Solid state fermentation process for producing product with rich probiotics polypeptide

A solid-state fermentation, probiotic technology, applied in microorganism-based methods, biochemical equipment and methods, fermentation, etc., can solve the problems of high production cost, high energy consumption, complex production process, etc., and achieve low equipment investment and production technology. Simple and effective in enhancing antioxidant enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

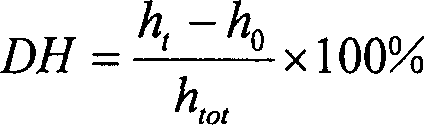

[0030] Example 1: Take 10Kg of soybean meal, grind it through an 80-mesh sieve, add 0.2% to 0.8% of acid protease, 0.08% of neutral protease, and 0.08% of cellulase, inoculate 0.5% of lactic acid bacteria starter, and adjust the water content to 50% with water ~55%, 35~37°C for 60~72 hours of airtight fermentation, the pH of the final product is 3.8~4.0, the degree of hydrolysis reaches about 12.5%, and the fermented product is obtained by drying.

Embodiment 2

[0031] Embodiment 2: Get 10Kg of peanut meal, pulverize and pass through a 60-100 mesh sieve, add 0.1%-0.6% of acid protease, 0.05% of neutral protease, 0.05% of cellulase, inoculate 1% of lactic acid bacteria starter, adjust the content with tap water The water content is 55%-60%, and the fermentation is airtight at 35-37°C for 70-75 hours. The pH of the final product is 4.0, the degree of hydrolysis reaches about 13%, and the fermented product is obtained by drying.

Embodiment 3

[0032] Embodiment 3: Get 10Kg of corn gluten powder, add acidic protease 1%, neutral protease 0.5%, inoculate lactic acid bacteria starter 3%, adjust water content to 55%~60% with tap water, 35~37 ℃ of airtight fermentation 60~80 hour, the pH of the final product is 4.0, the degree of hydrolysis reaches about 13%, and the fermented product is obtained by drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com