Steel wire one-line luminosity modified treatment method and production line

A quenching and tempering treatment and production line technology, applied in heat treatment furnaces, heat treatment equipment, heat treatment process control and other directions, can solve problems such as poor stability, complex process, workpiece distortion, etc., achieve uniform performance and structure, overcome internal and external unevenness, performance and tissue stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

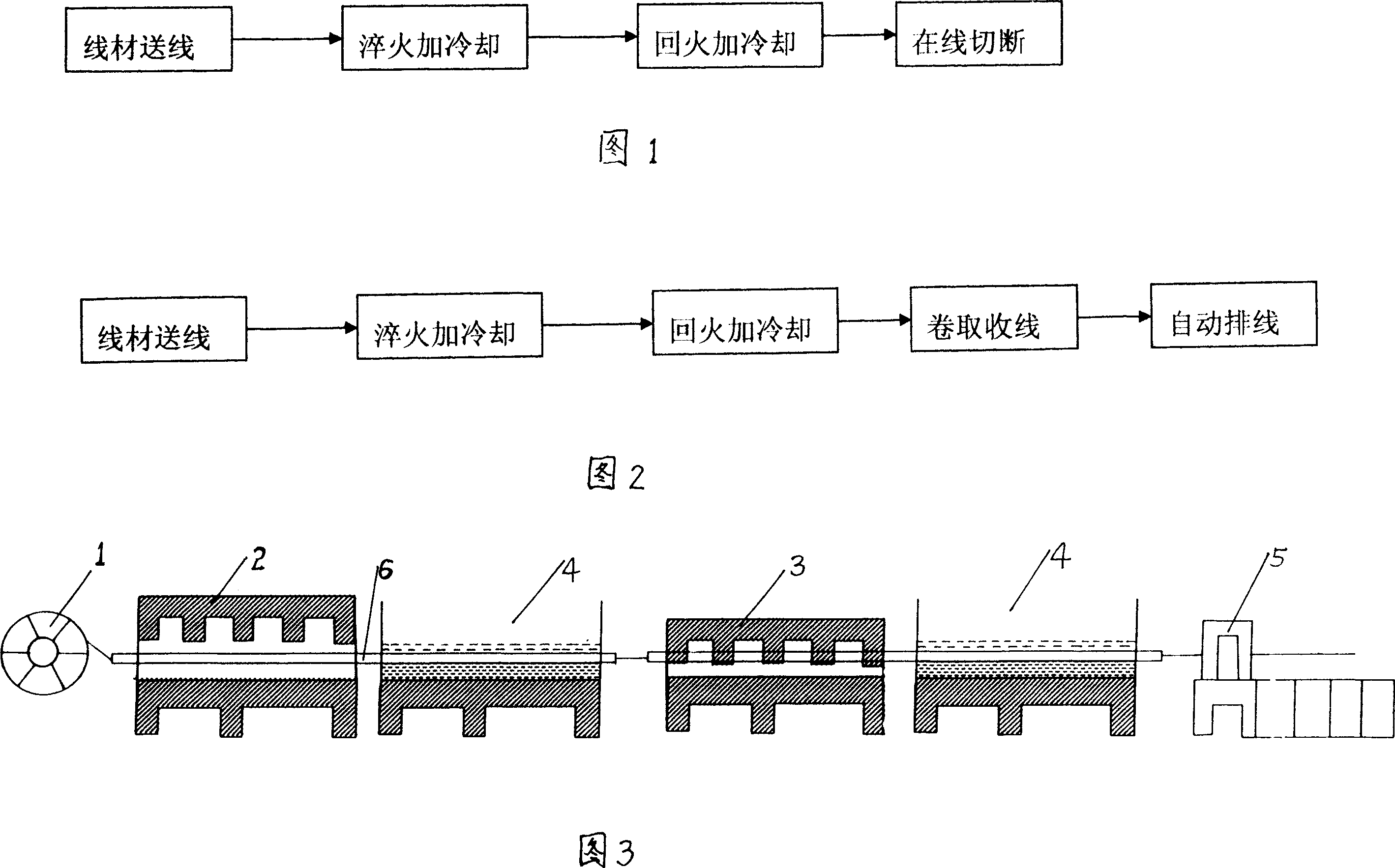

[0021] As shown in Figure 1, the steel quenching and tempering process for molds: the steel wire is released through the pay-off frame, and the linear continuous routing is first quenched through the quenching furnace. The quenching temperature is 1100 ° C, and the quenching cooling temperature is 40 ° C. The wire is tempered through a tempering furnace, the tempering temperature is 650°C, the tempering cooling temperature is 20°C, and then the material is discharged and cut into the required length on the wire. Both quenching and tempering are carried out under nitrogen atmosphere.

Embodiment 2

[0023] As shown in Figure 1, the steel quenching and tempering process for miniature shafts: the steel wire is released through the pay-off frame, and the linear continuous line is first quenched through the quenching furnace. The quenching temperature is 1070 ° C, and the quenching cooling temperature is 45 ° C. The wires are tempered through a tempering furnace, the tempering temperature is 600°C, the tempering cooling temperature is 25°C, and then the material is discharged and cut into required lengths online. Both quenching and tempering are carried out under nitrogen atmosphere.

Embodiment 3

[0025] The quenching and tempering treatment process of piston ring wire material as shown in Figure 2: the steel wire is released through the pay-off frame, and the linear continuous wire is first quenched through the quenching furnace. The quenching temperature is 1100 ° C, and the quenching cooling temperature is 48 ° C. The wire is tempered through the tempering furnace, the tempering temperature is 630°C, the tempering cooling temperature is 28°C, and then the material is discharged, and the wire is automatically arranged after winding and winding. Both quenching and tempering are carried out under nitrogen atmosphere.

[0026] The equipment adopted in the above-mentioned embodiments all includes a wire-feeding device 1, a quenching furnace 2 and a tempering furnace 3, and the quenching furnace and the tempering furnace are dynamically connected to a tubular continuous heat treatment furnace whose length ratio of two furnaces is 1: 2.2-3.5. Both furnace and tempering furna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com