Magnesia thin film, plasma display board using the same and manufacture method thereof

A technology of a display panel and a manufacturing method, which is applied to the manufacture of alternating current plasma display panels, discharge tubes/lamps, cold cathode manufacture, etc., can solve the problems of reduced sputtering resistance, reduced secondary electron emission coefficient, etc., to simplify the process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below, preferred embodiments are cited, and the technical features of the present invention are described in detail as follows in conjunction with the accompanying drawings. The contents of the present invention can be more easily understood from the following examples, which are only examples of the present invention and are not intended to limit the protection scope of the present invention.

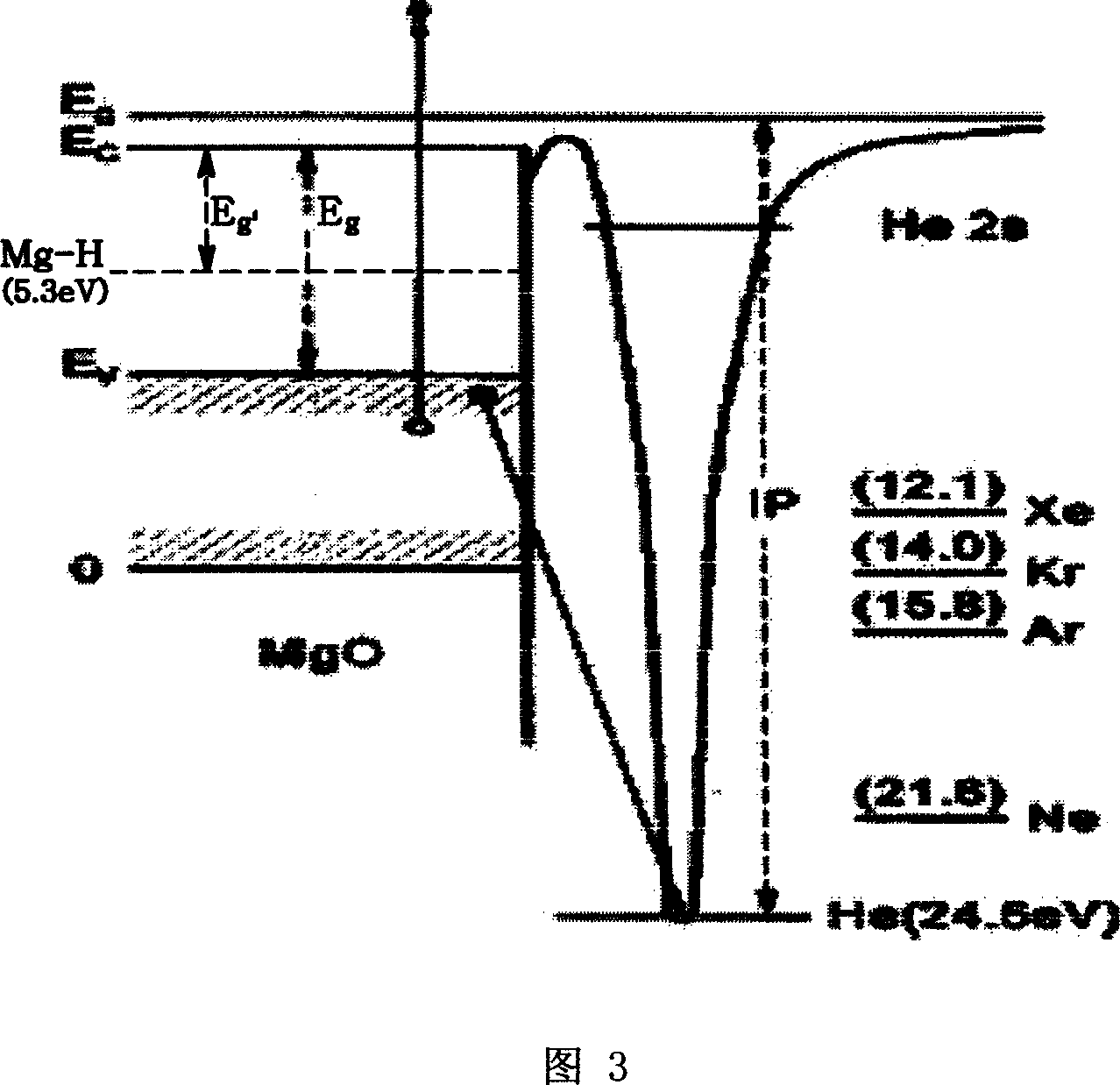

[0047] Fig. 2 is in the present invention, the energy level schematic diagram inside the magnesium oxide thin film crystal of plasma display panel, in order to emit secondary electrons from the magnesium oxide thin film, it is necessary to excite from the valence (electron) band (Valence Band) conduction band (Conduction Band) , requires the energy (E g ), as shown in the figure, the magnesium-hydrogen complex has a higher energy level (band gap (band gap) energy 5.3eV), therefore, using a magnesium-oxygen complex from the valence (electronic) band (Valence Band) The energy req...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com