Modified montmorillonite, preparation method and application

A montmorillonite and modified technology, used in pharmaceutical formulations, active ingredients of aluminum/calcium/magnesium, drug delivery, etc., can solve the problem of no treatment for chronic atrophic gastritis reversal, no treatment for chronic atrophic gastritis. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0147] Embodiment 1 Preparation of modified montmorillonite

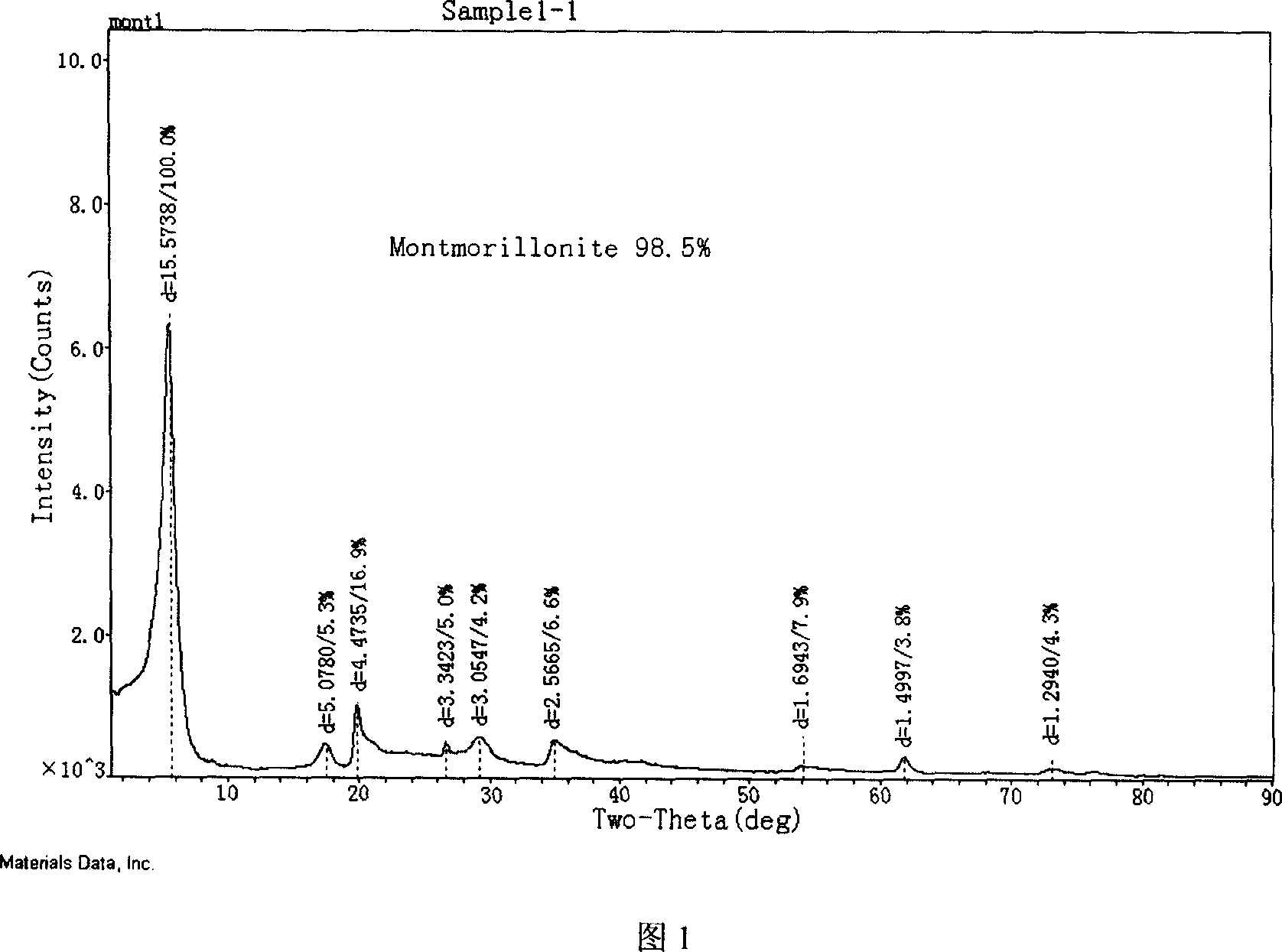

[0148] The phase analysis of purified montmorillonite is shown in Figure 1.

