A proton-exchange film fuel battery electrocatalyst and its preparing and application

A proton exchange membrane, fuel cell technology, applied in catalyst activation/preparation, battery electrodes, physical/chemical process catalysts, etc., can solve the problems of high Pt price, lack of resources, poisoning, etc., and achieve low price, abundant resources, and preparation. simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

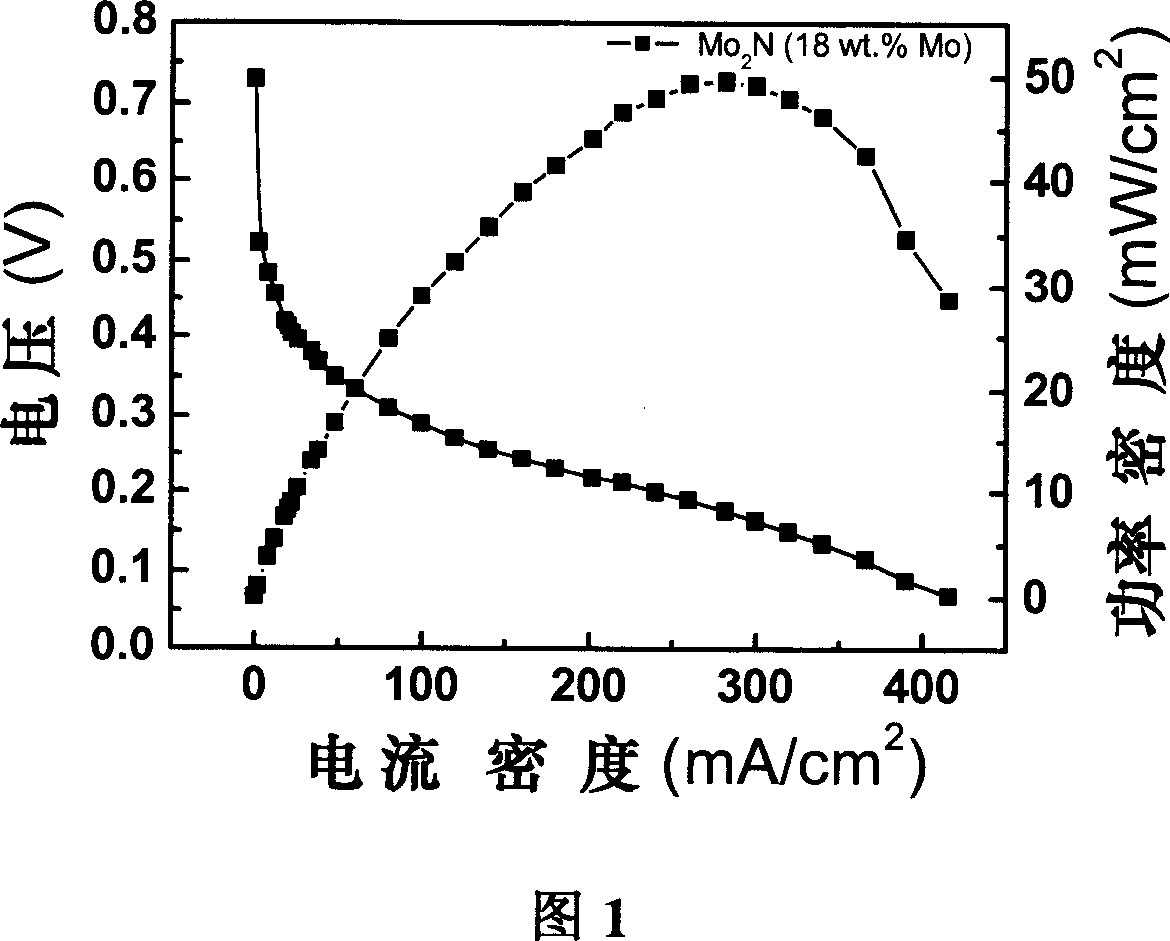

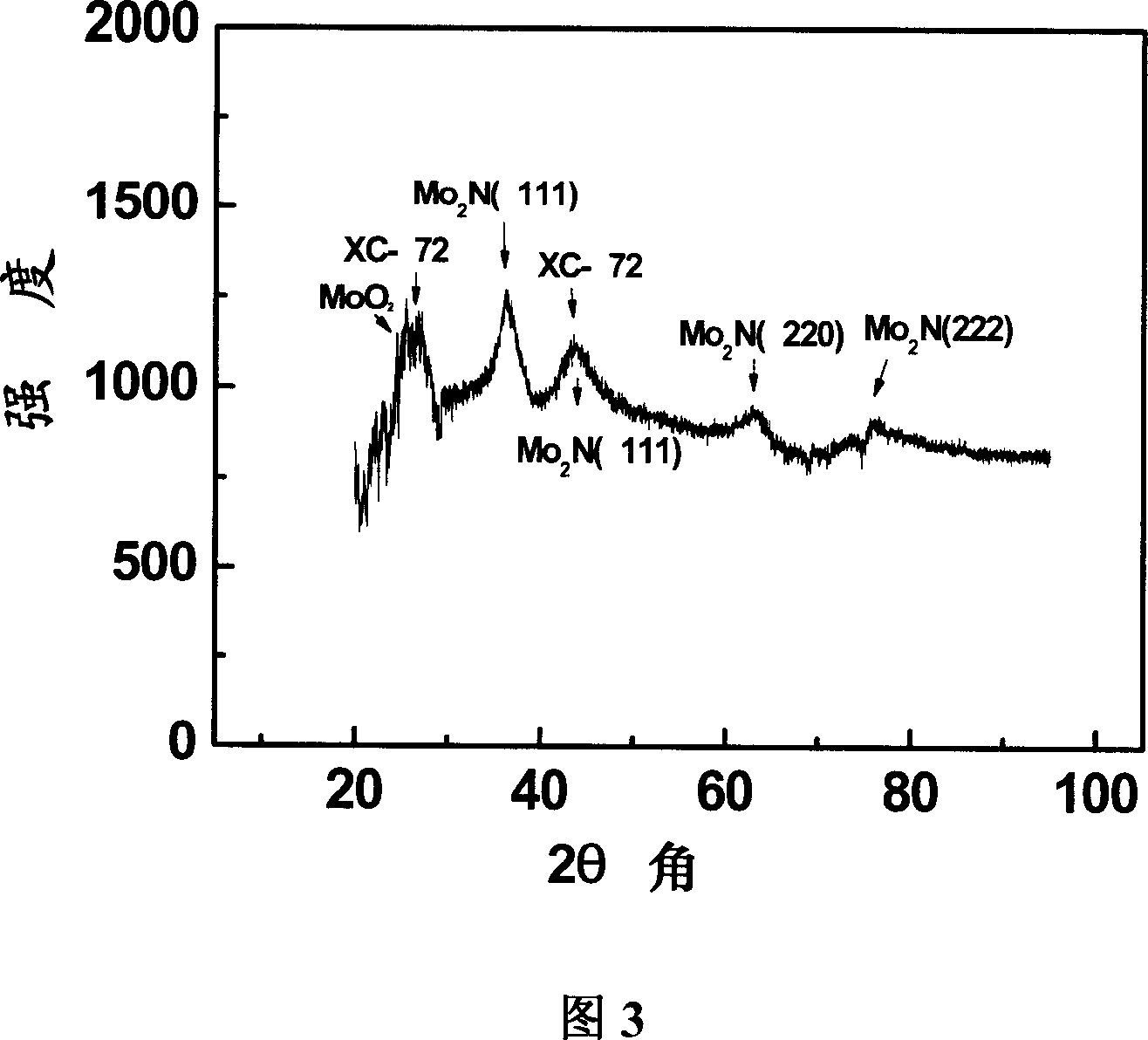

Embodiment 1

[0029] Take 0.83ml of ammonium molybdate aqueous solution with a concentration of 133.6mgMo / ml, add appropriate amount of water and isopropanol and ultrasonically mix it evenly, then add it to 0.5g Vulcan XC-72, stir for half an hour to mix evenly, and soak it for 12h. The above mixture was slowly evaporated on a water bath at 90°C until the surface was dry, and then dried in a vacuum oven at 120°C for 2 hours; then the sample was moved into a tube furnace for sintering and nitriding. The roasting condition is N 2 In the atmosphere, the temperature was raised to 500°C at a constant temperature of 5°C / min for 2 hours, and then lowered to room temperature. Then pass 60ml / min of NH 3 Raise the temperature from room temperature to 623K at 5K / min; then raise the temperature from 623K to 723K at a speed of 0.5K / min, and then raise the temperature from 723K to 973K at 2.5K / min, then keep the temperature at 973K for 2 hours, and then lower it to room temperature to prepare (18wt. %M...

