Method for preparing uridine diphosphate

A technology of uridine diphosphate and uridine triphosphate, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of cost increase, low recovery rate, and long cycle, so as to reduce burden, The effect of improving product recovery rate and shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

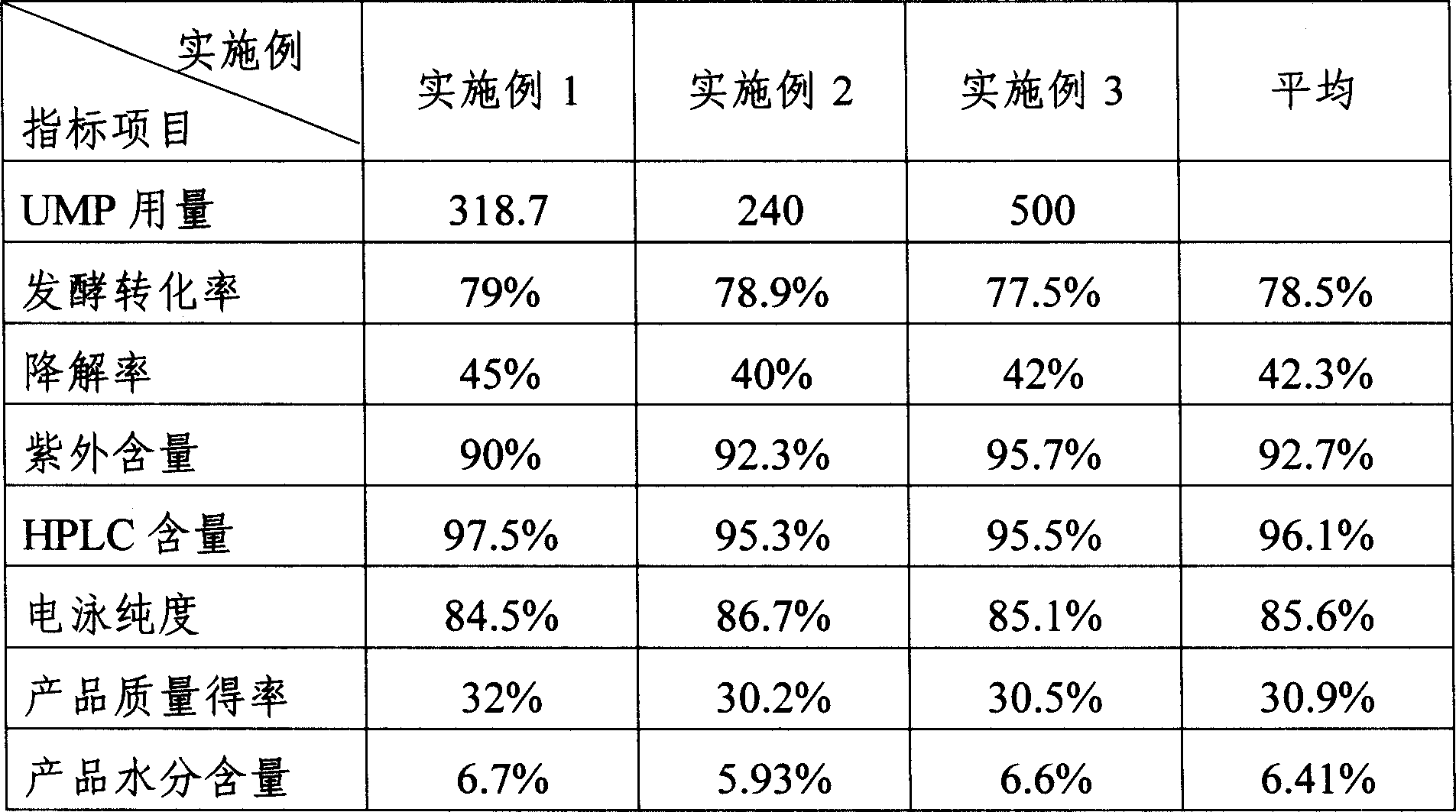

Embodiment 1

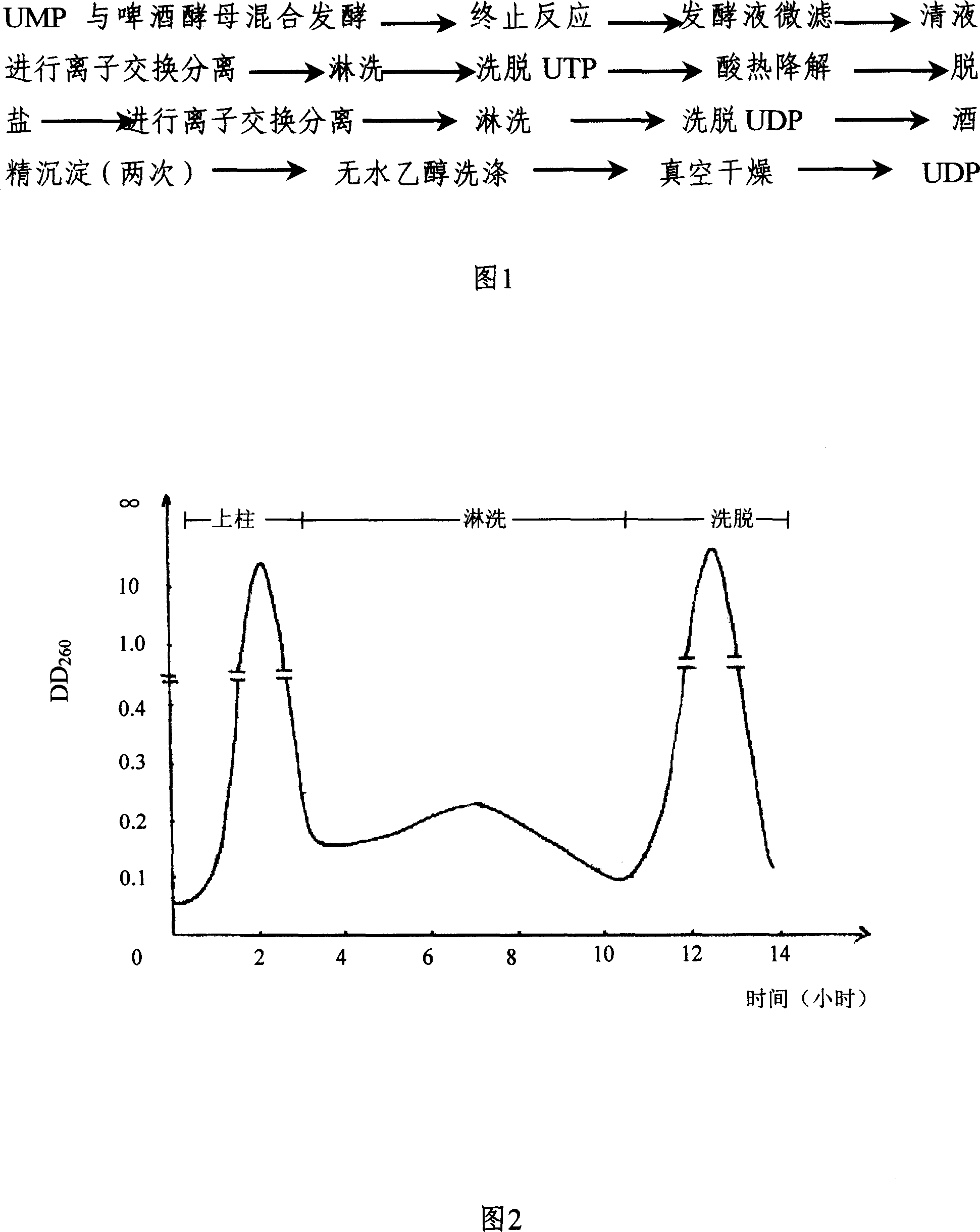

[0060] Fig. 1 is the production process of uridine diphosphate of the present invention; the present embodiment adopts the method of primary fermentation and degradation to produce uridine diphosphate.

[0061] 1. Fermentation

[0062] First, adopt one-step method to ferment uridine monophosphate (6-liter scale), fermentation conditions: UMP318.7g (feeding according to electrophoretic purity 75.3%); Saccharomyces cerevisiae 3kg; Glu 432g; NaH 2 PO 4 280.8g; MgCl 2 24.4g; pH6.7; H 2 Add O to 6 liters; keep warm at 37°C, and ferment statically for 6 hours.

[0063] Brewer's yeast is eliminated yeast in beer production, and the survival rate of yeast cells is more than 98%, and the content (percentage by weight) of yeast in the dried yeast after pressing is 25%.

[0064] Then use fast paper electrophoresis to track and detect the fermentation products.

[0065] The pH value was adjusted to 2.0 with trichloroacetic acid, the fermentation was terminated, and the fermentation...

Embodiment 2

[0105] 1. Fermentation

[0106] First, adopt one-step method to ferment uridine monophosphate (5 liter scale), fermentation conditions: UMP 240g (feeding according to electrophoretic purity 75.3%); Saccharomyces cerevisiae 2.4kg; Glu 312g; NaH 2 PO 4 216g; MgCl 2 57.1g; pH6.2; H 2 Add O to 5 liters; keep warm at 32°C and ferment statically for 8 hours.