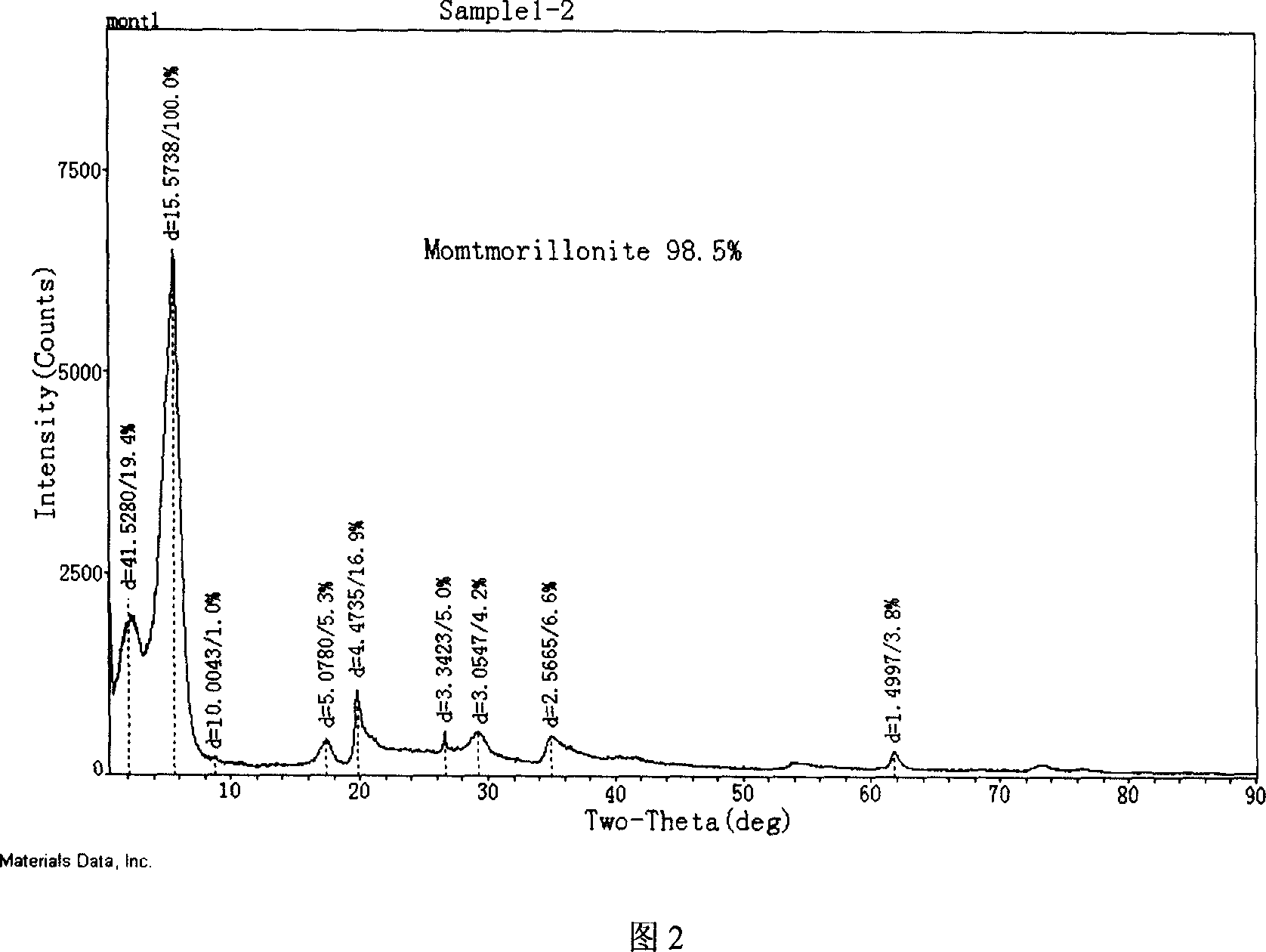

[0149] In the purification of montmorillonite, add a mixed acid with a concentration of 2mol / L, the composition of the mixed acid is (the molar ratio of hydrochloric acid: oxalic acid: acetic acid is 4:10:6), and the mass ratio of soil: acid is 1:3. Mix, boil at 100°C for 5-6 hours, filter to remove the mixed acid, wash the filter cake with deionized water to pH ≥ 4, dry at 100°C, and grind it into 300-500 mesh to obtain the modified calcium base For montmorillonite, see Figure 2 for its abundance or phase analysis.

