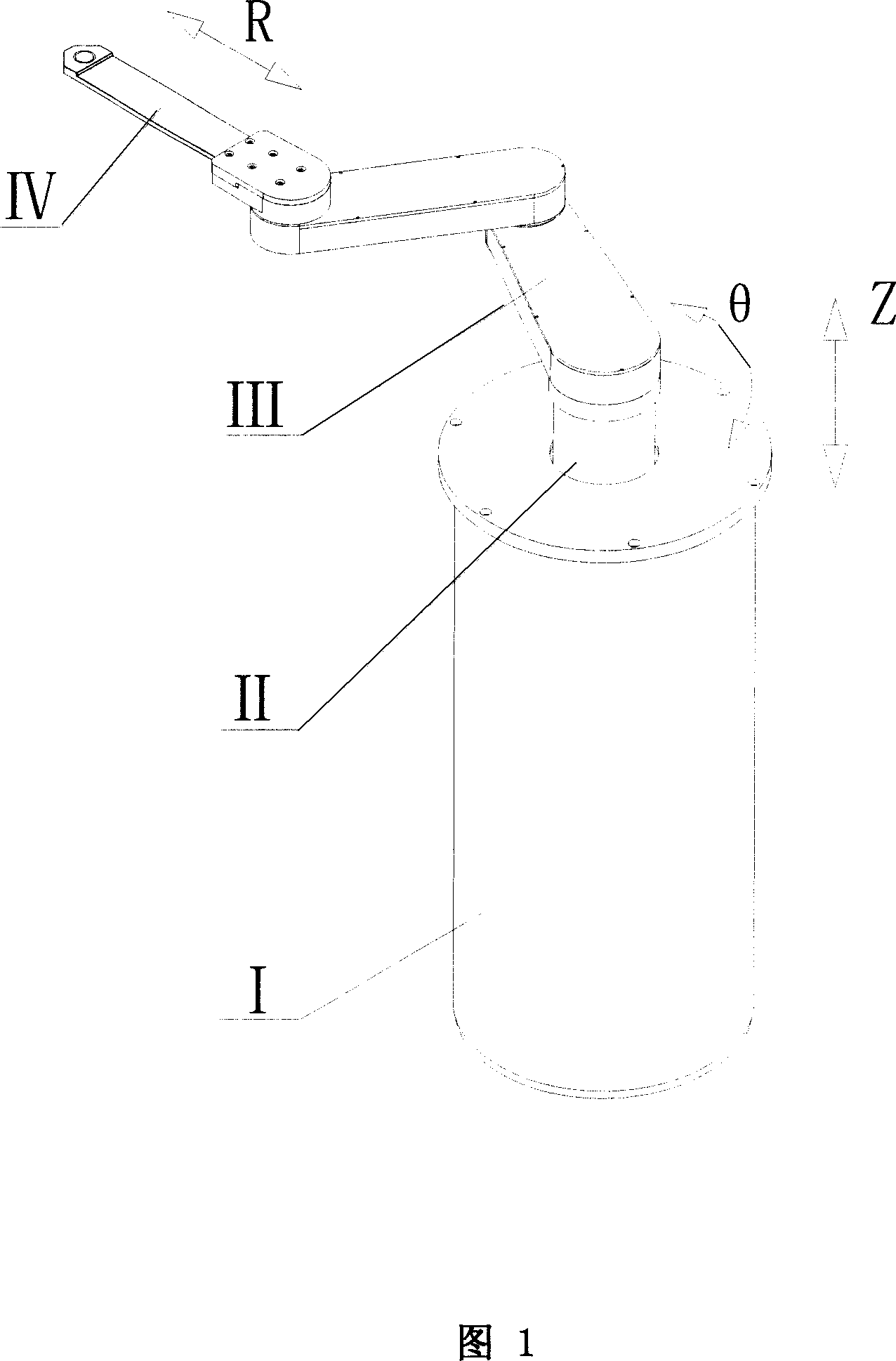

[0031] The cleaning robot of the present invention is composed of a base I, an R-direction linear expansion mechanism III, a θ-direction rotation mechanism II, a Z-direction lifting mechanism II and an end effector IV.