[0107] Brewer's yeast is eliminated yeast in beer production, and the survival rate of yeast cells is more than 90%, and the yeast content (percentage by weight) in the dried yeast after pressing is 20%.

[0108] Then use fast paper electrophoresis to track and detect the fermentation products.

[0109] The pH value was adjusted to 3.0 with trichloroacetic acid to terminate the reaction, and the fermentation conversion rate was 78.9%.

[0110] 2. Microfiltration to remove protein:

[0111] Use an inorganic ceramic membrane with a pore size of 0.1 μm to treat the fermentation broth. Before microfiltration, pass through a...

Embodiment 3

[0148] The basic steps are the same as in Example 1, except that during one-step fermentation, fermentation conditions: UMP 500g (feeding according to electrophoretic purity 75.3%); brewer's yeast (fresh) 3.5kg; Glu 493.8g; NaH 2 PO 4 360g; MgCl 2 5.71g; pH7.0; H 2 Add O to 8 liters; keep warm at 39°C, and ferment statically for 7 hours. The fermentation conversion rate was 77.5%.

[0149] When using 717 chlorine-type strong base anion exchange resin for UTP separation and purification, the upper column: pH2.5, the upper column flow rate is 26L / hr; low-salt elution: 0.02N, pH2.0 NaCl solution; the elution flow rate is 26L / hr hr; high salt elution: 0.5N NaCl, pH2.0 solution; elution flow rate 2.8L / hr.

[0150] Loading volume: 2.36% of the total exchange volume of 717 resin, that is, 40mg UTP / ml resin,

[0151] During acid-thermal degradation, the pH value was first adjusted to 1.2 with 6N hydrochloric acid, heated and boiled for 30 minutes, and detected by high performan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com