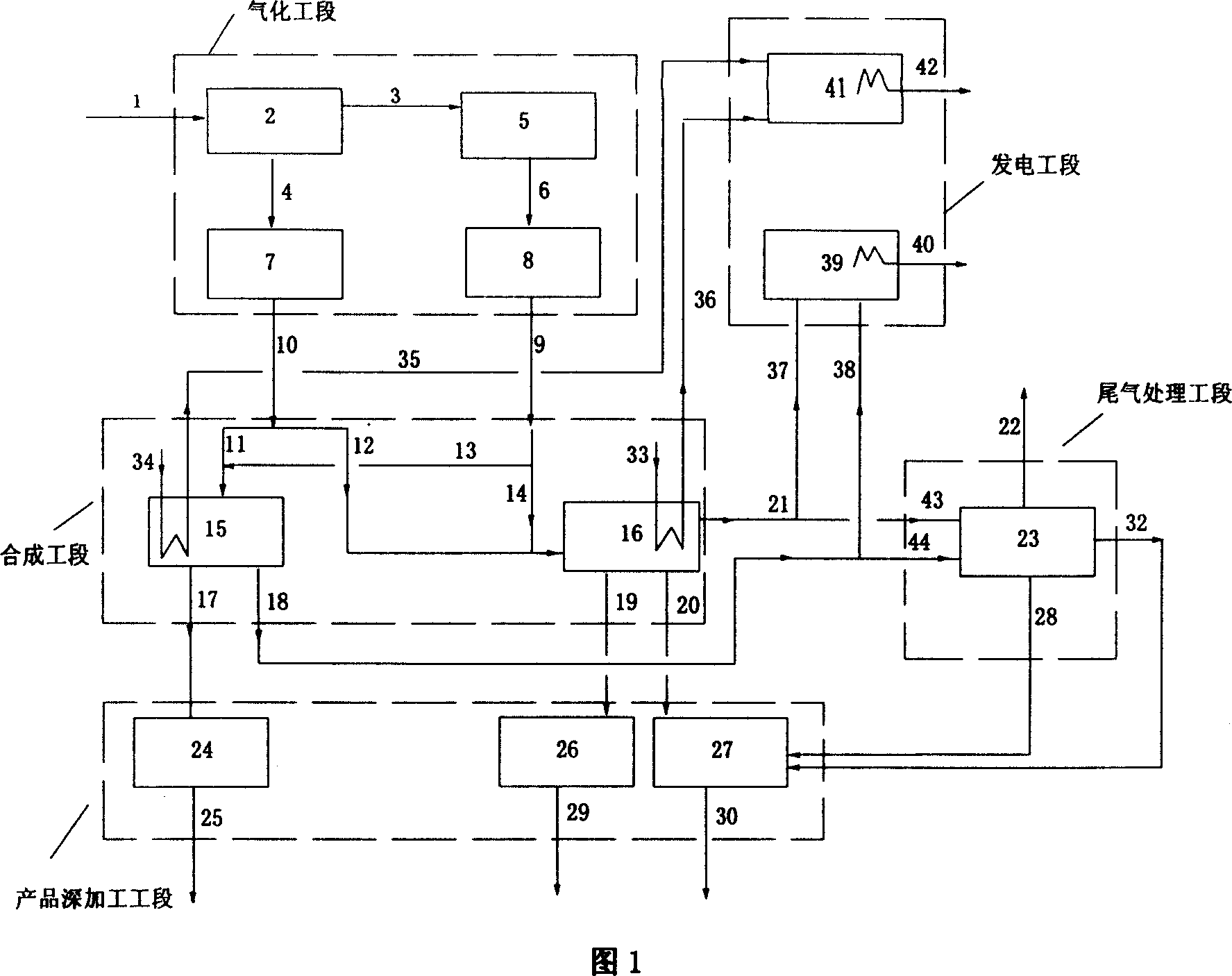

Method of coproducing oil product, methanol and electric energy using carbon containing combustible solid as raw material

A technology of oil products and raw materials, which is applied in the field of co-production of oil products, methanol and electric energy, can solve the problems of difficult coal handling, high sulfur emissions, etc., and achieve the effect of convenient product structure adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