Embodiment 2

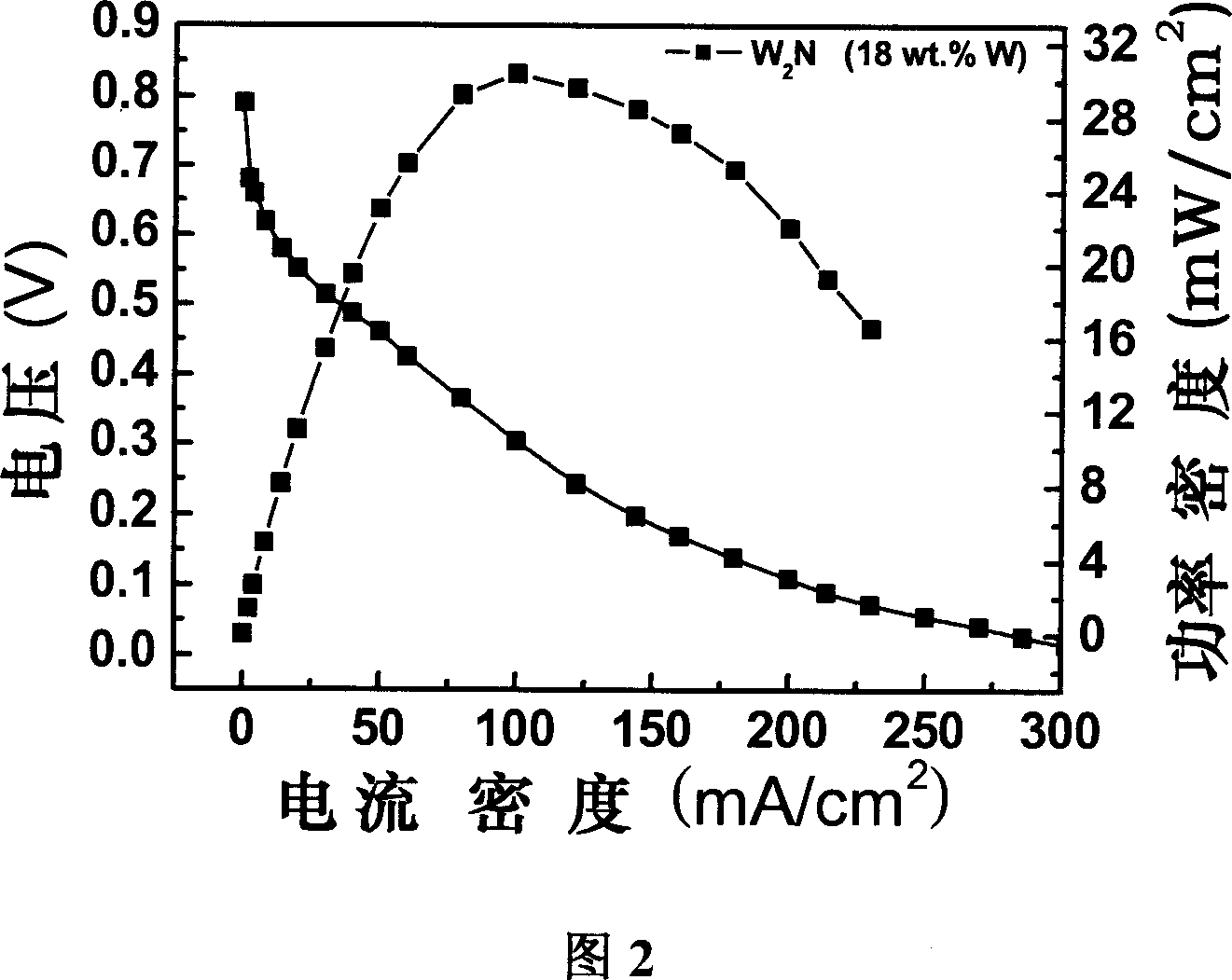

[0033] Take 0.25ml of ammonium metatungstate aqueous solution with a concentration of 441.216mgW / ml, add 1.5ml of water and 0.3ml of isopropanol and ultrasonically mix it evenly, then add it into 0.5gXC-72, stir for half an hour to mix evenly, and soak it for 12h . The above mixture was slowly evaporated on a water bath at 90°C until the surface was dry, and then dried in a vacuum oven at 120°C for 12 hours; then the sample was moved into a tube furnace for sintering and nitriding. The roasting condition is N 2 In the atmosphere, the temperature was raised to 500°C at a constant temperature of 5°C / min for 2 hours, and then lowered to room temperature. Then pass 60ml / min of NH 3 Raise the temperature from room temperature to 623K at 5K / min; then raise the temperature from 623K to 723K at a speed of 0.5K / min, and then raise the temperature from 723K to 1025K at 2.5K / min, then keep the temperature at 1025K for 2 hours, and then lower it to room temperature to prepare (18wt. %W...

Embodiment 3

[0036] The precursor oxide of supported cobalt molybdenum nitride is impregnated: 0.59ml of Co(NO with a concentration of 134.4mgCo / ml 3 ) 2 ·6H 2 O aqueous solution was slowly added to 0.96ml of ammonium molybdate aqueous solution with a concentration of 133.6mgMo / ml, and the mixed solution was immersed in 0.5g of XC-72, stirred for half an hour to mix evenly, and immersed for 12 hours. The above mixture was slowly evaporated on a water bath at 90°C until the surface was dry, and then dried in a vacuum oven at 120°C for 12 hours; then the sample was moved into a tube furnace for sintering and nitriding. The roasting condition is N 2 In the atmosphere, the temperature was raised to 500°C at a constant temperature of 5°C / min for 2 hours, and then lowered to room temperature. Then pass 60ml / min of NH 3 Raise the temperature from room temperature to 623K at 10K / min; then raise the temperature from 623K to 723K at a speed of 0.5K / min, then raise the temperature from 723K to 97...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com