High power LED flip-chip and its manufacturing method

A flip-chip, high-power technology, applied to semiconductor devices, electrical components, circuits, etc., can solve the problems of P-GaN doping concentration is difficult to achieve, lack of work function, etc., and achieve the effect of improved heat dissipation and high reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The wavelength range of the high-power LED flip chip of the present invention is 430nm-530nm.

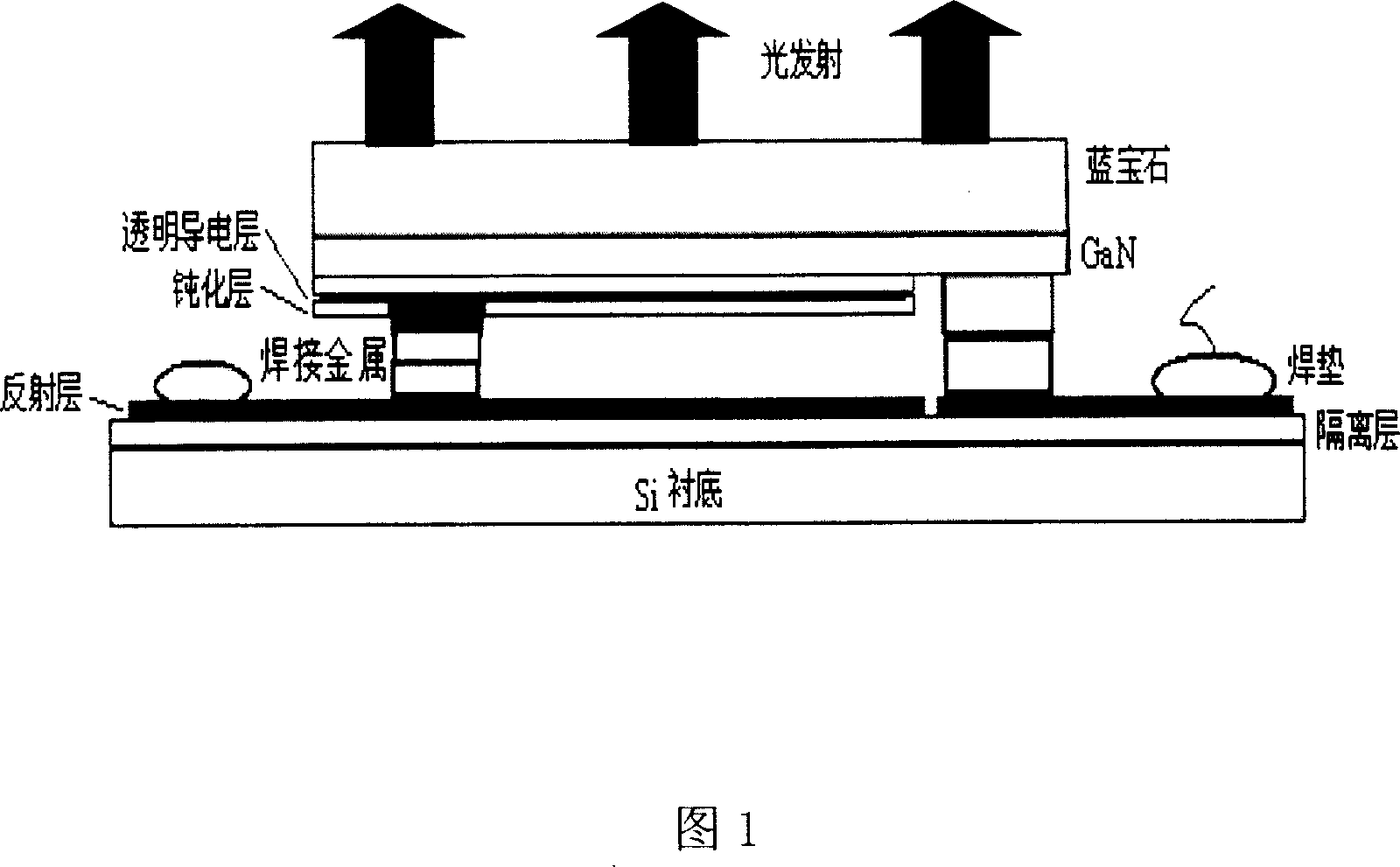

[0027] As shown in Figure 1, the high-power LED flip-chip of the present invention is composed of P-N electrode epitaxial wafers and a silicon substrate with a reflective layer.

[0028] The P-N electrode epitaxial wafer includes a sapphire substrate, and the sapphire substrate has the characteristics of low thermal conductivity and insulation. The N-GaN layer formed on the sapphire substrate, the P-GaN layer and the light-emitting layer formed on the N-GaN layer (the light-emitting layer is located between the N-GaN layer and the P-GaN layer), so as to be compatible with the N-GaN layer make electrical contact.

[0029] For flip-chip LEDs, light is sent from a transparent sapphire substrate, which requires high light transmittance to the transparent conductive layer. Due to the limited electrical conductivity of the P-GaN layer, the present invention deposits one more layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com