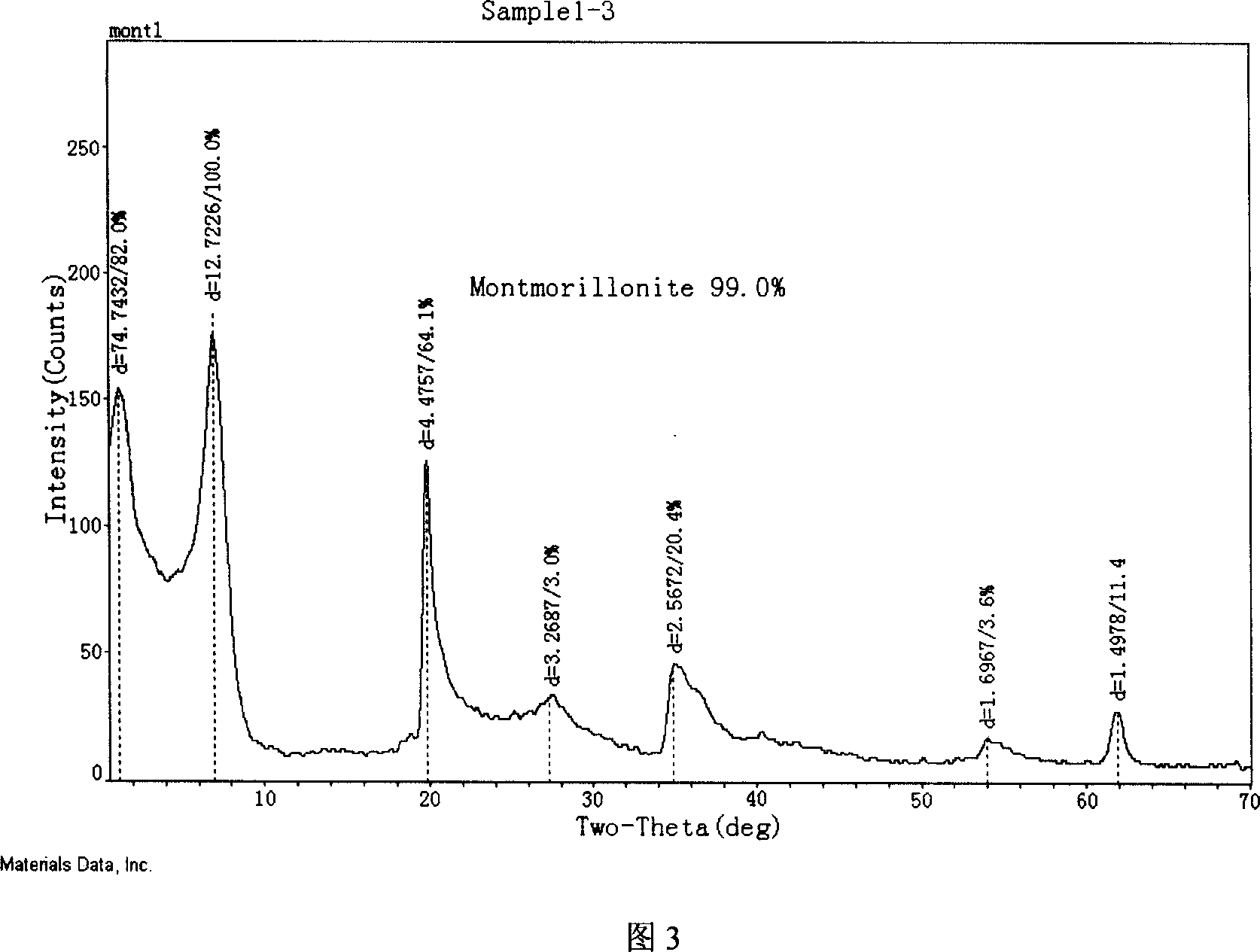

[0150] Prepare the obtained modified calcium-based montmorillonite with 0.5N hydrochloric acid solution to make a slurry with a solid content of 20%, stir for 6 hours, filter to remove the acid solution, wash the filter cake with hot water at 60°C until the pH is about 5, press Filter into a filter cake with a solid content o...

Embodiment 2

[0151] Example 2 Preparation of modified montmorillonite

[0152] The phase analysis of purified montmorillonite is shown in Figure 4.

[0153] In the purification of montmorillonite, add a mixed acid with a concentration of 1mol / L, the composition of the mixed acid is (the molar ratio of hydrochloric acid: oxalic acid: acetic acid is 3:4:3), and the mass ratio of soil: acid is 1:4. Mix, boil at 90°C for 6-8 hours, filter to remove the mixed acid, wash the filter cake with deionized water to pH ≥ 4, dry at 120°C, and grind it into 300-500 mesh to obtain the modified calcium base For montmorillonite, see Figure 5 for its abundance or phase analysis.

[0154] The obtained modified calcium-based montmorillonite was mixed with 0.5N sulfuric acid solution to make a slurry with a solid content of 15%, stirred for 6 hours, filtered to remove the acid solution, and the filter cake was washed with hot water at 70°C until the pH was about 5.5. Pressure filtration into a filter cake wi...

Embodiment 3

[0155] Example 3 Preparation of modified montmorillonite

[0156] Mineral composition of raw bentonite: see Figure 8.

[0157] The raw ore is dried, crushed, passed through a 50-mesh sieve, added water and 0.3% sodium hexametaphosphate of raw ore powder to form a slurry with a solid content of 20%, stirred for two hours, passed through a three-stage hydrocyclone, and separated The slurry is mixed with water to make a thin slurry with a solid content of 3%, which is separated in a disc centrifuge, and the separated thin slurry is concentrated in another disc centrifuge, and the concentrated slurry is passed through a plate and frame filter press After pressure filtration, a filter cake with a solid content of 40-50% was obtained. The filter cake was dried at 125° C. and crushed to a size above 500 mesh. The mineral composition of the purified montmorillonite is shown in FIG. 8 .

[0158] In the purification of montmorillonite, add a mixed acid with a concentration of 2mol / L (t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com