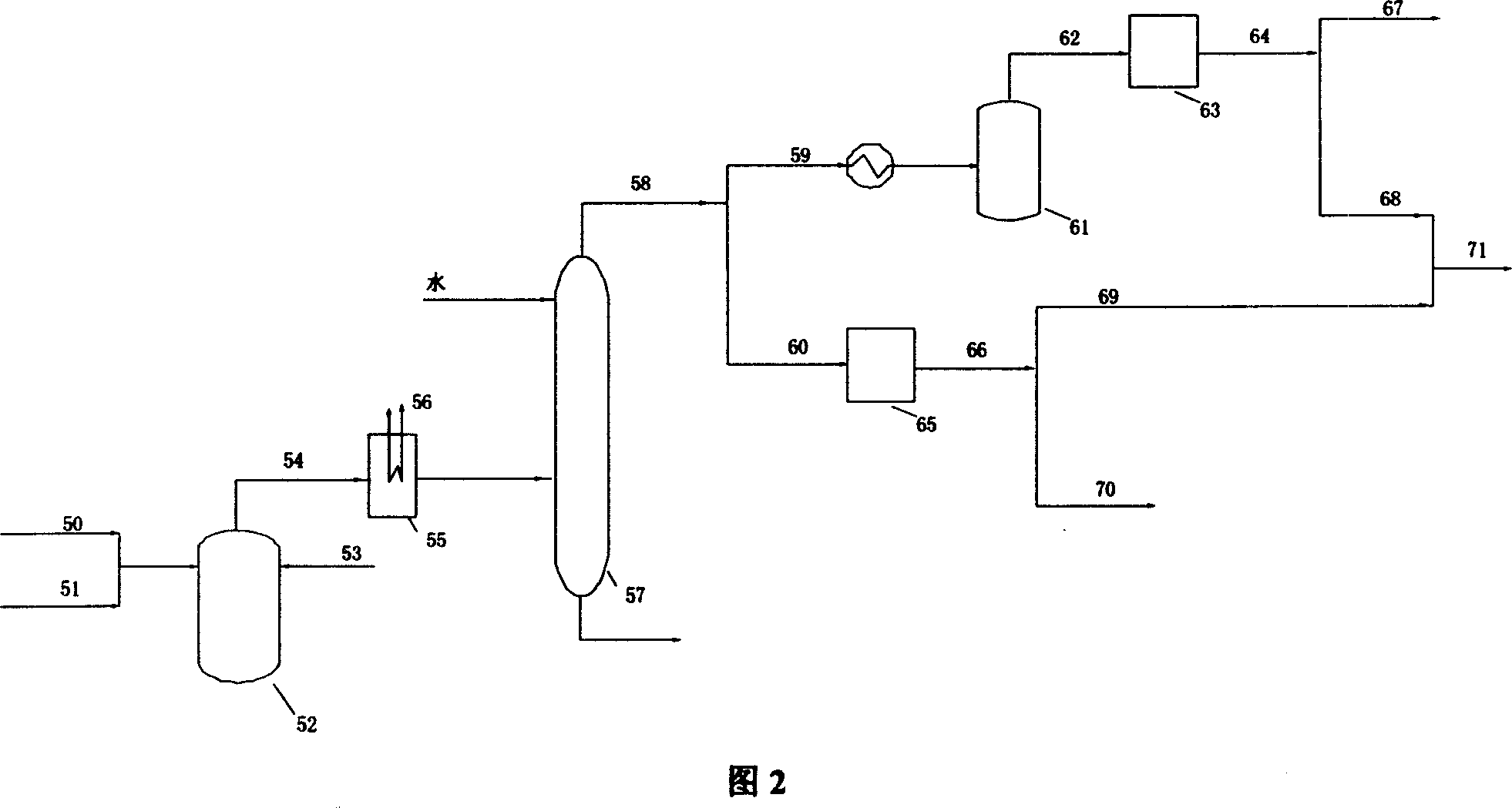

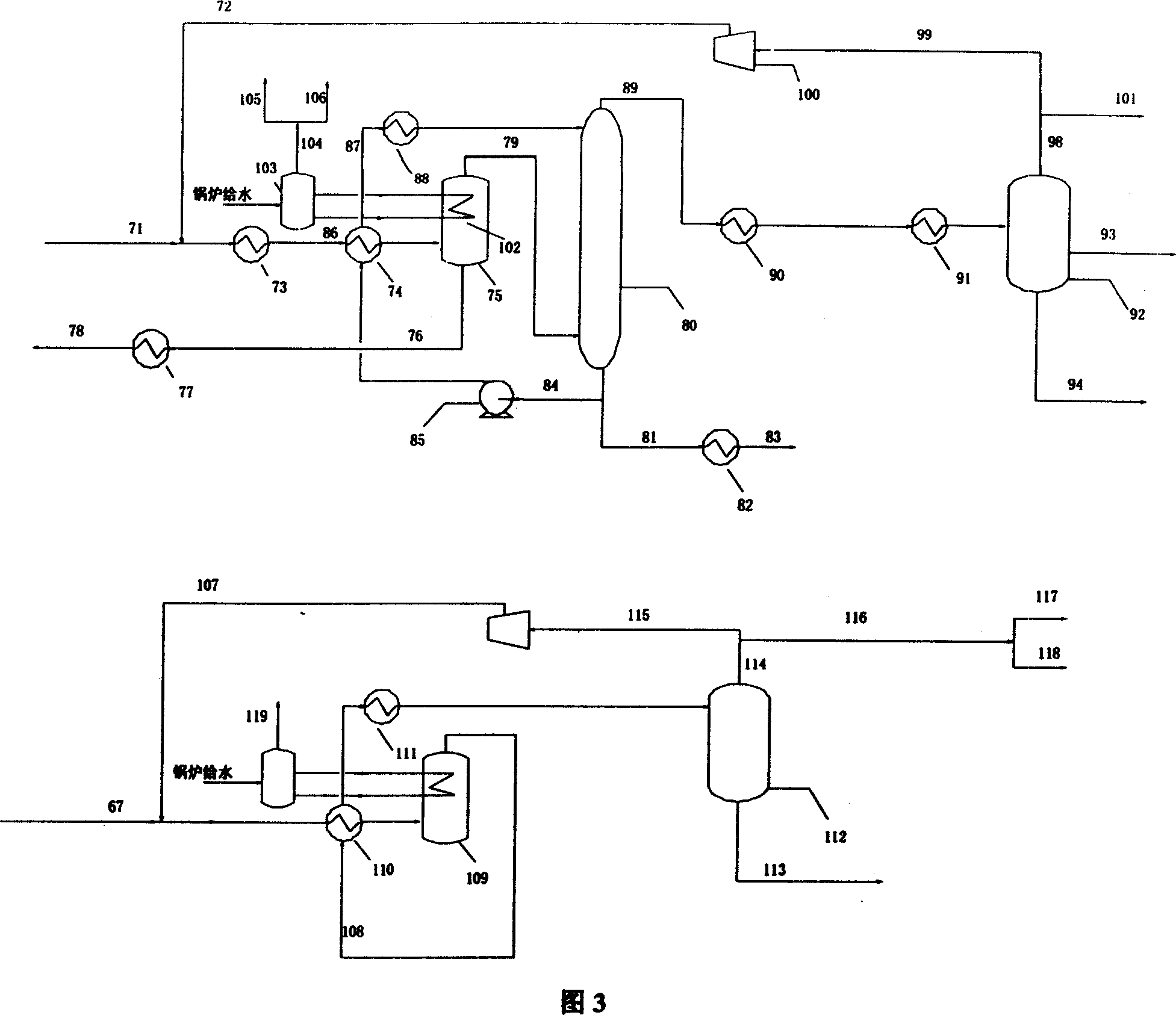

Embodiment 1

[0084] Figure 2 shows the gasification section. The coal 50 used as the raw material for gasification is 486t / h. After grinding, it is mixed with 321t / h of water 51 to form a coal-water slurry, which is sent to a group of coal-water slurry gasifiers 52 and mixed with 430t / h high-pressure oxygen from air separation. 53 Carry out partial oxidation reaction between 1350-1400°C to obtain crude synthesis gas 54 mainly composed of carbon monoxide and hydrogen. The crude synthesis gas 54 passes through the waste heat boiler unit 55 to recover heat, cools the gas to 660°C, and then enters the water washing tower 57 for washing and is saturated with water vapor and sent out of the boundary area. The by-product of this process is 1110t / h, 9.8MPa, 540°C steam 56, the by-produced steam is used for the work of the air compressor and supercharger turbine of the air separation unit; and from the air compressor and supercharger turbine Then extract the condensed steam to obtain 4.0MPa, 390℃ ...

Embodiment 2

[0112] The biggest difference between embodiment 2 and embodiment 1 is that the Fischer-Tropsch synthesis adopts a two-stage series structure, and the other units are similar to the previous embodiment.

[0113] The gasification section of Example 2 is shown in Figure 7. The preparation process, operating parameters, raw material consumption and crude gas production composition of the crude synthesis gas are the same as those in Example 1. The main difference from Example 1 is that all the unshifted synthesis gas is used for Fischer-Tropsch synthesis together with part of the shifted synthesis gas.

[0114] In the gasification furnace 223, coal 220 is used as gasification raw material, and water 221 is used to form a coal water slurry, and the coal gasification reaction is carried out with high-pressure oxygen 222 to obtain a crude synthesis gas 224 mainly composed of carbon monoxide and hydrogen. The amount of coal consumed is 486t / h, the amount of water is 321t / h, and the a...

Embodiment 3

[0147] The biggest difference between Example 3 and Example 1 is that a two-stage serial structure of Fischer-Tropsch synthesis reactor and methanol synthesis reactor is adopted, and the other units are similar to the previous example.

[0148] The gasification section is shown in Figure 12. The preparation process, operating parameters, raw material consumption and crude gas production composition of the crude synthesis gas are exactly the same as those in Examples 1 and 2. The main difference from the previous embodiment is that all the synthesis gas is converted and used as feed gas for the Fischer-Tropsch synthesis reactor.

[0149]In the gasification furnace 433, coal 430 is used as a gasification raw material, and water 431 is used to form a coal water slurry, and the coal gasification reaction is carried out with high-pressure oxygen 432 to obtain a crude synthesis gas 434 mainly composed of carbon monoxide and hydrogen. The amount of coal consumed is 486t / h, the amoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com