New cleanproduction process for extracting saponin from dioscorea zingiberensis

A technology of clean production and Dioscorea officinale, applied in the direction of steroids, organic chemistry, etc., can solve the problems of high production cost, no added value, loss of sapogenin from cleaning times, and long extraction time, so as to increase by-product income and drug utilization. The effect of increasing the rate and increasing the extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

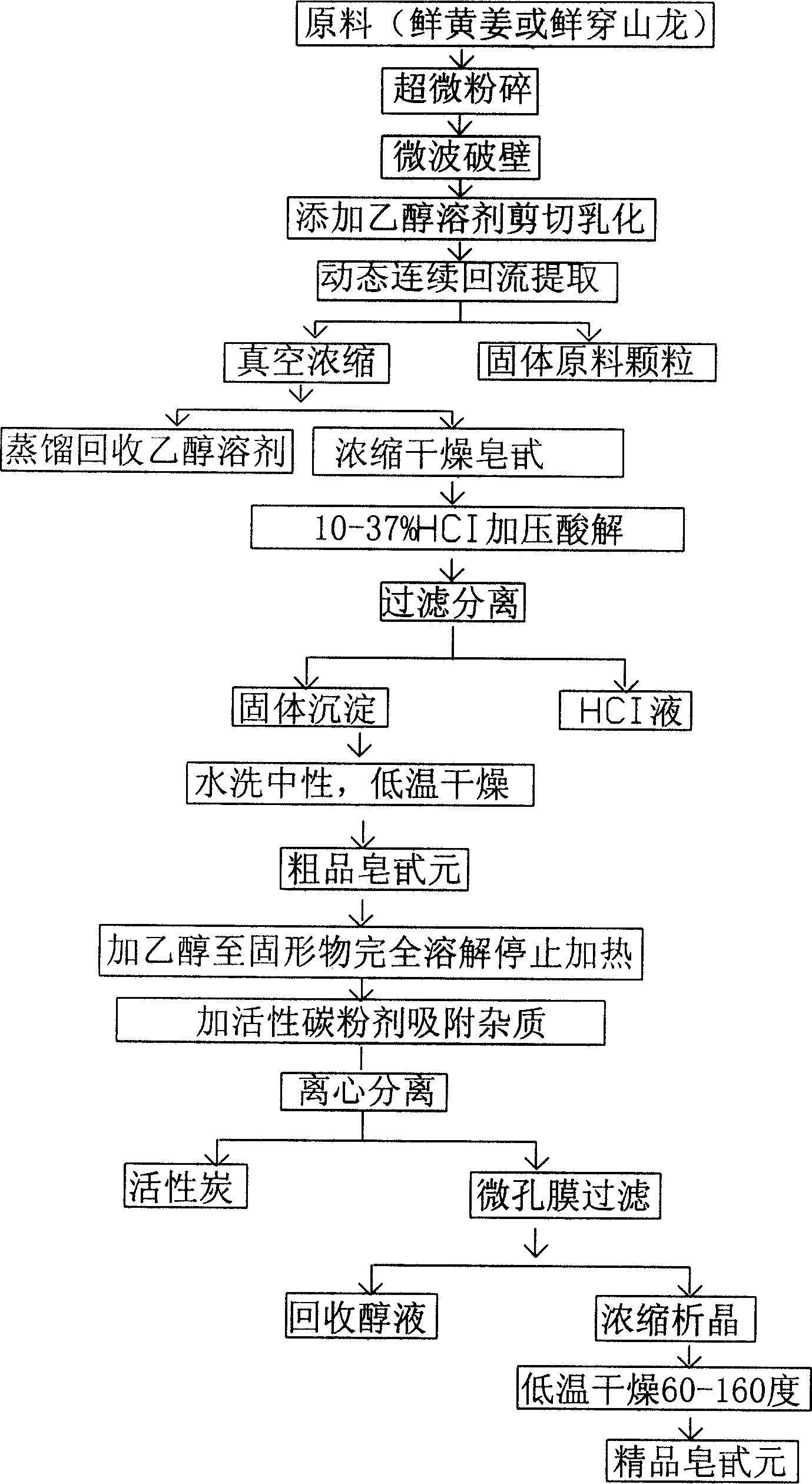

Image

Examples

Embodiment

[0045] Weigh 1000Kg of fresh turmeric, slice it after cleaning, break the wall with microwave equipment, put the material into a high-shear emulsification tank, and add ethanol solvent to shear for 30 minutes. Emulsified to 400 mesh. Dynamic continuous extraction equipment is used to cyclically extract materials to extract water-soluble saponins; the saponin solution is vacuum-concentrated and dried to obtain total saponins as residues. Add water to suspend, add 20% hydrochloric acid and heat to react for 6 hours. Filter out the acid solution, wash the acid solution precipitate with water until neutral, and dry to obtain crude saponin. Add absolute ethanol to dissolve crude aglycone, and add active carbon powder of equal weight to absorb impurities. Activated carbon powder was separated by filtration, and the filtered solvent was filtered through a microporous membrane to remove impurities, and the solvent was evaporated under reduced pressure to completely precipitate needle-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com