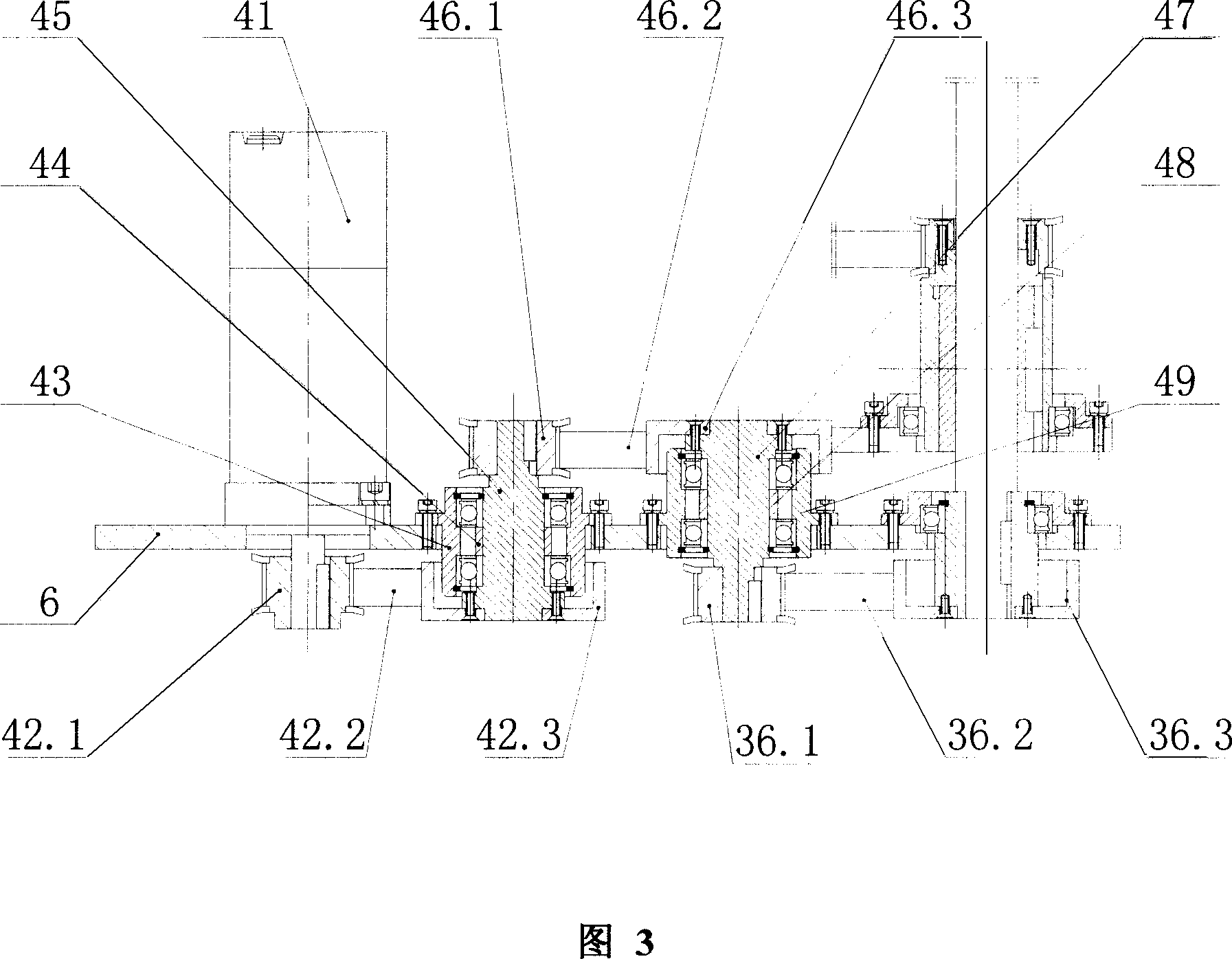

[0032] R-direction movement: the rotating motor 41 drives the ball spline shaft 30.1 to rotate through 3 groups (42.1, 42.2, 42.3; 46.1, 46.2, 46.3; 36.1, 36.2, 36.3) synchronous toothed belt wheel reduction mechanism and the spline bushing 35, The ball spline shaft 30.1 transmits torque through the spline nut 30.2, and then the spline nut 30.2 drives the small synchronous toothed pulley 9.1 connected to it to rotate through the nut jacket 31, and the synchronous toothed belt 9.2 and the large synchronous toothed pulley 9.3 Further drive the outer sleeve 15 and the large arm body 15 fixedly connected with it to rotate around the central axis of the base. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com