Process for removing chloride fromiznc electrolytic solution by using silver hydroxide

A technology of electrolysis of silver hydroxide and zinc, which is applied in the direction of photographic process, photographic auxiliary process, process efficiency improvement, etc. It can solve the problems of difficult process conditions, low chlorine removal efficiency, high operating cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

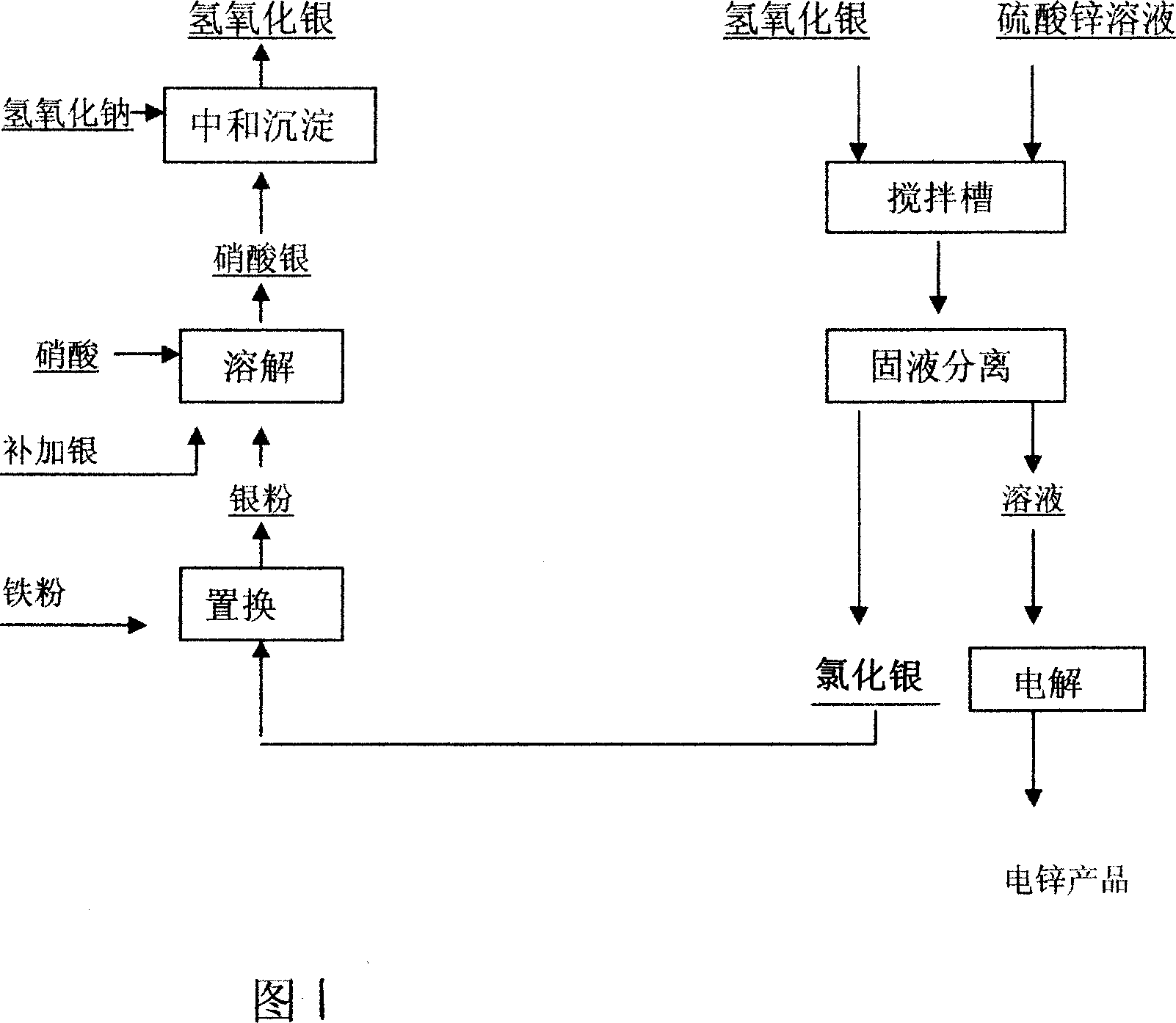

[0015] After the zinc sulfate leaching solution containing chloride ions is purified by the conventional three-stage zinc powder method, it is put into the 50m of the dechlorination workshop. 3 In the stirred tank, analyze the chlorine content of the solution, according to the reaction formula AgOH+Cl - =AgCl↓+OH - Calculate and add a certain amount of silver hydroxide, and after stirring for 30 minutes, take a sample to analyze the residual chlorine content in the solution, control the residual chlorine content of the solution in the range of 50-200 mg / liter, and then use the solution with 25m 2 The filter press is used to filter the solution, and the solution is sent to the electrolytic workshop to deposit zinc. The silver chloride slag obtained by filtering the filter press adopts a mature conventional method, namely: iron powder is replaced to obtain silver powder, silver powder is added with nitric acid to obtain silver nitrate, silver nitrate is added with sodium hydrox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com