Tantalum powder, and solid electrolyte capacitor using it

A solid electrolysis and capacitor technology, applied in the direction of electrolytic capacitors, capacitors, circuits, etc., can solve the problems of less leakage current and large electrostatic capacity, and achieve the effect of less leakage current, large electrostatic capacity, and reduced leakage current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

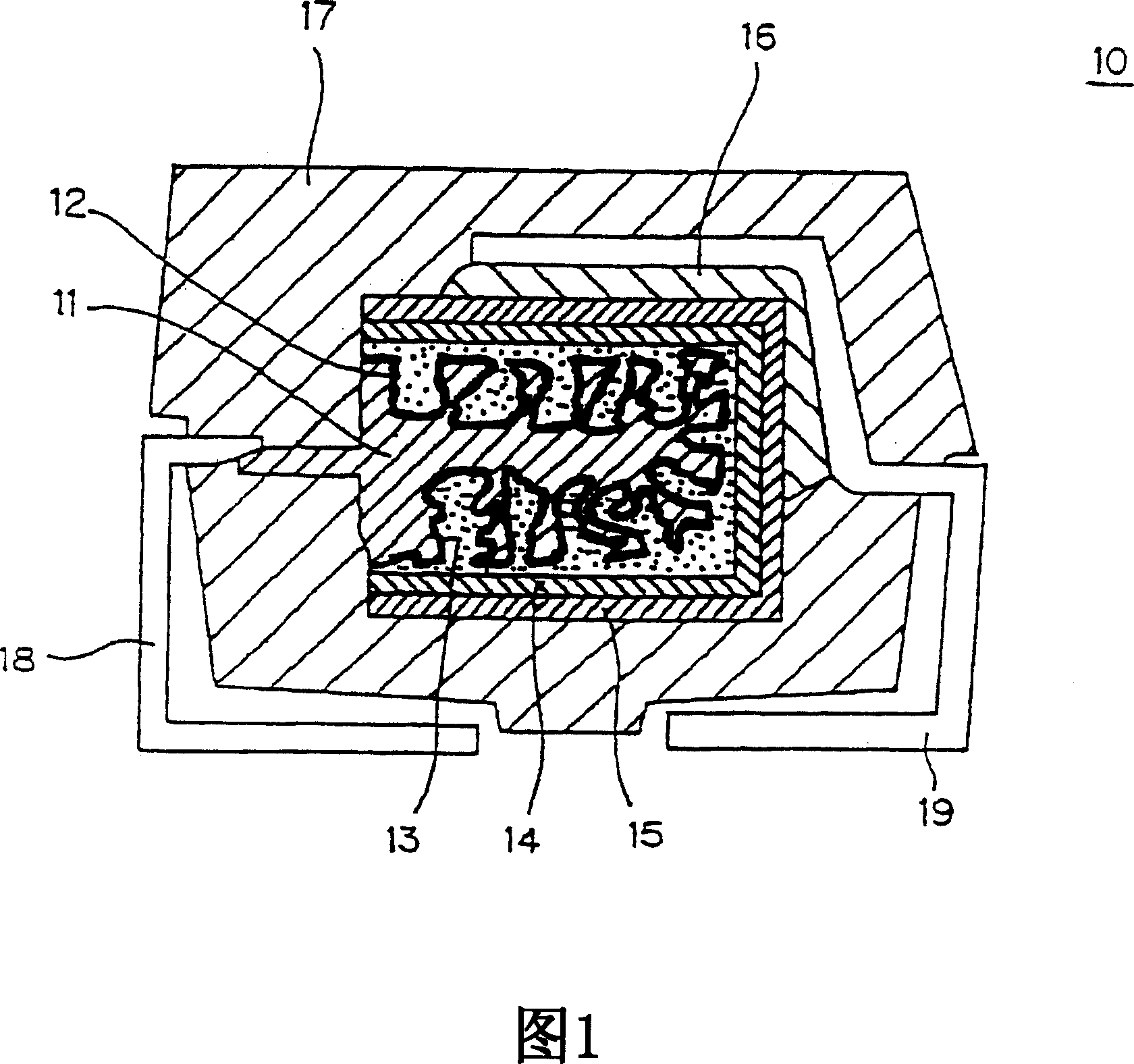

Image

Examples

Embodiment 1

[0057] Argon was supplied as an electrode working gas (electrode working gas) at 20 NL (Normal Litter) / min in a DC plasma CVD apparatus with a power supply of 20 kW, and a plasma arc was generated under atmospheric pressure. In this plasma arc, tantalum pentachloride gas vaporized at 350°C (15 g / min in terms of the weight of tantalum pentachloride) is mixed with argon at 10 NL / min and hydrogen gas for reduction 80NL / min, introduced into the plasma arc, and carried out gas phase hydrogen reduction reaction to obtain tantalum powder.

[0058] Put 10 g of the tantalum powder into the heating furnace, raise the temperature to the processing temperature of 300° C. at a rate of 10° C. / min in a mixed gas flow of argon 5 NL / min and nitrogen 1 NL / min, and keep it for 30 minutes. Then, it was cooled to room temperature under argon 5 NL / min flow. For this tantalum powder, the hydrogen content and the nitrogen content were measured using a thermal conductivity gas analyzer, and the speci...

Embodiment 2~4

[0060] (Examples 2-4), (Comparative Examples 1-2)

[0061]The tantalum powder obtained by the gas-phase hydrogen reduction method in Example 1 is processed under the mixed gas flow of argon 5NL / min and nitrogen 1NL / min, and the processing temperature at this time is changed to the temperature shown in Table 1. In addition, the other Operate in the same way as in Example 1. It should be noted that the term "untreated" in Comparative Example 2 means that the tantalum powder was not heat-treated in a mixed gas flow of 5 NL / min of argon and 1 NL / min of nitrogen. The results are shown in Table 1.

