Cationic dehydrating agent and its preparation method

A cationic, dehydrating agent technology, applied in the direction of dehydration/drying/thickened sludge treatment, etc., can solve the problems of poor flocculation bridging ability and low molecular weight of flocculants, and achieve easy control, improved dehydration effect, and short reaction time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

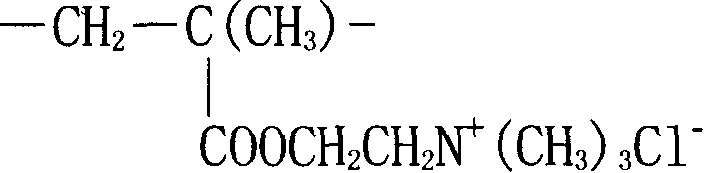

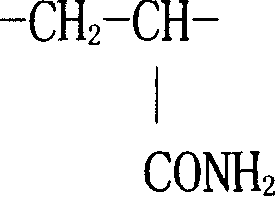

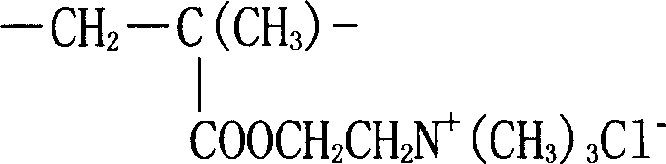

Embodiment 1

[0019] Into a 1000ml four-necked flask equipped with a thermometer, feeding tube, and nitrogen inlet and outlet, add 116.3g of acrylamide monomer, 44.6g of cationic monomer methacryloyloxyethyltrimethylammonium chloride, ethylenediaminetetra Disodium acetate (chemically pure) 0.45g, deionized water 500ml, blow nitrogen to remove dissolved oxygen, finally add N,N-dihydroxyethyl azobisisobutylamidine hydrochloride initiator 10 -4 mol / L, 0.3 g of ammonium persulfate (chemically pure) and 0.3 g of sodium bisulfite (chemically pure) were added, and the copolymerization reaction was carried out in a water bath at 40° C. for 4 hours. After the reaction is finished, it is extruded to granulate, dried and pulverized to obtain dehydrating agent-1.

Embodiment 2

[0021] Into a 1000ml four-neck flask equipped with a thermometer, feeding tube, and nitrogen inlet and outlet, add 96.9g of acrylamide monomer, 33.8g of cation monomer methacryloyloxyethyltrimethylammonium chloride, ethylenediaminetetra Disodium acetate (chemically pure) 0.38g, deionized water 500ml, blowing nitrogen to remove dissolved oxygen, finally add N, N-dihydroxyethyl azobisisobutylamidine hydrochloride initiator 5 * 10 -4 mol / L, 0.5 g of ammonium persulfate (chemically pure) and 0.4 g of sodium bisulfite (chemically pure) were added, and copolymerization was carried out in a water bath at 35° C. for 6 hours. After the reaction is finished, it is extruded to granulate, dried and pulverized to obtain dehydrating agent-2.

Embodiment 3

[0023] Into a 1000ml four-necked flask equipped with a thermometer, feeding tube, and nitrogen inlet and outlet, add 131.3g of acrylamide monomer, 25.3g of cationic monomer methacryloyloxyethyltrimethylammonium chloride, ethylenediaminetetra Disodium acetate (chemically pure) 0.55g, deionized water 500ml, blow nitrogen to remove dissolved oxygen, finally add N, N-dihydroxyethyl azobisisobutylamidine hydrochloride initiator 10 -4 mol / L, add 0.35 g of ammonium persulfate (chemically pure), and carry out copolymerization reaction for 5 hours in a water bath at 55°C. After the reaction is finished, it is extruded to granulate, dried and pulverized to obtain dehydrating agent-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com