Nonaqueous electrolyte solution and lithium secondary battery using same

An electrolyte, non-aqueous technology, applied in the field of lithium secondary batteries and non-aqueous electrolytes, can solve the problems of not mentioning battery characteristics, battery characteristics decline, continuous charging characteristics decline, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

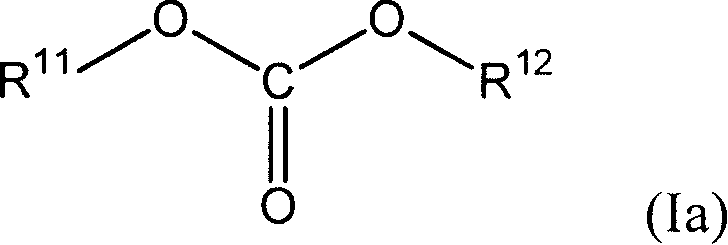

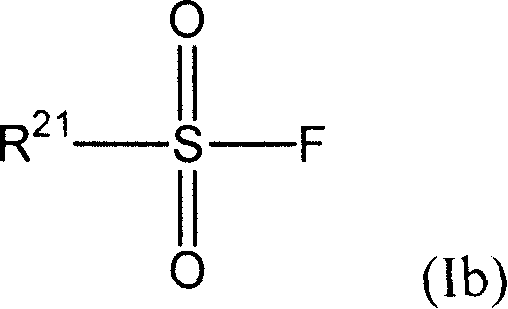

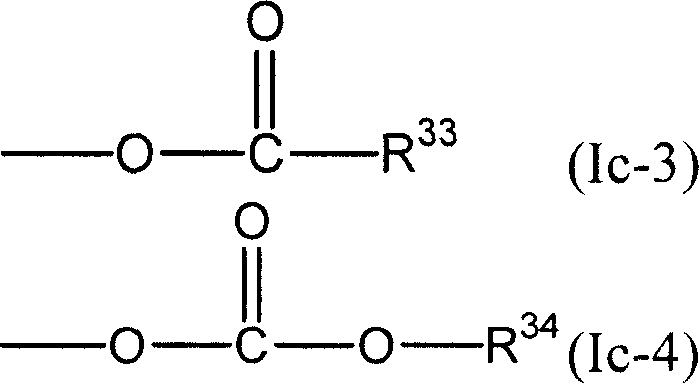

Method used

Image

Examples

preparation example Construction

[0247] [Preparation method of non-aqueous electrolyte (I)]

[0248] The non-aqueous electrolyte of the present invention is prepared by dissolving the above electrolyte, the unsaturated cyclic carbonate compound (component A), compound (I) (component B), and other auxiliary agents used as needed in the above non-aqueous solvent. I). Before preparing the non-aqueous electrolyte (I), it is desirable to pre-dehydrate each component such as a non-aqueous solvent. Specifically, it is desirable that the moisture content of each component after dehydration is 50 ppm or less, preferably 30 ppm or less. The method of dehydration can be arbitrarily selected, and examples of the method are heating under reduced pressure or passing through molecular sieves.

[0249] The non-aqueous electrolyte solution (I) of the present invention in a semi-solid state can also be prepared by gelation using a gelling agent such as a polymer. In the semi-solid electrolyte, the proportion of the non-aqueous ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com