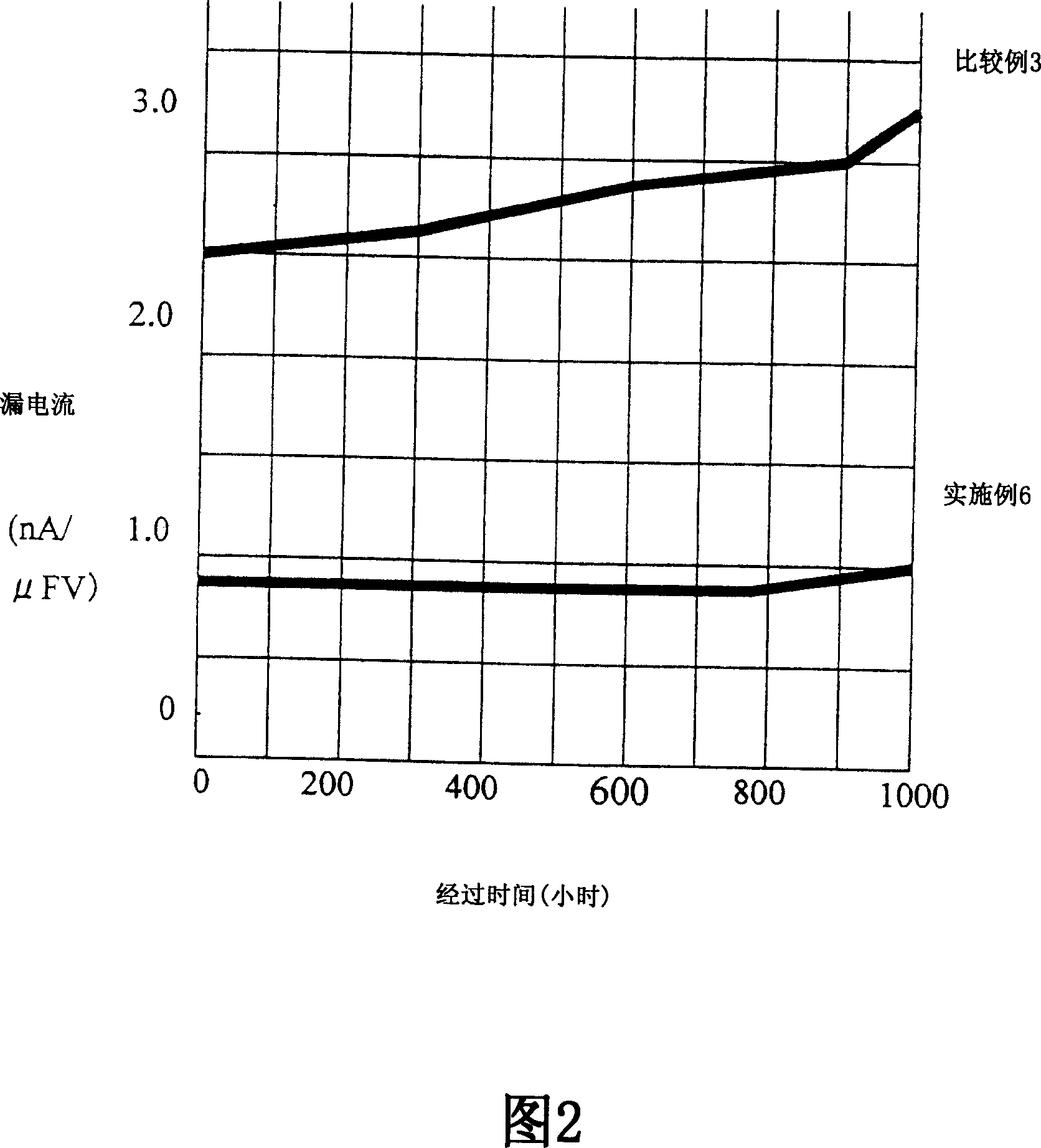

[0062] In Examples 1 and 2 to 4 within the scope of the present invention, the leakage current is 0.5 nA / μFV or less, and the electrostatic capacity is 160,000 μFV / g or more. However, in Comparative Examples 1 and 2, since the ratio of the hydrogen content to the specific surface area is outside the scope of the present invention, the leakage current is large and the electrostatic capa...

Embodiment 5

[0064] 20 NL / min of argon as an electrode gas was supplied to a DC plasma CVD apparatus with a power of 20 kW, and a plasma arc was generated under atmospheric pressure. In this plasma arc, a mixed gas formed by mixing tantalum pentachloride gas (10 g / min as tantalum pentachloride powder) gasified at 350°C with argon 10 NL / min and hydrogen gas 100 NL / min is introduced. In the plasma arc, gas-phase hydrogen reduction reaction is carried out to obtain tantalum powder.

[0065] Put 10 g of the tantalum powder into the heating furnace, raise the temperature to the processing temperature of 200° C. at a rate of 10° C. / min in a mixed gas flow of argon 5 NL / min and nitrogen 1 NL / min, and keep it for 30 minutes. Then, it was cooled to room temperature under argon 5 NL / min flow. For this tantalum powder, the hydrogen content and the nitrogen content were measured using a thermal conductivity gas analyzer, and the specific surface area was measured by the BET method. As a result, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com